Full sleeve large diameter vibration soil taking and filling pile construction method

A construction method and large-diameter technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing pile bottom reaction force and side wall friction, reducing pile foundation bearing capacity, and high construction costs. Achieve the effects of increasing the ability to penetrate the foundation soil, reducing frictional resistance, and facilitating construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

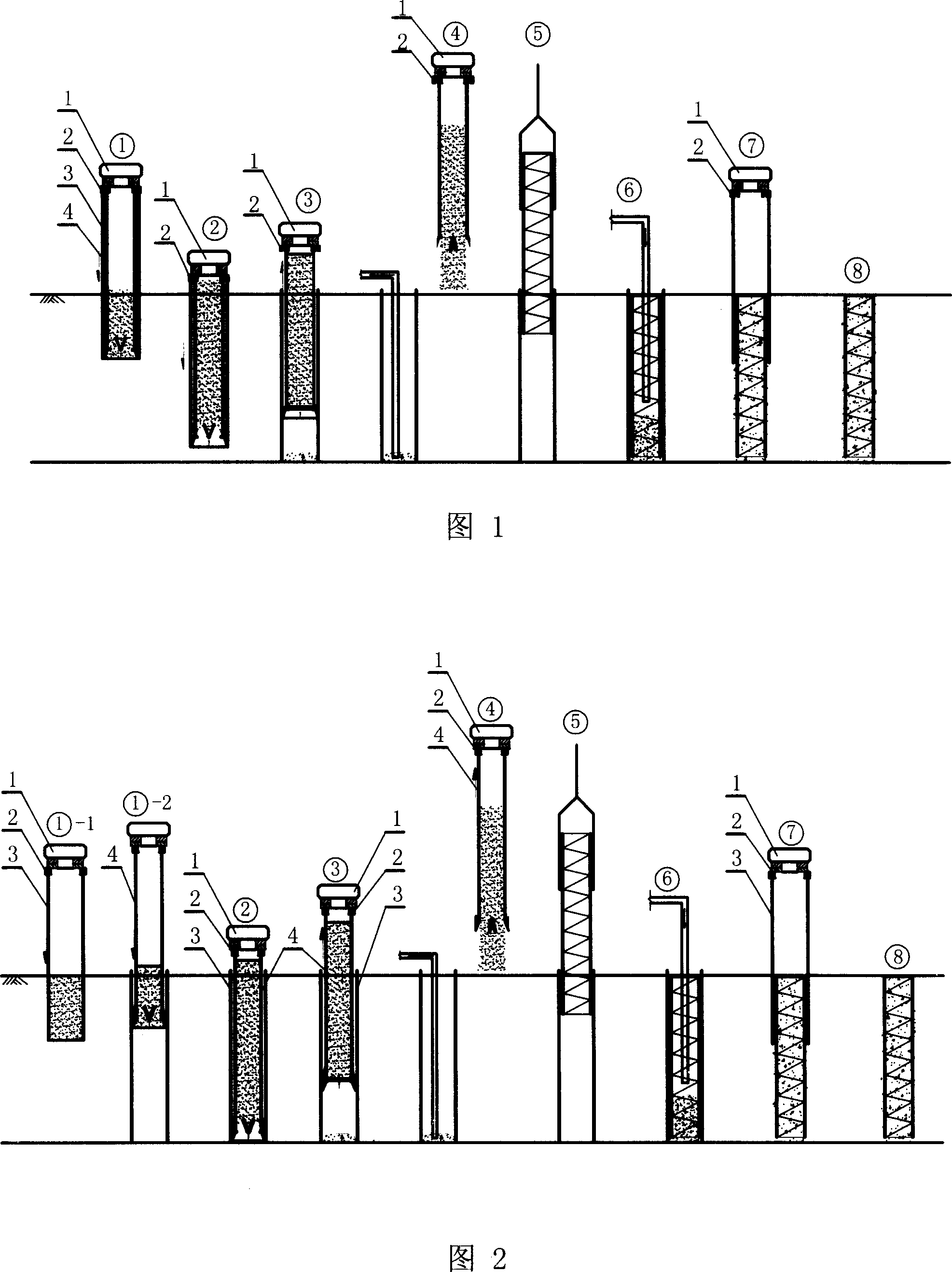

Embodiment 1

[0030] Embodiment 1: The construction method of the large-diameter vibrating soil-borrowing cast-in-place pile with full sleeve pipe of the present invention includes two processes of hole forming and concrete pouring. The inner and outer casings in the hole forming process are soil-borrowing and hole-forming facilities, and are used as the inner casing of the soil borrower 4 The gap between the outer casing 3 and the outer casing 3 is 5-15mm, and the inner and outer casings are full-length steel casings; The vibration hammer 1 sinks into the foundation soil; during the sinking process of the inner casing 4, the soil is injected with water through the water pipe installed on the inner wall of the inner casing to soften the soil and reduce the frictional resistance between the soil and the pipe wall , so that the sinking resistance of the inner casing is greatly reduced. As shown in Figure 1, the construction steps of hole forming and pouring of concrete piles are as follows: ...

Embodiment 2

[0040] Embodiment 2: The construction method of the large-diameter vibrating soil-borrowing cast-in-place pile with full sleeve pipe of the present invention includes two processes of hole forming and concrete pouring. The inner and outer casings in the hole forming process are soil-borrowing and hole-forming facilities, and are used as the inner casing of the soil borrower 4 The gap between the outer casing 3 and the outer casing 3 is 5-15mm, and the inner and outer casings are full-length steel casings; The vibratory hammer 1 sinks into the foundation soil; when the vibratory hammer vibrates, the vibratory hammer 1 is pressurized to increase the ability of the inner and outer casings to penetrate the foundation soil; The water pipe on the inner wall of the inner casing injects water into the soil to soften the soil and reduce the frictional resistance between the soil and the pipe wall, so that the sinking resistance of the inner casing 4 is greatly reduced. As shown in Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com