Prepn process of transparent toughened magnesia alumina spinel ceramic

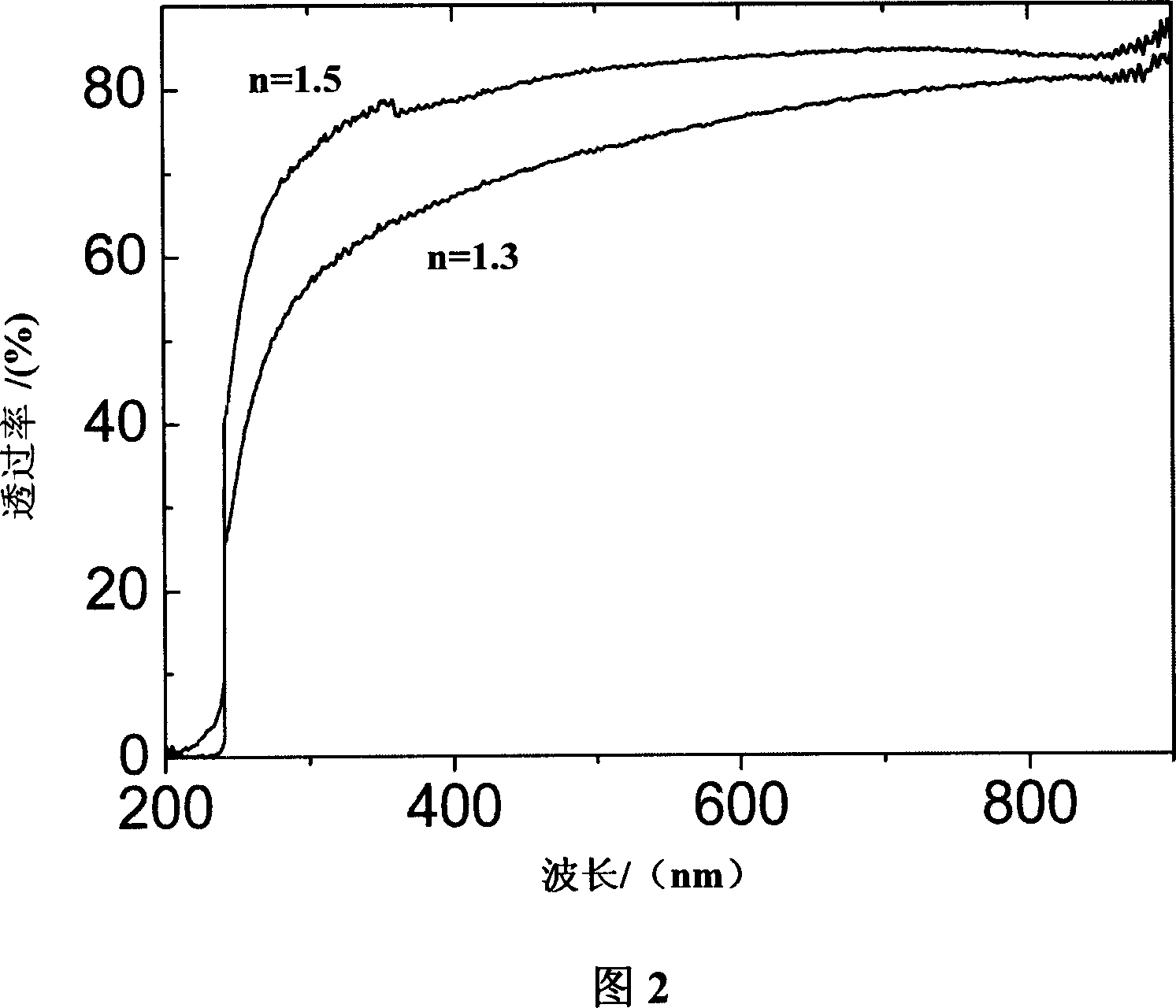

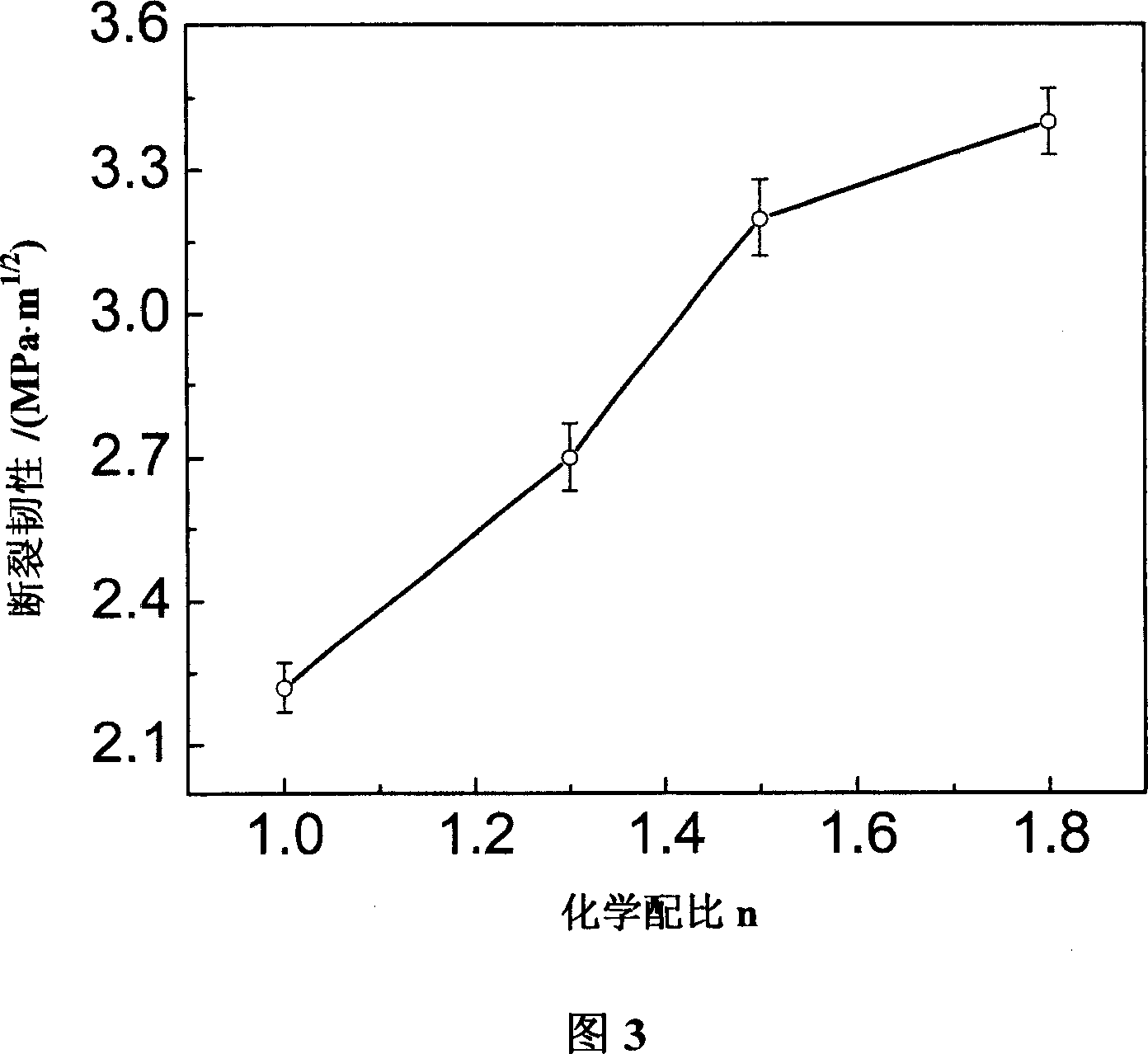

A technology of tough magnesium aluminum spinel and magnesium aluminum spinel, which is applied in the field of transparent ceramic preparation to achieve the effect of simple preparation process, tight combination and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The processing steps of the present embodiment are as follows:

[0034] (1) Powder preparation and granulation

[0035] Weigh 1000.00 grams of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 12H 2 O, analytical purity ≥99.99%) and 208.86 grams of magnesium sulfate (MgSO 4 ·7H 2 O, analytical purity ≥ 99.99%), put it into a wide-mouthed quartz cup, add deionized water (the addition of deionized water is not strictly required, and flood the MgSO 4 ·7H 2 O and NH 4 Al(SO 4 ) 2 12H 2 O can be), fully stirred until completely dissolved; put the quartz cup with the mixed solution into the muffle furnace for roasting, heat to 1100 °C at a heating rate of 10 °C / min, and roast at this temperature for 6 hours to complete the formation of spinels Then, it is cooled to room temperature with the furnace, sieved with a 250-mesh sieve after grinding, and the magnesium-aluminum spinel nano-powder of about 30nm is obtained;

[0036] The sieved magnesium aluminum spinel nanopowde...

Embodiment 2

[0044] The processing steps of the present embodiment are as follows:

[0045] (1) Powder preparation and granulation

[0046] Weigh 1000.00 grams of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 12H 2 O, analytical purity ≥99.99%) and 181.01 grams of magnesium sulfate (MgSO 4 ·7H 2 O, analytical purity ≥ 99.99%), put it into a wide-mouthed quartz cup, add deionized water (the addition of deionized water is not strictly required, and flood the MgSO 4 ·7H 2 O and NH 4 Al(SO 4 ) 2 12H 2 O can be), fully stirred until completely dissolved; put the quartz cup with the mixed solution into the muffle furnace for roasting, heat to 1150 °C at a heating rate of 5 °C / min, and roast at this temperature for 4 hours to complete the formation of spinels Then, it is cooled to room temperature with the furnace, sieved with a 250-mesh sieve after grinding, and the magnesium-aluminum spinel nano-powder of about 30nm is obtained;

[0047] The sieved magnesium aluminum spinel nanopowder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com