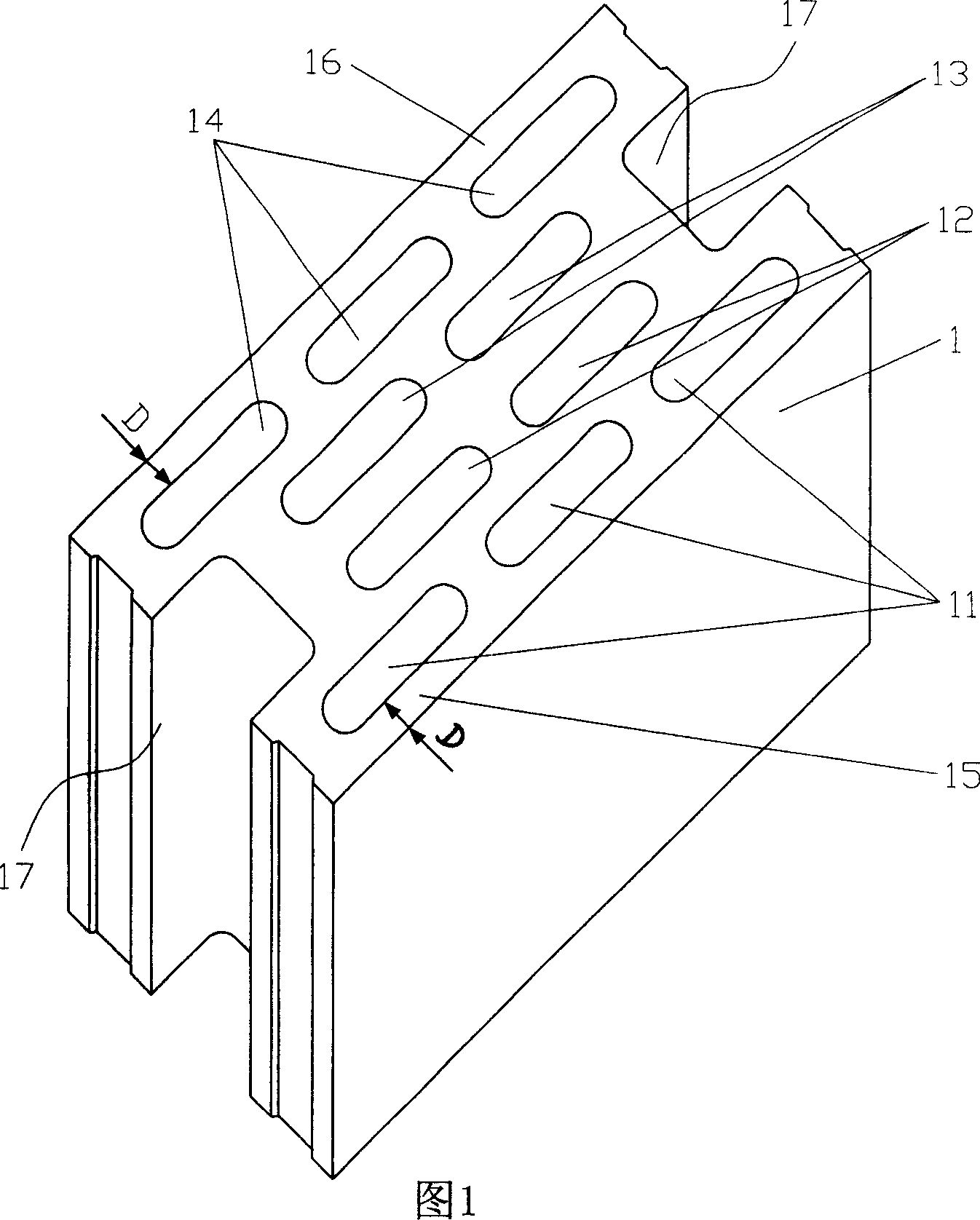

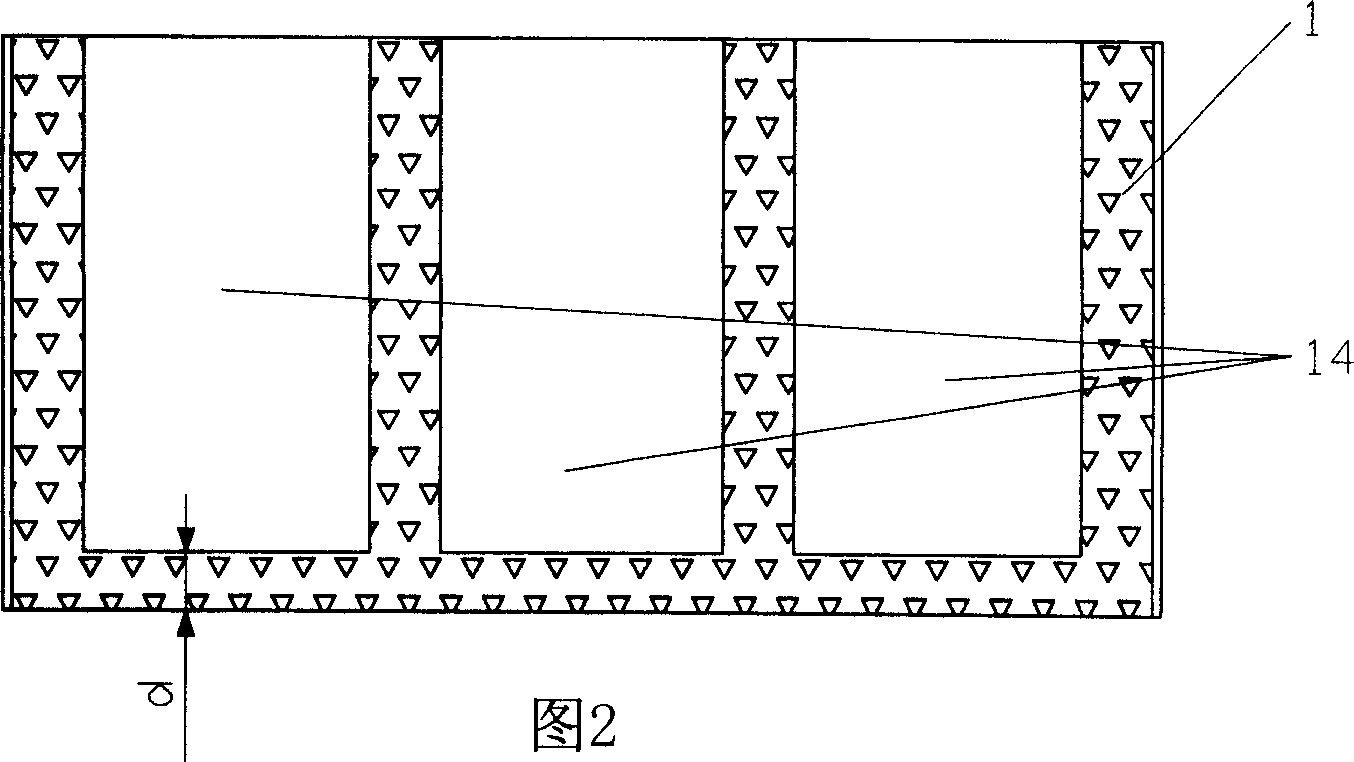

Small hollow flyash block and its making process

A hollow block and fly ash technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of complex composition and structure production process and high manufacturing cost, and achieve weight reduction and sound insulation effect. , the effect of good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] serial number

[0019] After the above batching preparation, the preparation methods of three implementation batching schemes of the hollow block of the present invention are as follows:

[0020] The first step: Put 57-67% of coal ash and 10-15% of cement into the wheel mill;

[0021] Step 2: Add 20-30% of clay ceramsite and 3%-4% of water in the total weight of the mixture, and forcefully stir until uniform;

[0022] Step 3: Put the evenly stirred mixture into the hollow block forming machine, and shape it by high-frequency vibration;

[0023] The fourth step: the formed hollow block is covered with a film, and it is closed and stagnant for 24 hours;

[0024] Step 5: Place the closed and stagnant hollow block into a steam curing kiln for 8 hours to complete the finished hollow block.

[0025] The present invention adopts the above-mentioned three kinds of batching implementations and the hollow block manufactured by the preparation method, as shown in Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com