Full-casing hydraulic hammering soil-squeezing cast-in-place pile device and construction method thereof

A technology of hydraulic hammer and cast-in-place pile, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of high price, reduce the bearing capacity of pile foundation, and high construction cost, and achieve the improvement of construction utilization rate and pile side friction. Improve the effect of convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

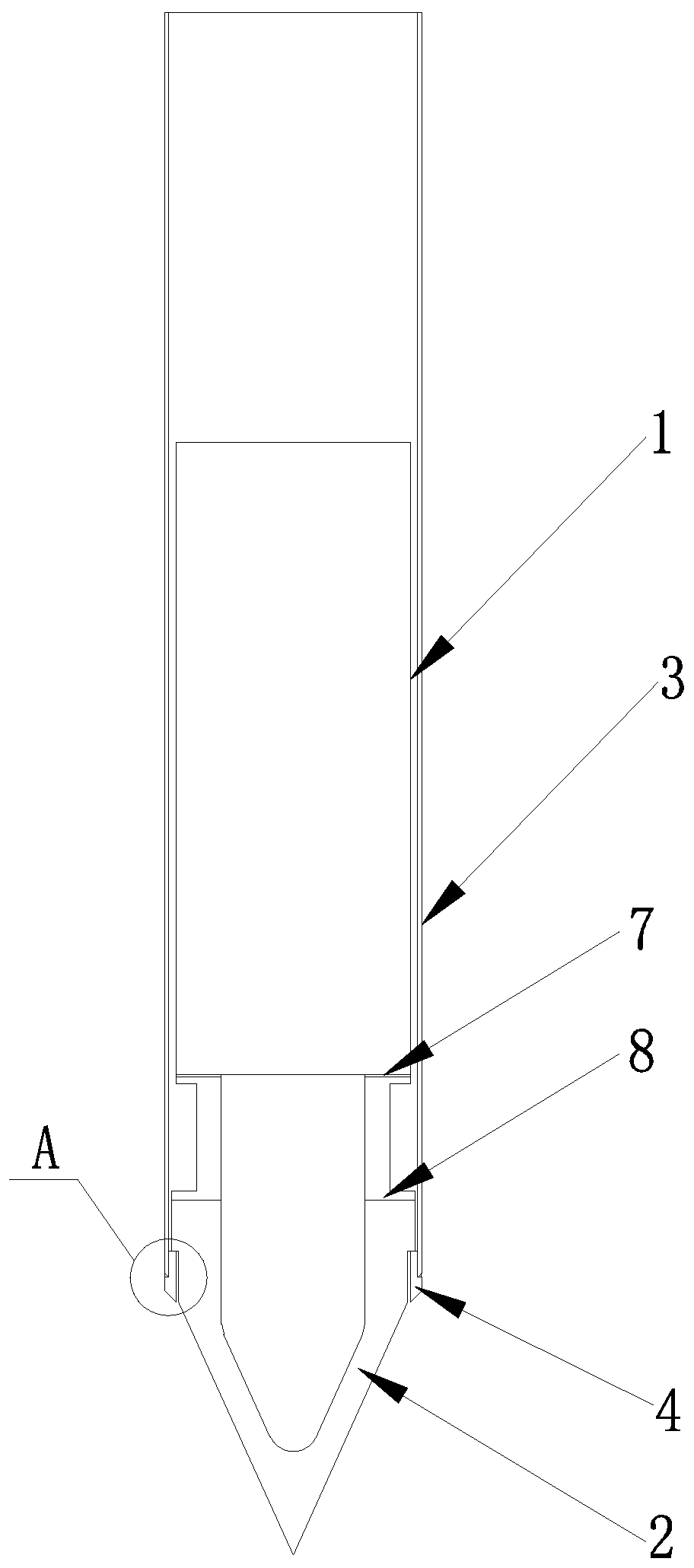

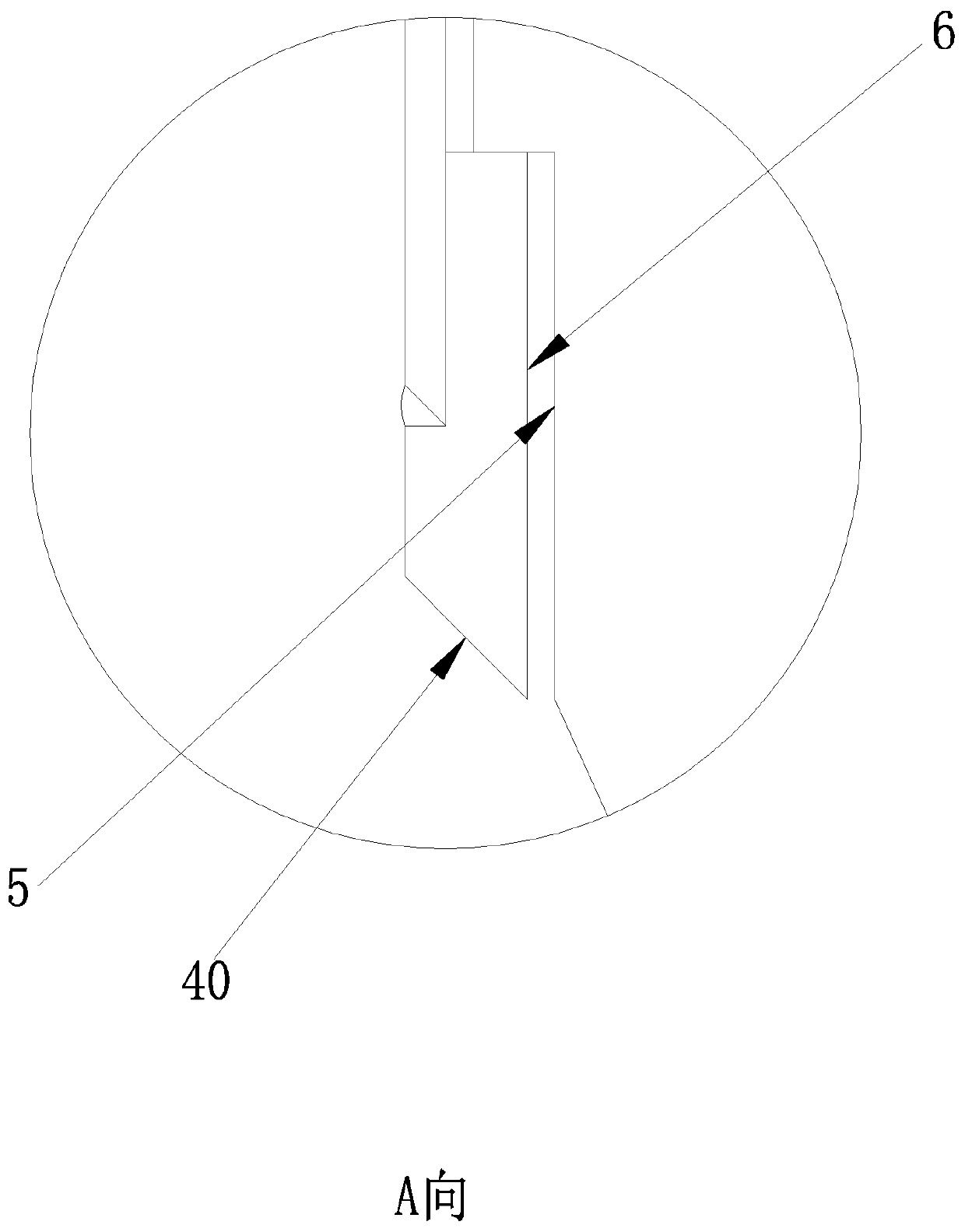

[0044] Such as Figure 1-2 As shown, a full-sleeve hydraulic hammering soil-squeezing cast-in-place pile device provided in this embodiment includes an outer casing 3, a hydraulic hammer 1 sleeved in the outer casing 3, and an inner pile point 2 is fixed at the bottom of the hydraulic hammer 1. Correspondingly, the bottom of the outer casing 3 is fixed with an outer casing spud shoe 4 abutting against the side wall of the inner pile tip 2; the hydraulic hammer 1 drives the inner pile tip 2 to move downward, and then drives the outer casing 3 and the outer casing pile The boots 4 move downward synchronously; the present invention has a simple structure and a reasonable design. On the one hand, the engineering quantity of earthwork and mud transportation is greatly reduced, and the pollution of the surrounding environment by construction dregs and mud is avoided. On the other hand, the crowding of the soil The density improves the pile end bearing capacity and pile side friction...

Embodiment 2

[0062] The construction method of the full-sleeve hydraulic hammering soil-squeezing cast-in-situ pile device of the present invention includes two processes: hole forming and concrete pouring. In the hole forming process, the inner pile tip is hammered with a hydraulic hammer, and the casing follows the pile tip to sink and squeeze the soil to form the hole. , the gap between the inner pile point 2 and the outer casing 3 as the main equipment for soil compaction is 5-15mm on one side, the gap between the pile point 2 and the pipe shoe 4 on one side is 5-10mm, the hydraulic hammer and casing The gap is >10mm on one side, and the casings are full-length steel casings; the inner pile tip 2 and the outer casing 3 sink into the foundation soil under the hammering of the hydraulic hammer, and the construction steps of hole formation and concrete pile pouring are as follows:

[0063] Step 1. Because the foundation soil is hard or the pile depth is deep, the assembled hydraulic hammer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com