Low-temperature film pressure sensor and producing method thereof

A film pressure and production method technology, applied in the measurement of fluid pressure, elastic deformation meter type fluid pressure measurement, fluid pressure measurement by changing ohmic resistance, etc., can solve problems such as large measurement error, achieve a wide range of applications, The effect of improving the accuracy and improving the accuracy of zero point compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

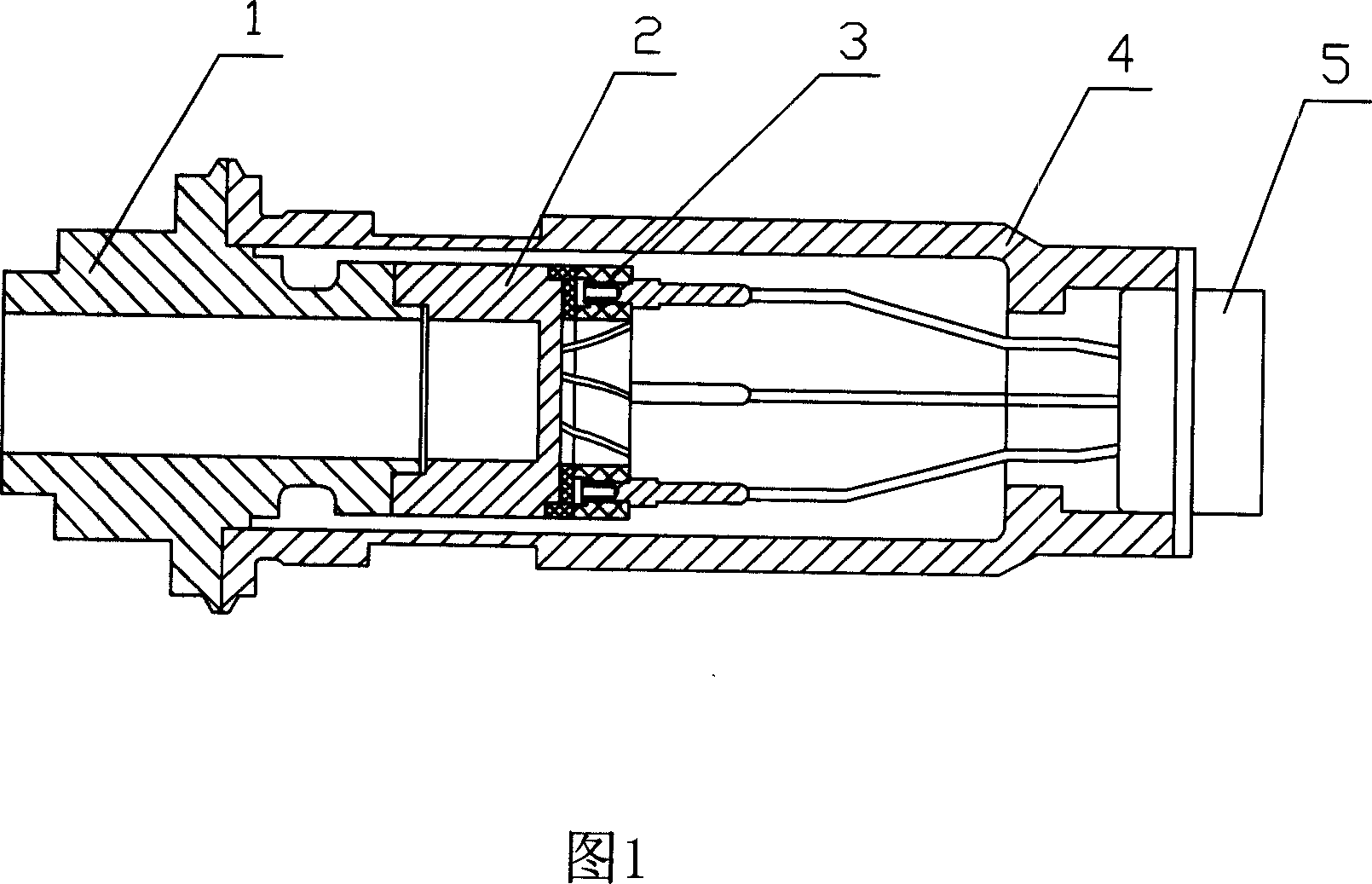

