Perforating structural component for cast-in-situs reinforcing-bar concrete

A reinforced concrete and hole-forming technology is applied in building components, on-site preparation of building components, building construction, etc., and can solve problems such as high cost, troublesome hollow tube production, and increased hollow floor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

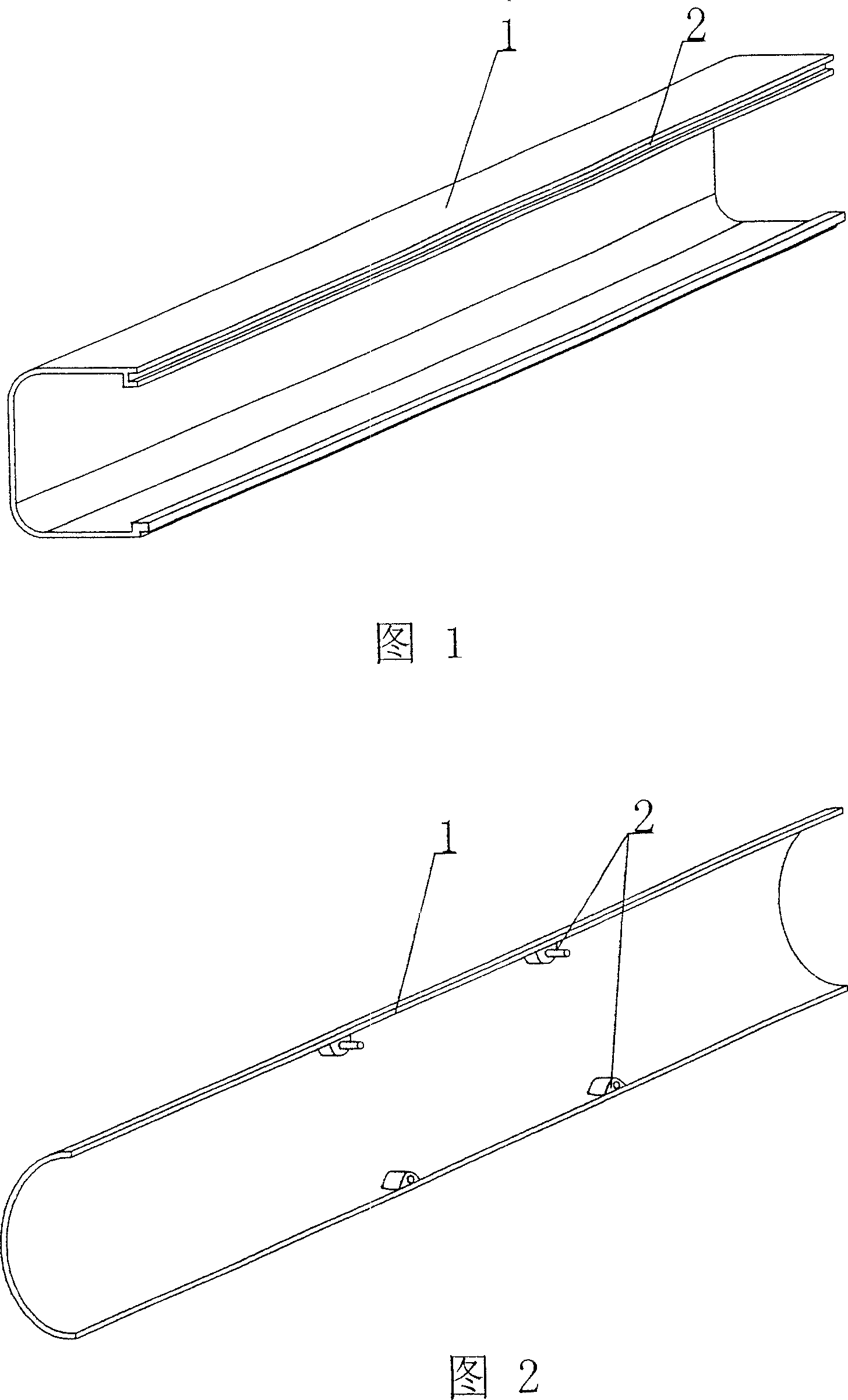

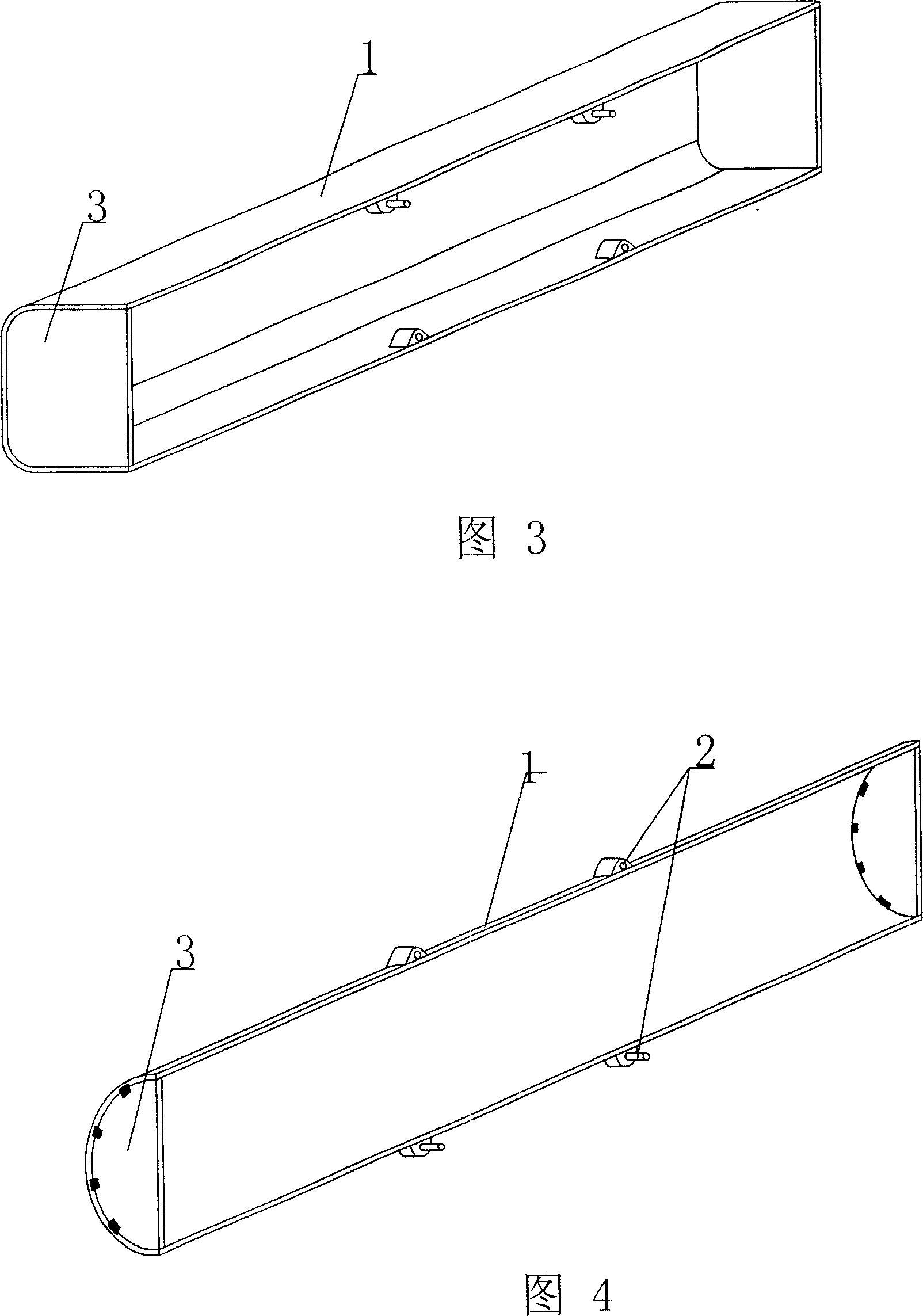

