Meso-porous material containing nano silver granulates and preparing method

A technology of nano-silver particles and mesoporous materials, applied in the field of mesoporous materials and their preparation, can solve the problems of toxic use conditions, harsh conditions, and easy to be buried in the pore wall, avoiding the use of organic reagents, and achieving uniform particle size. , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of Mesoporous Materials Containing Nano-Silver Particles Using SBA-15 as a Carrier

[0022] a. Take 1000 mg of SBA-15 sample, put it into a quartz tube furnace, and first purging it with nitrogen for 30 minutes at a flow rate of 80ml / min, then injecting ammonia gas at a flow rate of 100ml / min, while raising the temperature to 1000°C for 20 Hour. It was then cooled to room temperature under a nitrogen atmosphere. The nitrided product SBA-15N1 was obtained with a nitrogen content of 10%.

[0023] b. Take 100 mg of the nitriding sample SBA-15N1 prepared in a above, put it into a small crucible, and then put it into a container. Use a dropper to add silver nitrate solution to the crucible until the sample is just completely wet. Put it in the ultrasonic pool for ultrasonic treatment for 30-120 minutes, take it out and dry it.

[0024] c. Put the dried sample into a muffle furnace, raise the temperature to 300° C., and keep it for 3 hours to finally obtain the...

Embodiment 2

[0026] The sample Ag-SBA-15N1 that obtains in embodiment one is carried out each property test, and test situation and result thereof are as follows:

