Multi-degree of freedom spherical traveling wave-type ultrasonic motor

A technology of ultrasonic motors and spherical motors, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as complex structure, limited practicality, and difficult implementation. Achieve the effects of simplified mechanical structure, simple overall structure, and convenient attitude control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

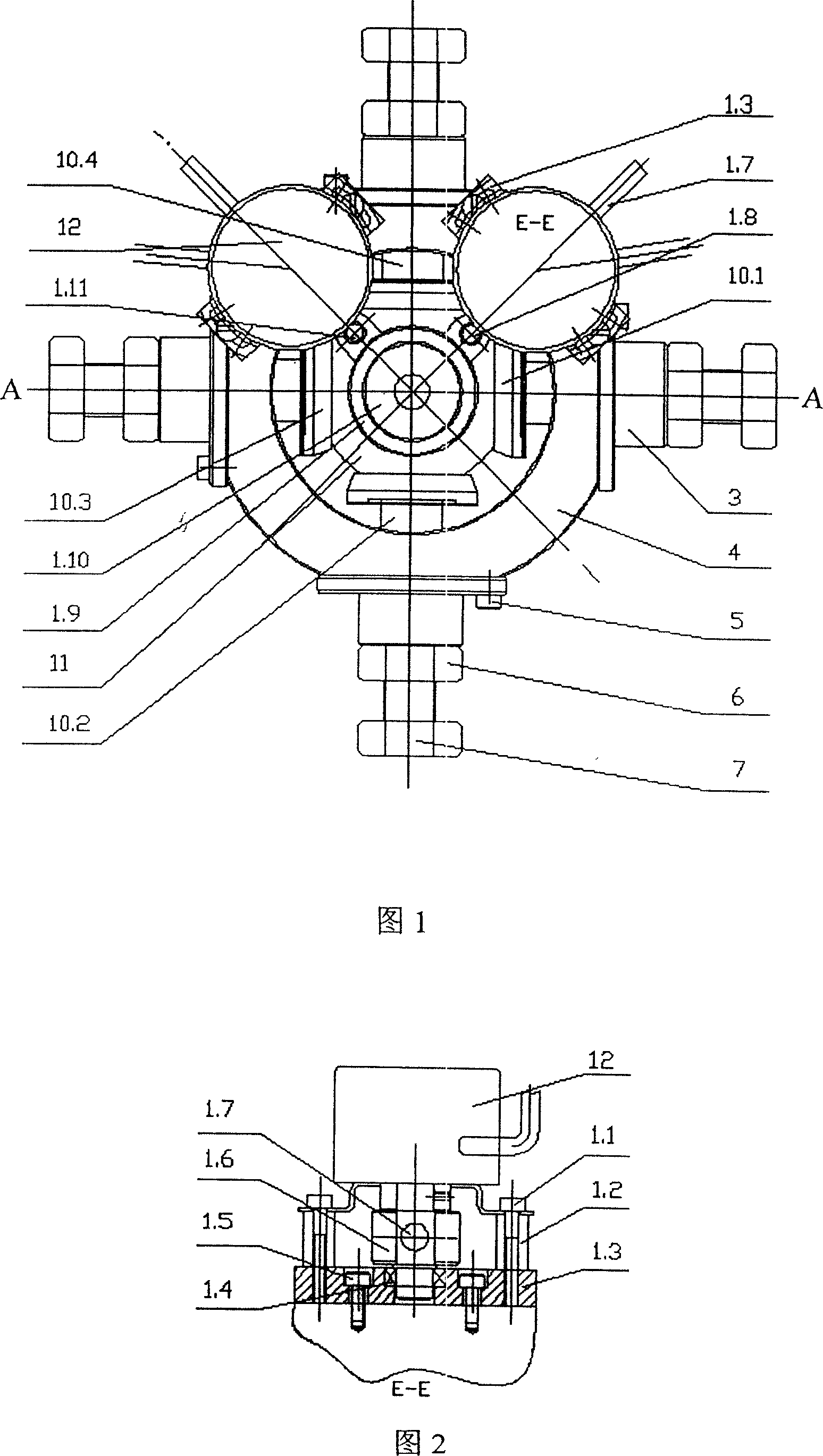

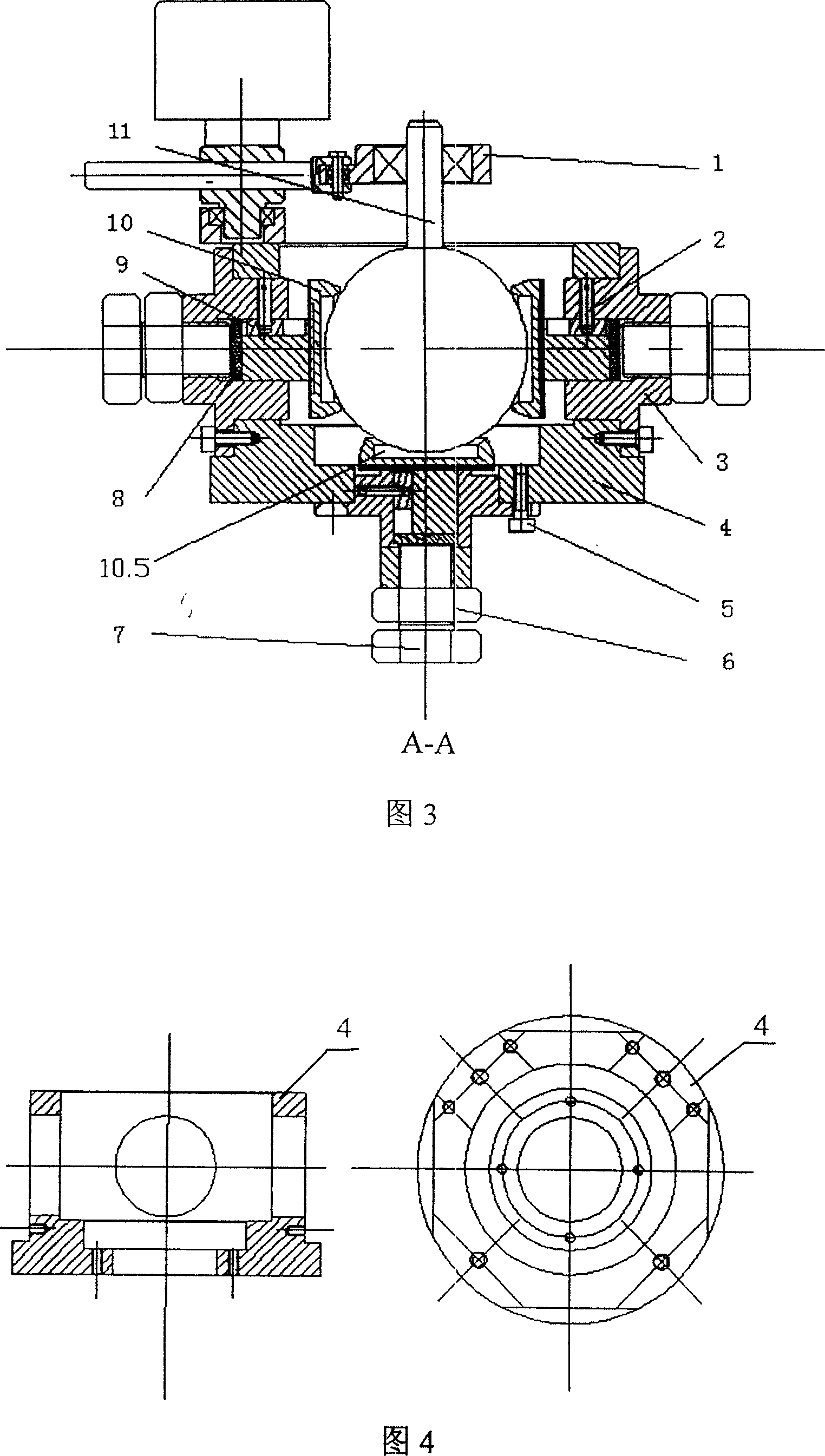

[0020] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention installs a spherical motor rotor 11 in the motor body 4, and installs a traveling wave stator at the front, rear, left, right and bottom of the spherical motor rotor 11 10.1, 10.2, 10.3, 10.4, 10.5 The inner spherical surface is matched with the spherical motor rotor 11, the five traveling wave stators are installed on the motor body 4 through their respective stator connecting parts, and the output shaft of the spherical motor rotor 11 is installed with mutual 90° attitude angle detection mechanism.

[0021] The stator connecting parts: each includes a stator connecting piece 3, an adjusting screw 6 and a nut 7; the tail of the traveling wave stator is loaded into the stator connecting 3, an elastic body 8 is installed between the tail and the adjusting bolt 6, and the stator is connected Part 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com