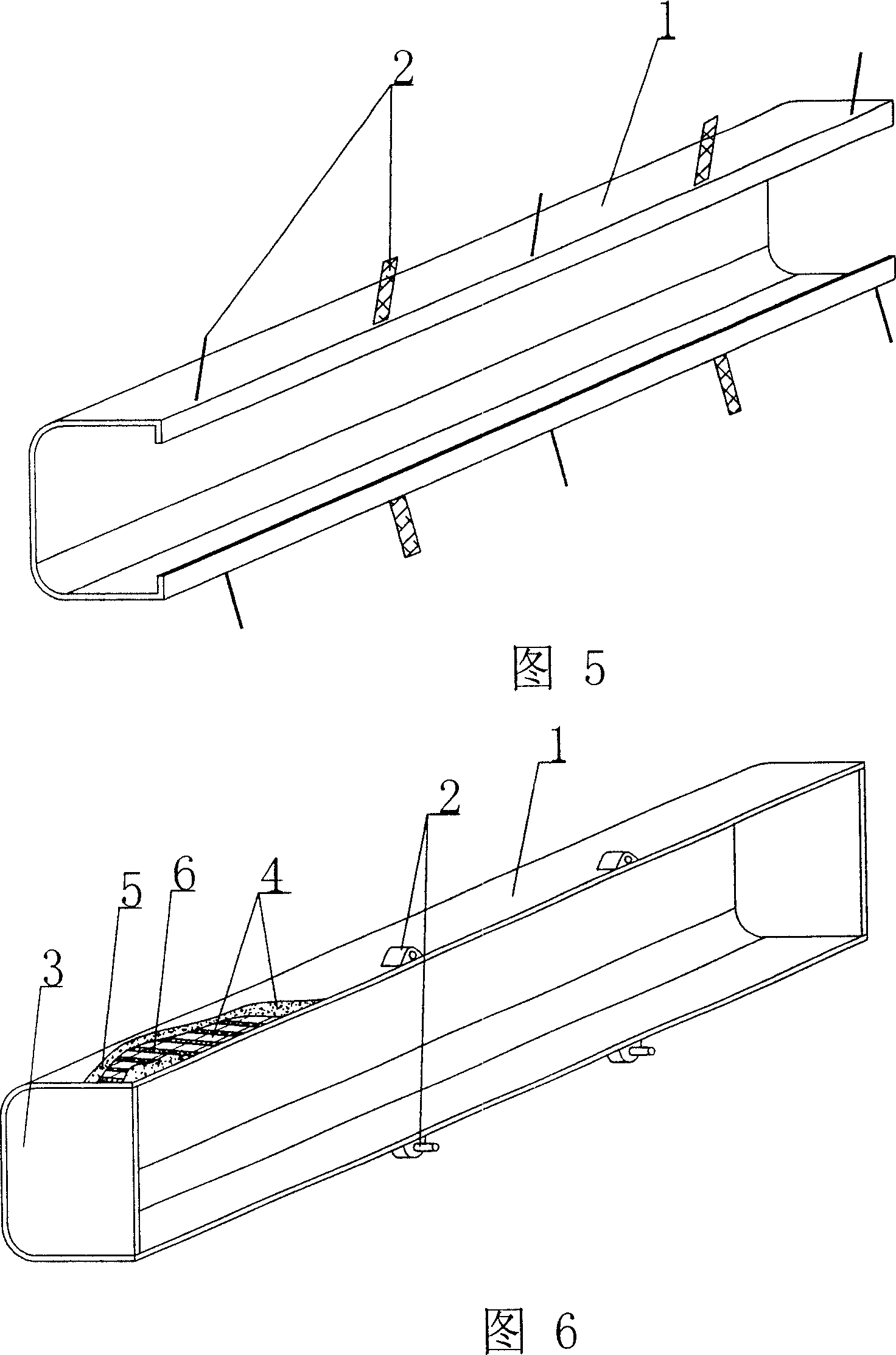

[0042] The present invention, as shown in the accompanying drawings, is characterized in that the hole-forming member is a combination part 1 that constitutes an integral member of the cavity, the combination part 1 is provided with a connecting piece 2 for combination, and the two ends of the combination part 1 are provided with The end plate 3 constitutes a basin-shaped composite part, and the hole-forming member is formed by buckling two basin-shaped composite parts at the mouth of the basin. set up. In the accompanying drawings, 1 is an assembly part, and 2 is a connecting piece. In each accompanying drawing, those with the same number have the same description. As shown in Figure 1, the hole-forming member is a combination part 1 that constitutes a combined cavity-forming integral part, on which are provided joints 2 for combination, shown as a ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com