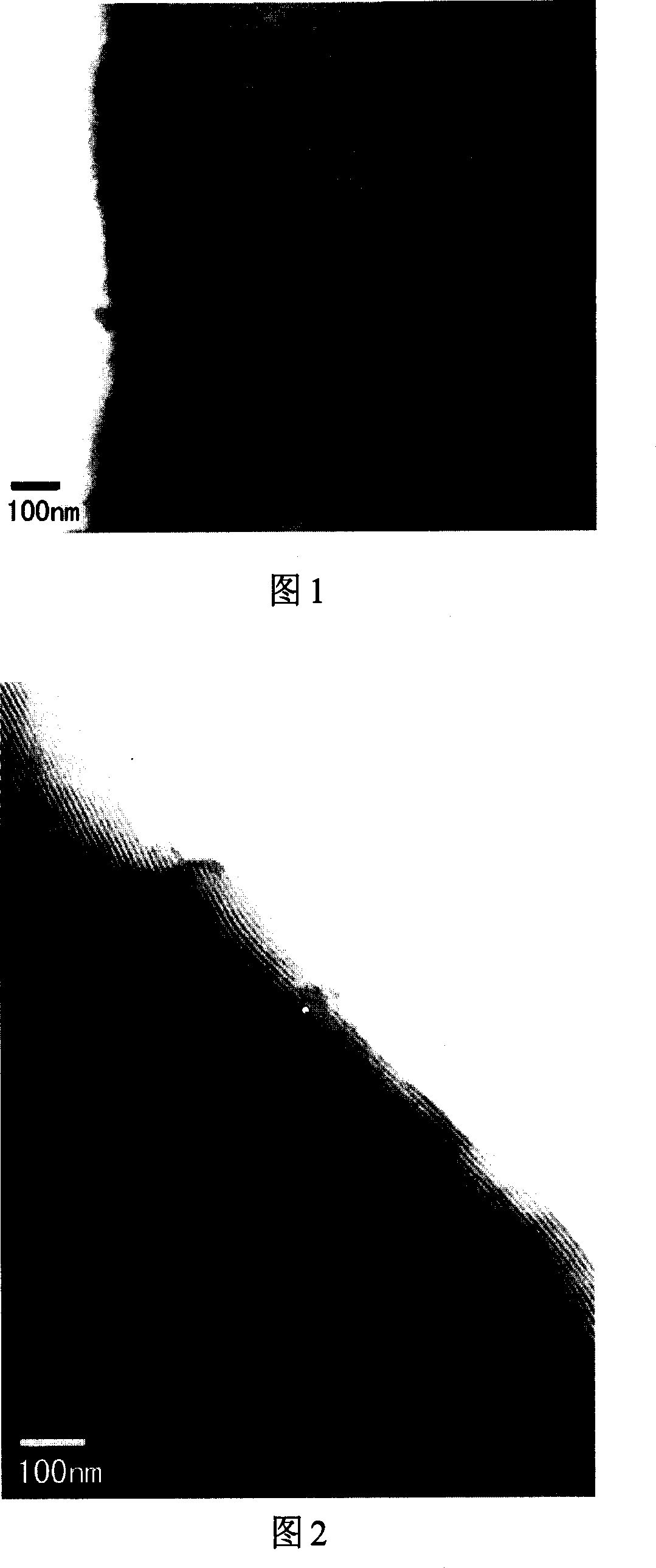

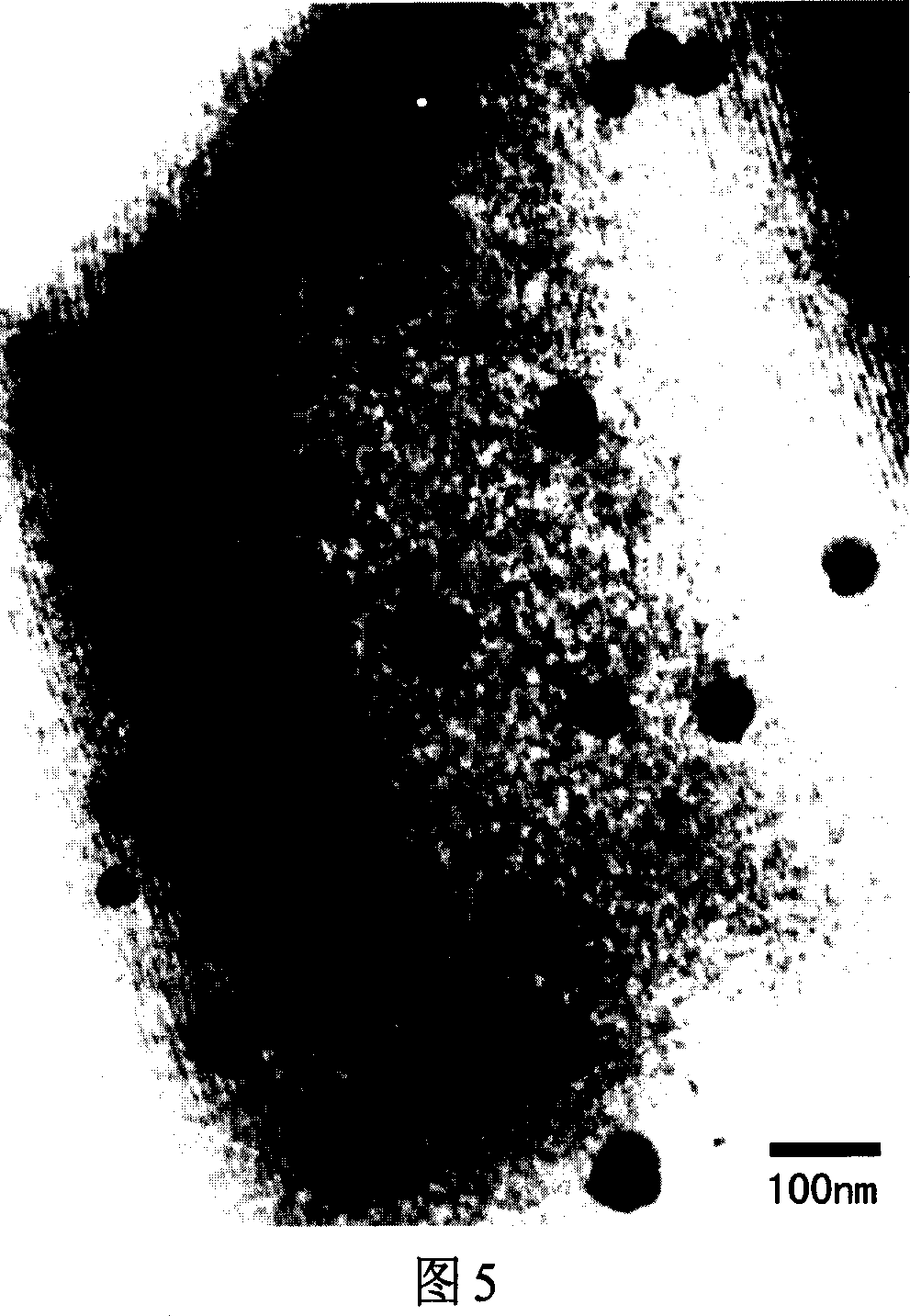

[0027] Using a transmission electron microscope (TEM) to observe, it can be seen that there are nano-silver particles in the pores of the mesoporous molecular sieve, the shape is spherical or ellipsoidal, the particle size is uniform, and the particle size is 7-8 nanometers. Under the same field of view, the number of silver particles on the outer surface is less than 5% (such as figure 1 and figure 2 shown).

