Dual-damascene process

A dual damascene process and process technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult removal of metallized polymers, contact hole offset, etc., to achieve a wide operating tolerance, reduce the key Size, simple effect of dual damascene process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

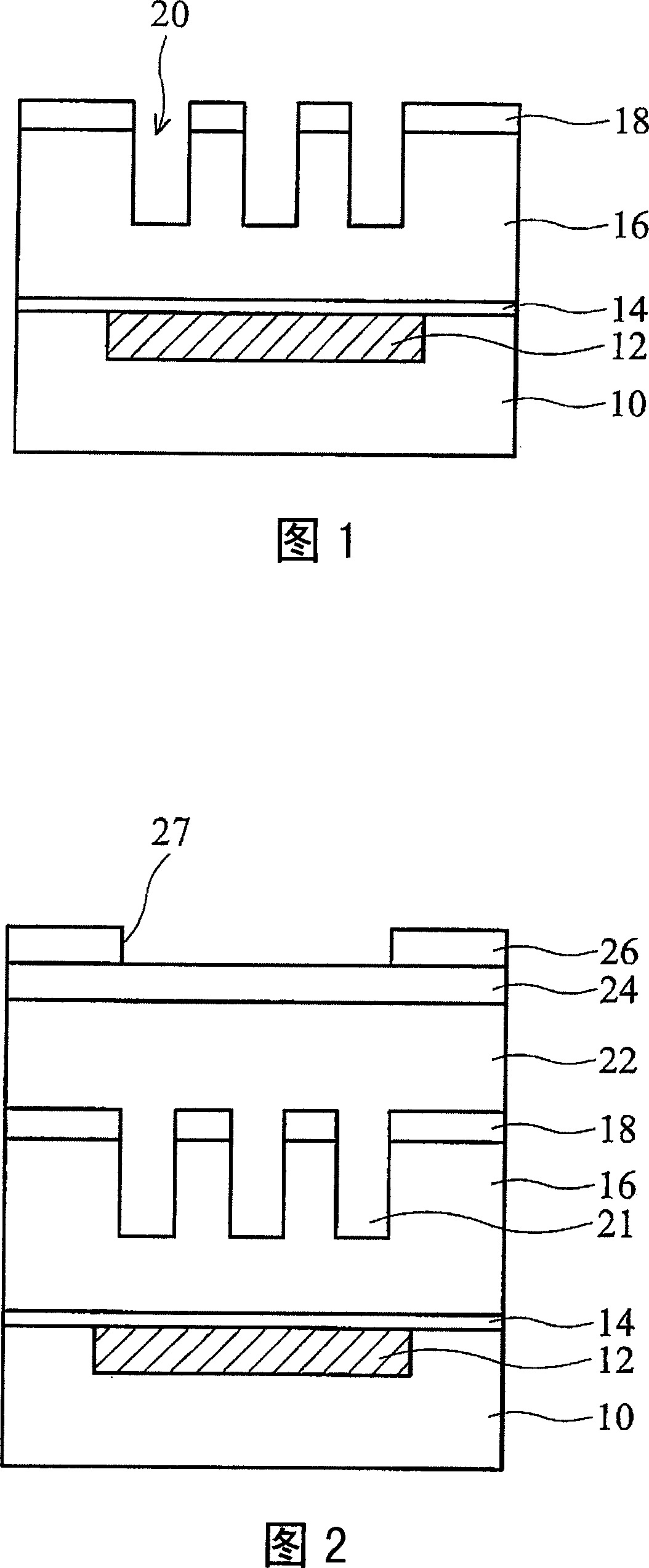

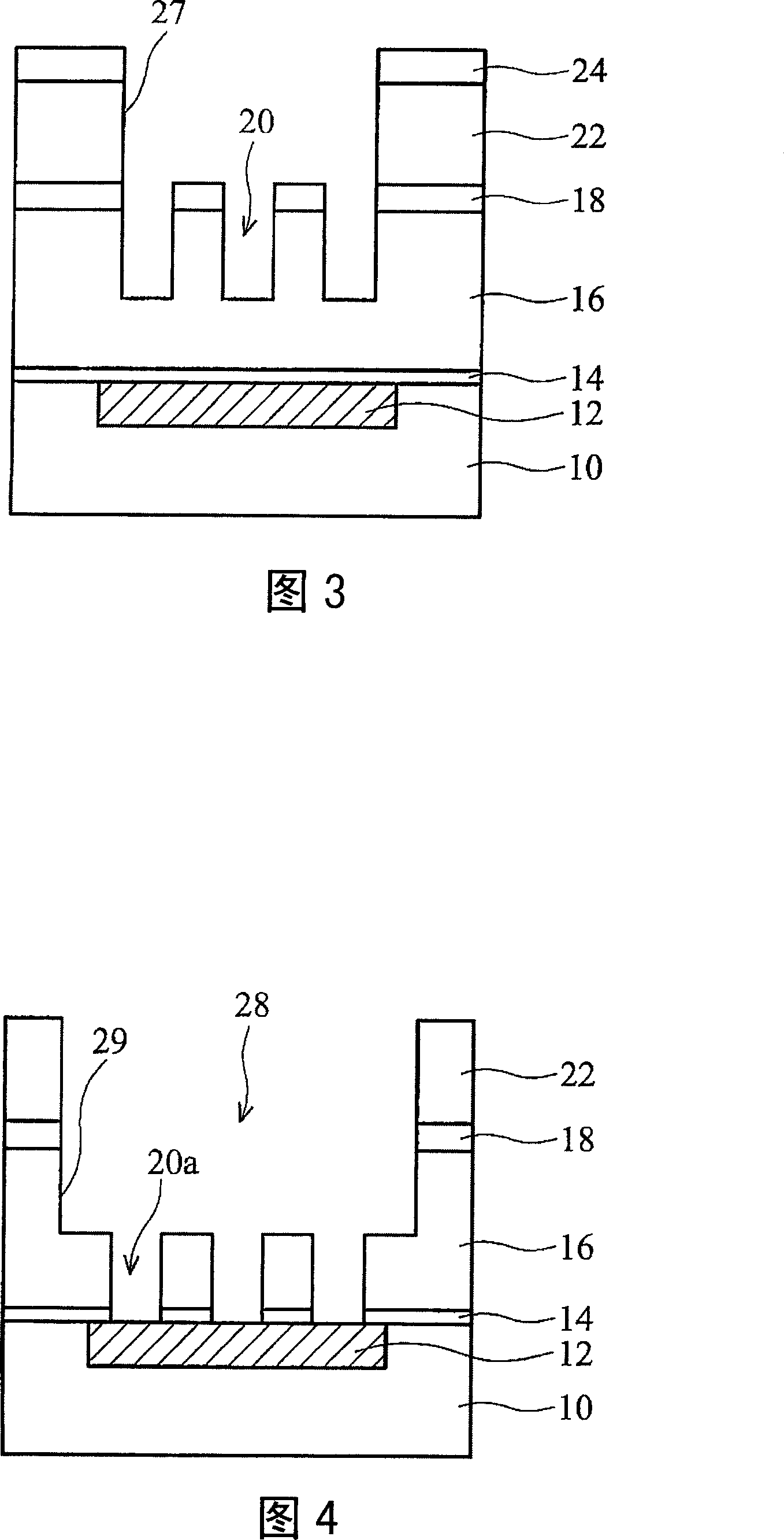

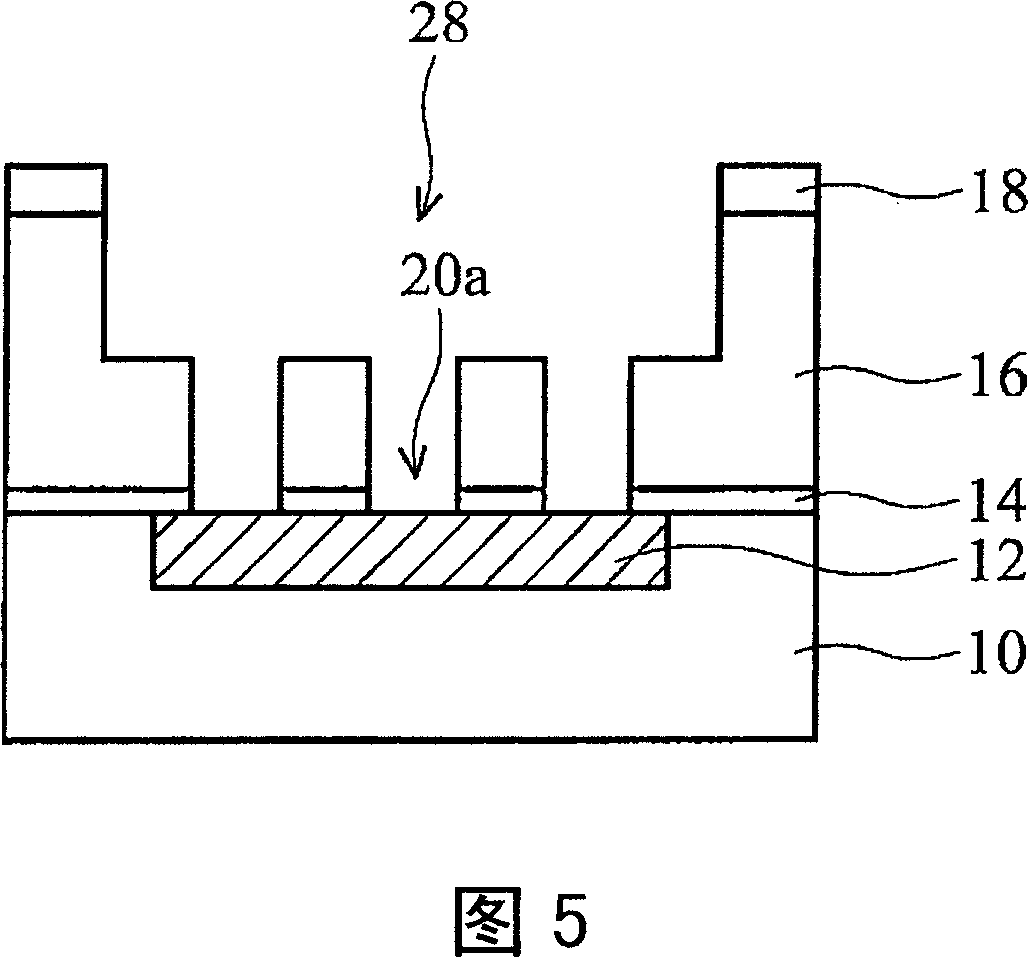

[0016] The present invention provides a double damascene process, which can overcome the problems existing in the application of three-layer impedance and metal mask processes in the prior art. In particular, the present invention applies a dual damascene process with partial contact hole priority of three-layer impedance, which can avoid ashing damage and improve the critical dimensions of trenches and contact holes, and can make the contact hole without increasing the process and cost. The wet stripping step has a wider operating tolerance. Compared with the well-known "full contact hole first" process, "partial contact hole first" means that the contact hole formed at the beginning only penetrates part of the thickness of the dielectric layer, and then the contact hole is formed in the lower half of the dielectric layer , and form trenches in the upper half of the dielectric layer.

[0017] In the following description, the same symbols are used as much as possible to desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com