MOS field effect pipe and its production

A technology of field effect transistors and low-voltage transistors, which is applied in the field of MOS field effect transistors and its production, and can solve problems such as transistor threshold voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

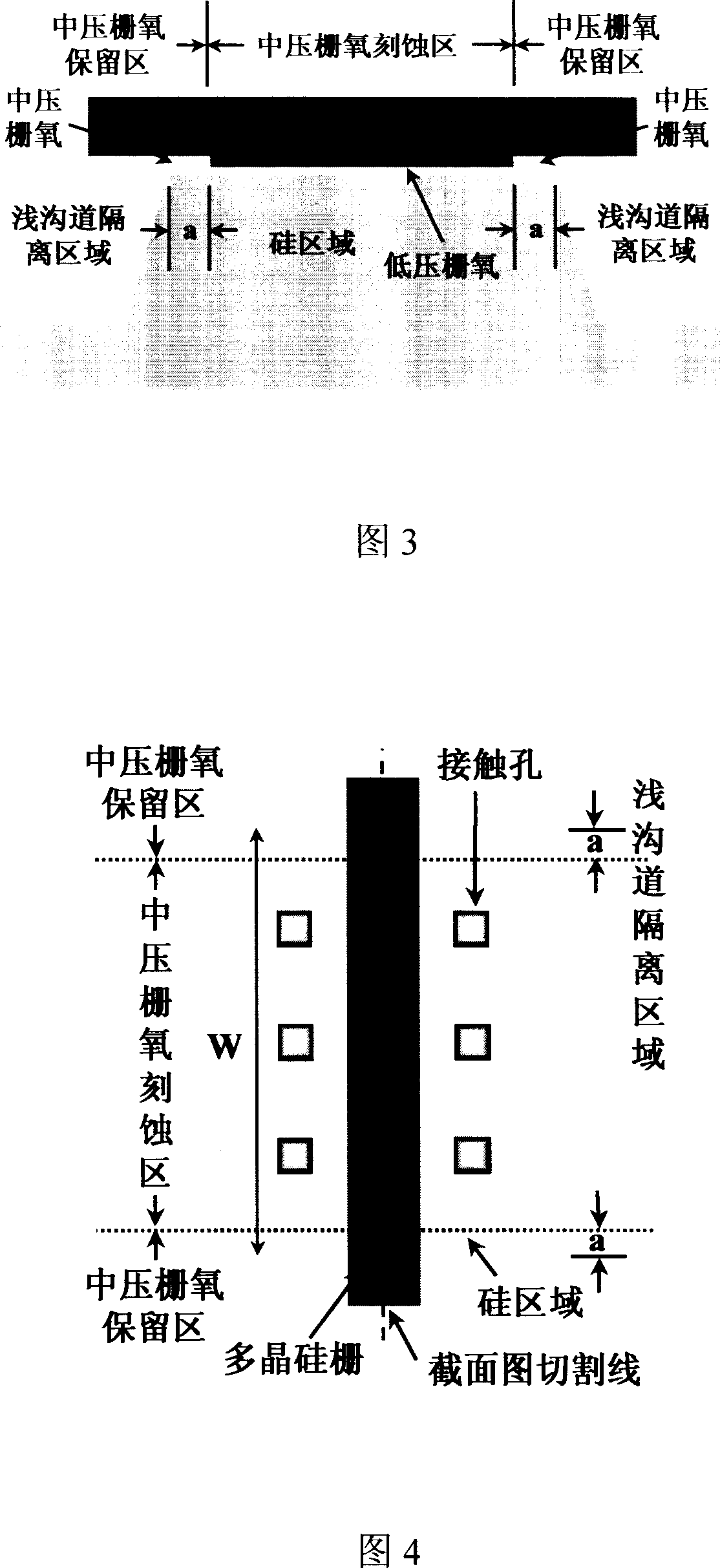

[0013] Fig. 3 is a schematic diagram of the cross-sectional structure of the MOS field effect transistor of the present invention. As shown in FIG. 3 , the MOS field effect transistor of the present invention has shallow trench isolation regions on both sides of the silicon region, a gate oxide on the top, and a polysilicon gate on the top of the gate oxide. Since the medium-voltage gate oxide in the middle of the silicon region is etched during the double gate oxide etching step, only the low-voltage gate oxide exists in the middle of the silicon region. And in the silicon region near the junction of the shallow trench isolation region and the silicon region, the distance from the junction of the shallow trench isolation region and the silicon region is a to the place of the junction, in the double gate oxide etching step The medium-voltage gate oxide is not etched, so that this part of gate oxide includes low-voltage gate oxide and medium-voltage gate oxide. Therefore, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com