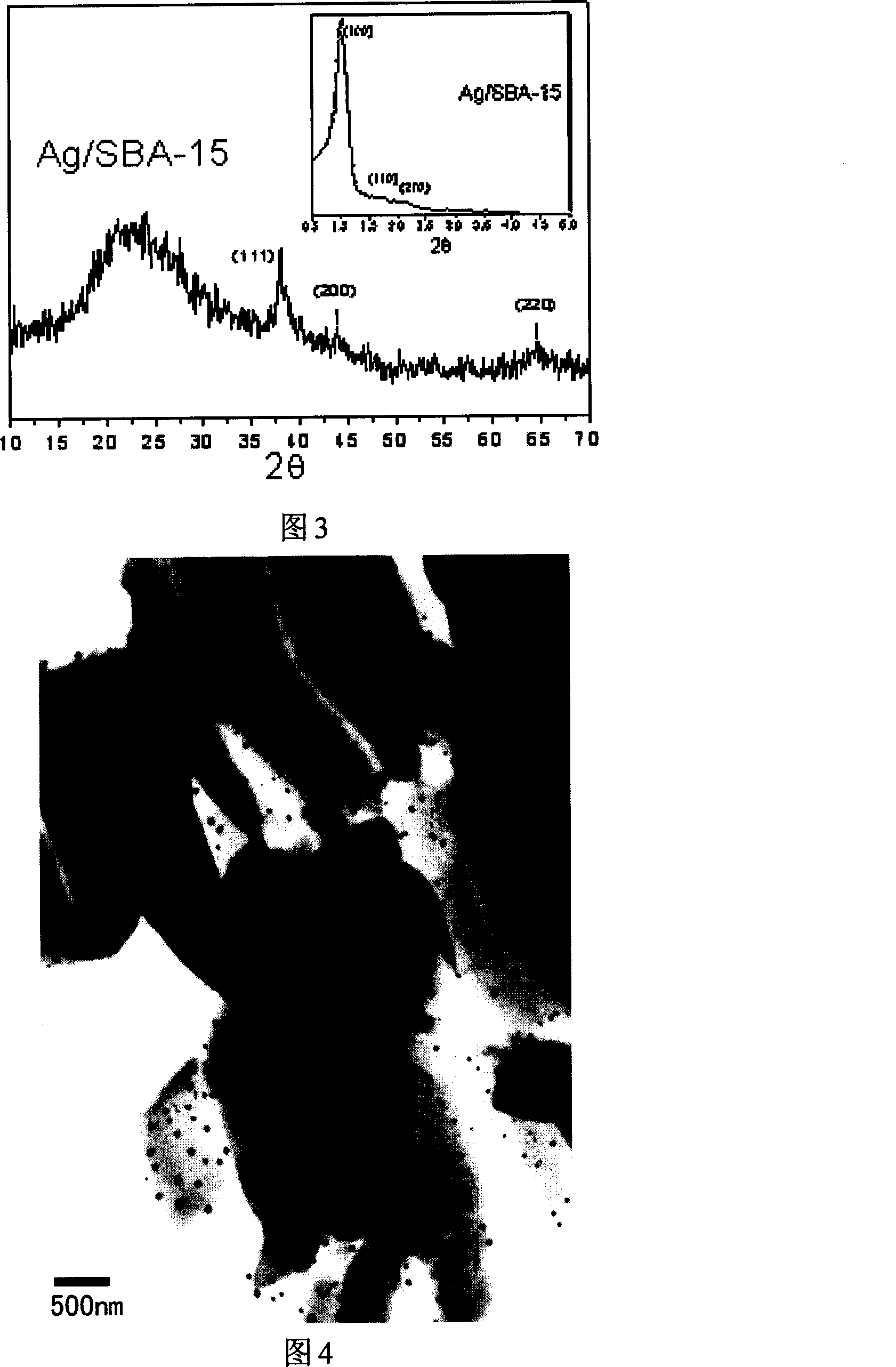

[0028] Using X-ray diffraction analysis (XRD), it can be determined from the diffraction peak that the regular pore structure of the mesoporous material is maintained, and the presence of crystalline silver particles (such as image 3 ).

Embodiment 3

[0030] Preparation of Mesoporous Materials Containing Nano-Silver Particles Using SBA-15 as a Carrier

[0031] a. Take 1000 mg of SBA-15 sample, put it into a quartz tube furnace, and first blow it with nitrogen for 30 minutes at a flow rate of 80ml / min, then introduce ammonia gas at a flow rate of 15ml / min, and simultaneously raise the temperature to 1000°C and keep for 40 Hour. It was then cooled to room temperature under a nitrogen atmosphere. A nitrided mesoporous material SBA-15N2 with a nitrogen content of 15% was obtained.

[0032] b. Take 100 mg of the nitriding sample SBA-15N2 prepared in a above, put it into a small crucible, and then use a dropper to drop the silver nitrate solution into the crucible until the sample is just completely wetted. Put the crucible in a water bath and heat it to 50-80°C, keep it for 5-10 hours, then take it out and dry it.

[0033] c. Put the dried sample into a muffle furnace, raise the temperature to 300°C, and keep it for 6 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com