Method and device for precisely controlling axial fiber polishing thickness

A precise control and optical fiber technology, which is applied in the control of workpiece feed movement, grinding machines, manufacturing tools, etc., can solve the problems of fiber optic grinding length limitation, high technical level requirements, difficult to meet the requirements, etc., to improve processing capacity and Improve work efficiency, achieve simultaneous grinding, and eliminate roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

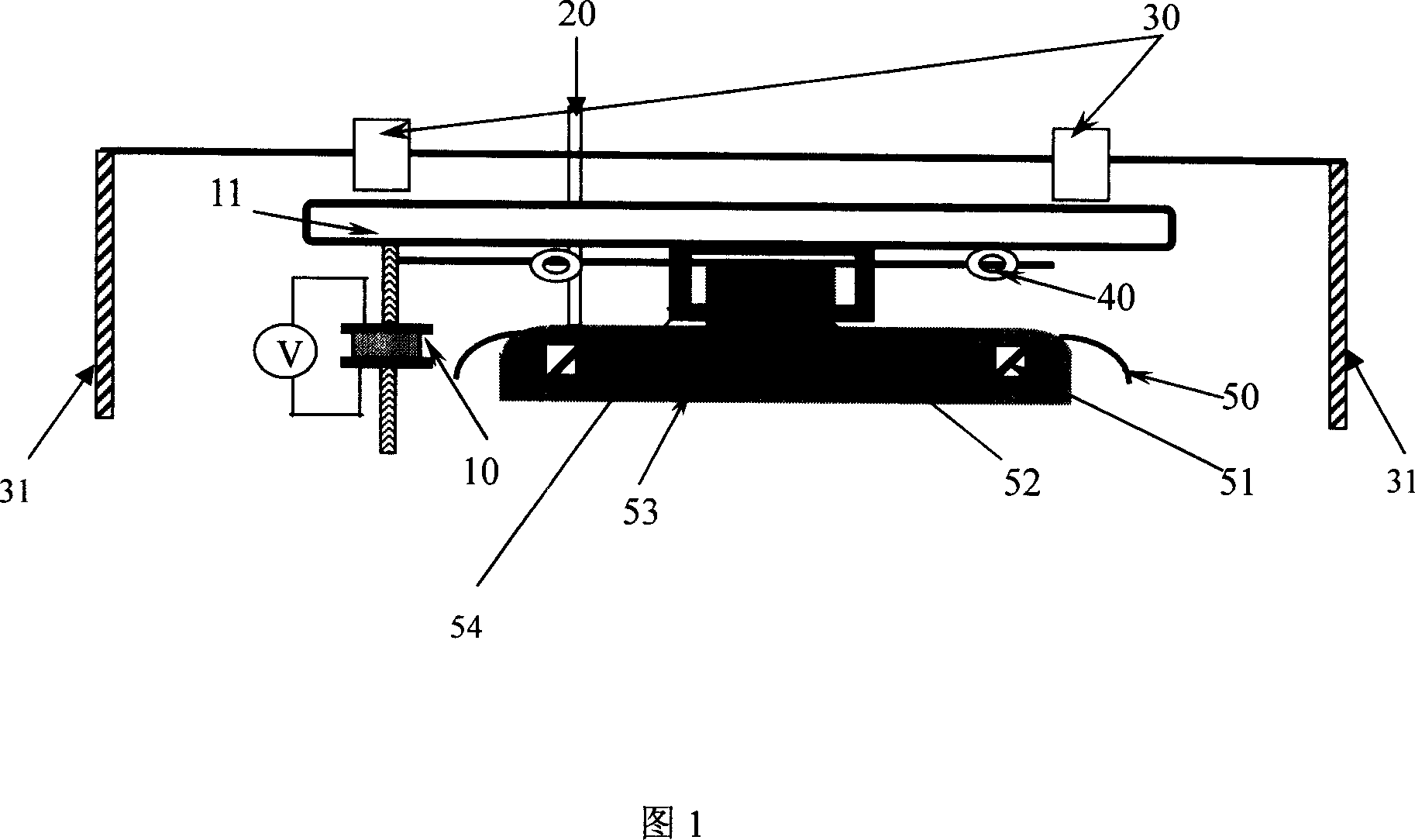

[0027] The optical fiber to be polished is placed on the glass-ceramic for placing the V-shaped grooved fiber, and the positioning reference block glass-ceramic is located at the horizontal position behind the glass-ceramic for placing the V-shaped grooved fiber, which is used to calibrate its relative height. The control motor provides the control voltage of the PZT to adjust the upper and lower positions of the V-groove optical fiber placement glass ceramics. The glass ceramics for grinding and polishing are placed on the grinding block support frame directly above the glass ceramics for placing V-shaped grooved optical fibers. The grinding block support frame is connected to the conveyor belt, and the speed of the conveyor belt is adjusted by controlling the motor to drive the grinding block. Pan in 1D at different speeds. The back-and-forth movement distance of the grinding block is determined by the positioning sensor. The electrode is placed on the slide rail just above ...