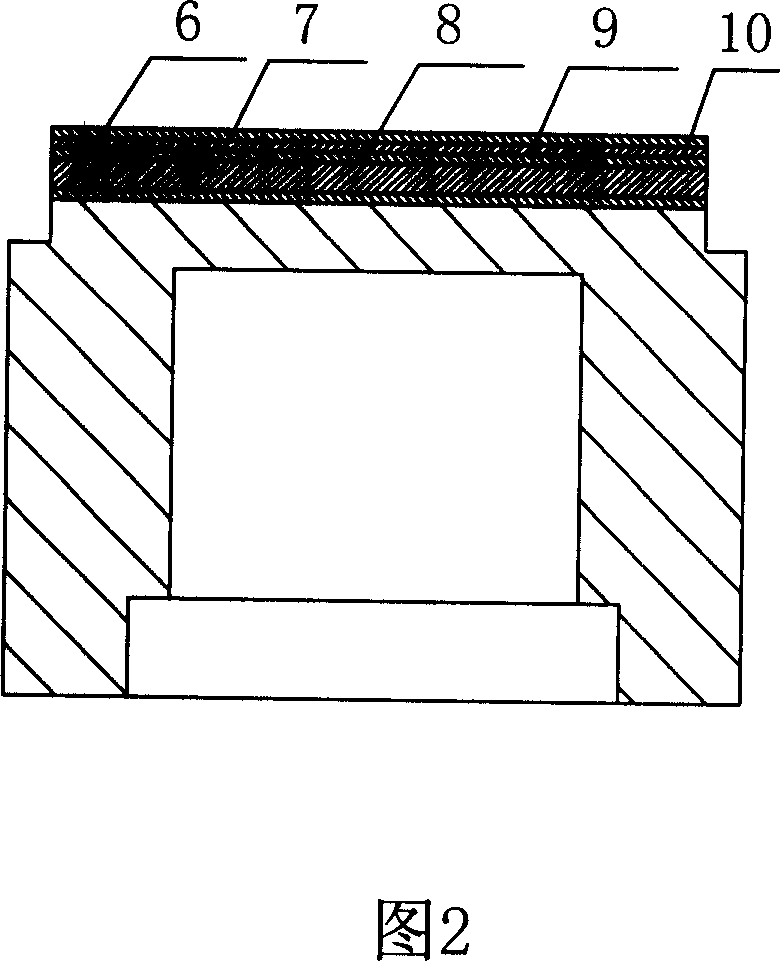

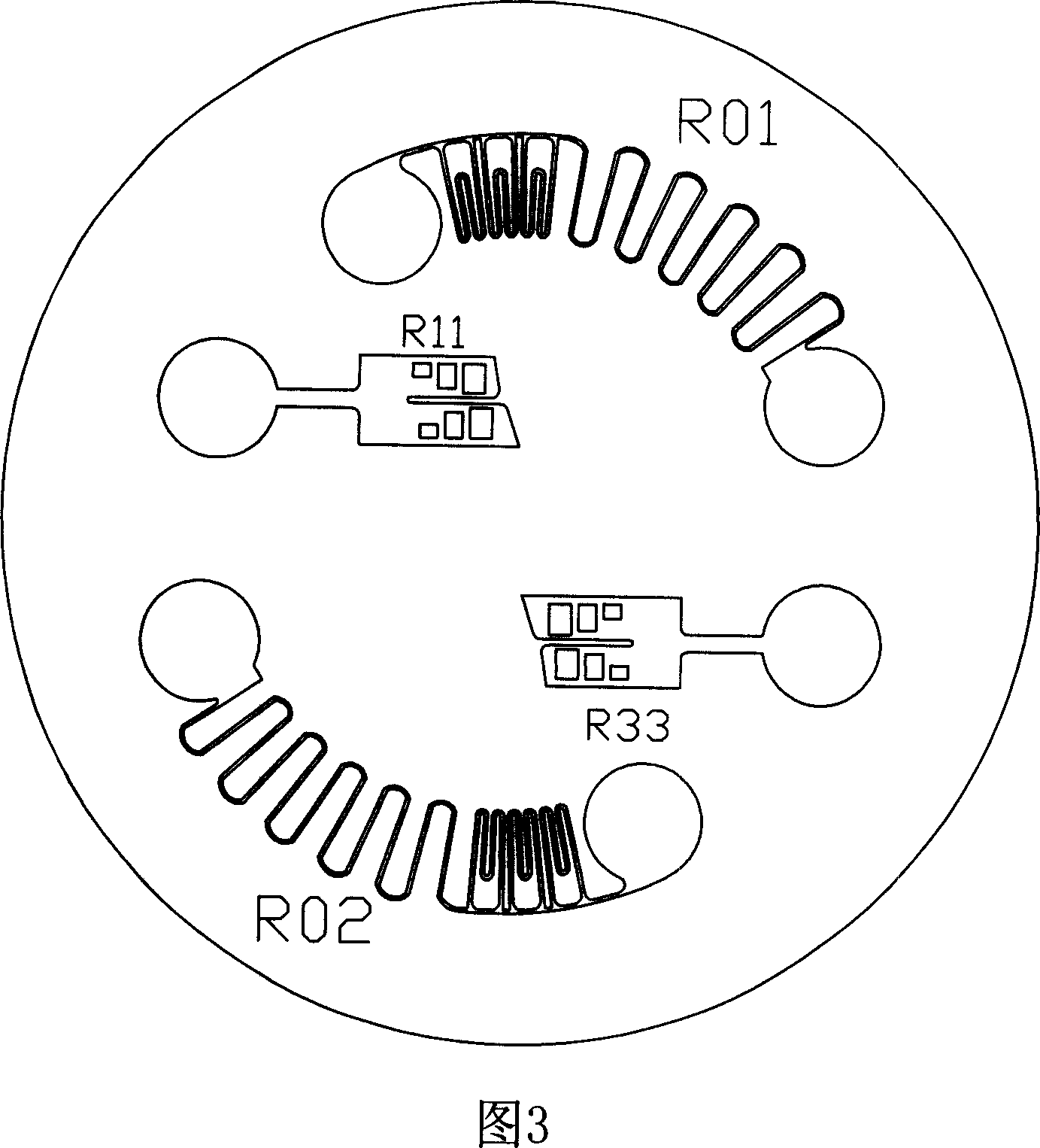

[0037] The low-temperature thin-film pressure sensor of the present invention is shown in FIG. 1 , and is composed of a nozzle 1 , a diaphragm assembly 2 , an adapter seat 3 , a housing 4 , and a socket 5 . The diaphragm assembly 2 includes a diaphragm 21 and a thin film 22 arranged on the diaphragm 21. The thin film 22 is sequentially deposited from the inside to the outside by ion beam sputtering to form a transition layer 6, an insulating layer 7, a strain resistance layer 8, and a compensation resistance layer 9 And the pad layer 10, the diaphragm assembly 2 is stabilized, and one end is bonded to the adapter seat 3, and the other end is welded to the nozzle 1, and the nozzle 1 and the housing 4 are welded, so that the diaphragm assembly 2 is arranged on the housing 4 Inside, the socket 5 is fixedly connected to the housing 4 with screws. The connection of the electrical signal is: the Au pad on the film 22 is connected to the electrical connection pin of the adapter seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com