Coal slagging scorification trend fast monitoring instrument

A monitor and slagging technology, applied in the field of coal combustion, can solve the problems of poor measurement result accuracy, large workload, cumbersome steps, etc., and achieve the effect of convenient industrial installation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

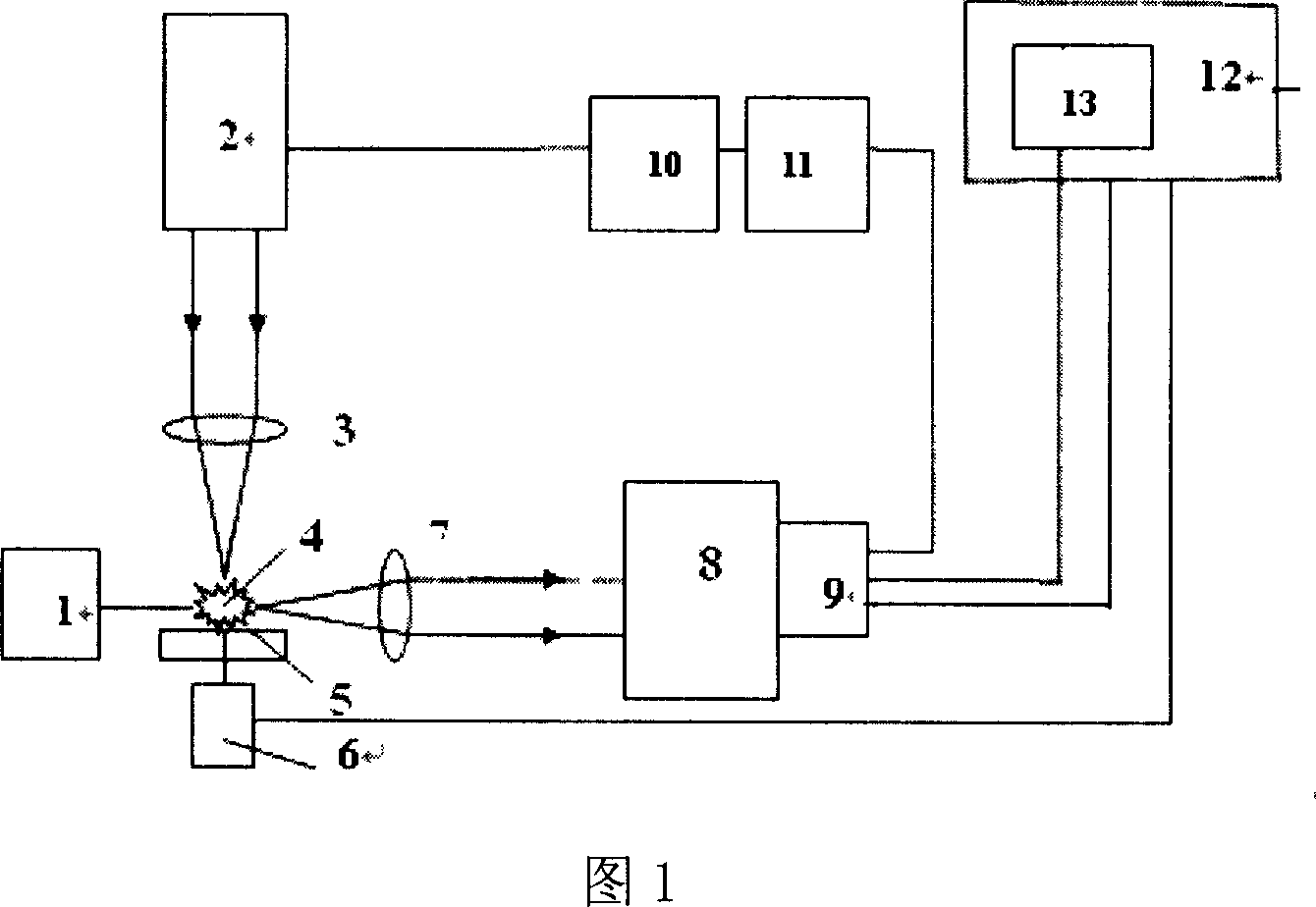

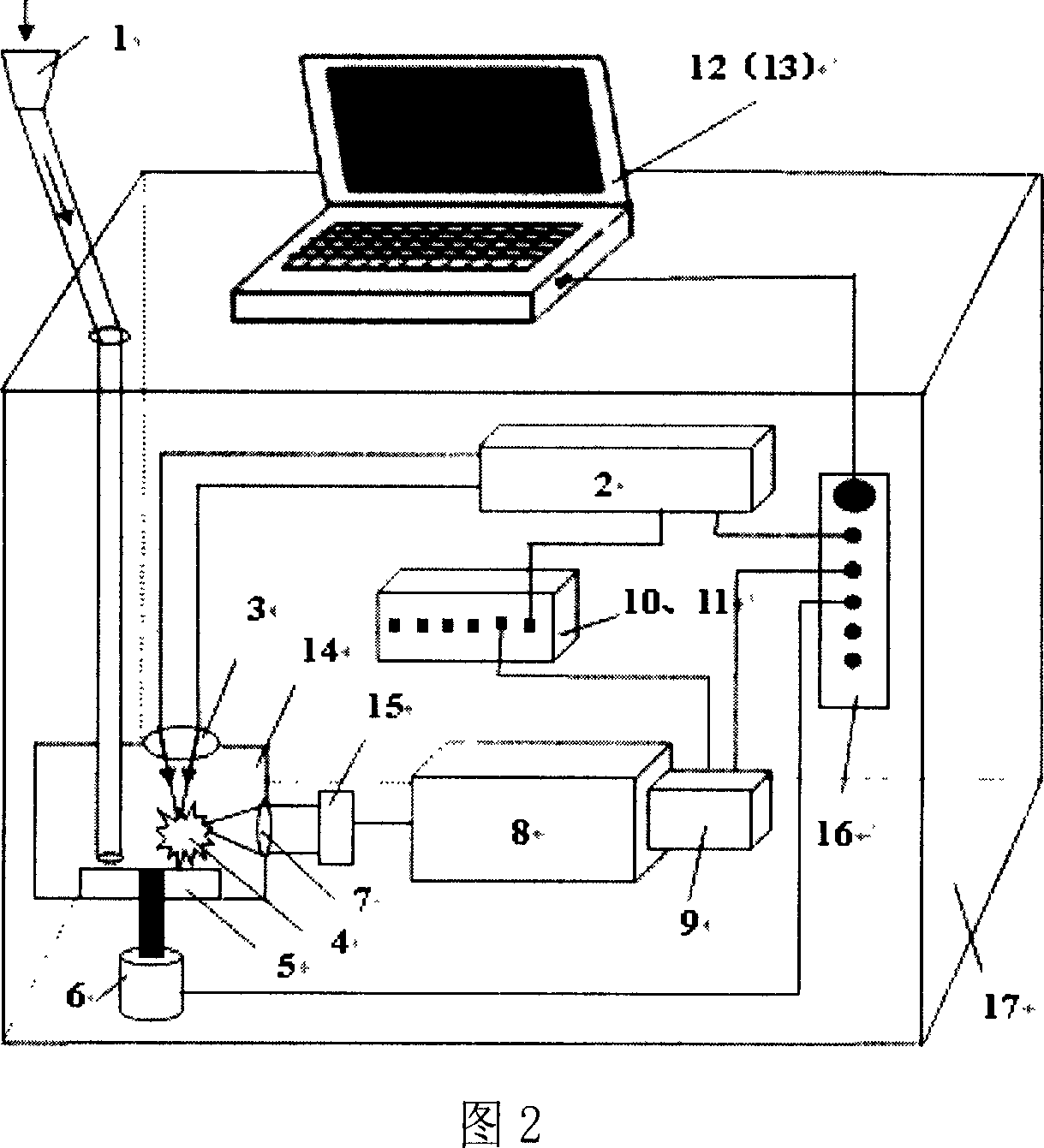

[0022] As shown in Figures 1 and 2, the structural body of the monitor of the present invention is divided into three parts, one part is a sampling part, the second part is a detection part, and the third part is an analysis part. Wherein, the sampling part includes a sampling system 1 and a sample analysis pool 14, the detection part includes a trigger laser light source 2, a spectroscopic system 8, a detector 9, a pulse generator 10 and a time delay device 11, and the analysis part includes a data analysis module 13, and the data analysis The modules are implemented by software systems in the computer 12 . Among them, the first part and the second part are installed on site, and the third part can be installed in the control room, so that the operator can get real-time data without working in a harsh environ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com