Embodiment 2

[0029] The present invention designs a novel optical fiber axial grinding device with a grinding precision as high as 0.01 μm, a grinding length greater than 100 mm, and capable of processing multiple optical fibers simultaneously (Fig. 1).

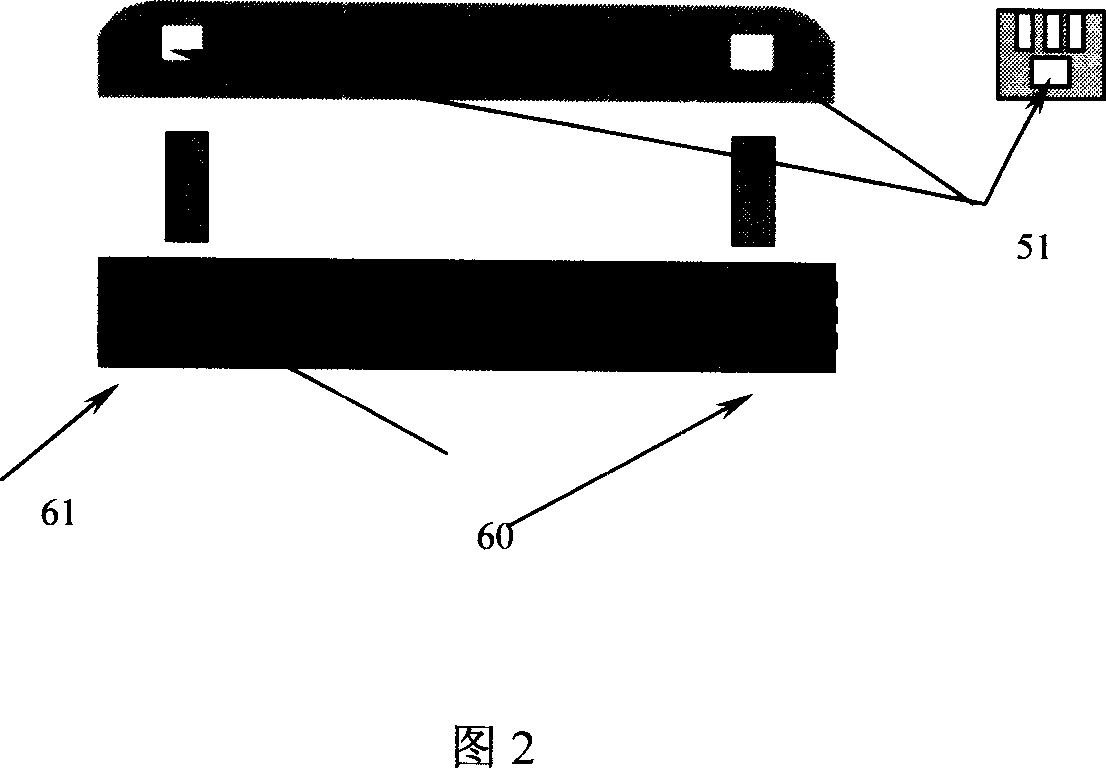

[0030] As shown in Figures 1 and 2, 10 in Figures 1 and 2 is a PZT grinding precision controller, 11 is a conveyor belt whose transmission speed is controlled by a motor, 20 is injecting grinding mud, 30 is a positioning sensor controlled by a relay, and 40 is a positioning sensor Contact points, 50 is the optical fiber to be polished, 51 is the rotatable magnet with knob, 52 is the glass-ceramic grinding block, 53 is the glass-ceramic for V-groove optical fiber placement, 60 is the fixture magnet, 61 is the optical fiber to be polished Use a V-shaped notch.

[0031] The control of optical fiber axial grinding accuracy is the most important parameter of optical fiber axial grinding device. Since the fiber radius is only tens of microns (s...

Embodiment 3

[0041] Embodiment 3: The present invention can achieve grinding accuracy as high as 0.01 μm, grinding length greater than 100 mm, and simultaneous grinding of multiple optical fibers. Select multiple optical fibers to be polished with the same parameters and soak them in acetone solution for about ten minutes, then use wire strippers to remove the coating layer of optical fibers to be polished; use glass ceramics for grinding and polishing with a width greater than the total cross-sectional width of multiple optical fibers to be polished Put it on the grinding frame, then place multiple optical fibers to be polished on the glass-ceramics for placing V-shaped grooved optical fibers, and put the head and tail ends of the optical fibers to be polished into multiple parallel grooves corresponding to both ends, so that Multiple optical fibers to be polished are strictly parallel, hang them with clamps to avoid movement of the optical fibers to be polished, and finally use two small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com