Control method of polishing technology

A control method and process control technology, which is applied in the control of workpiece feed motion, grinding/polishing equipment, manufacturing tools, etc., can solve the problem of copper residue on the crystal edge, affecting yield and reliability, and the electrical properties of double metal damascene structures. Uneven problems, to achieve uniform electrical properties, to avoid the effect of crystal edge copper residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

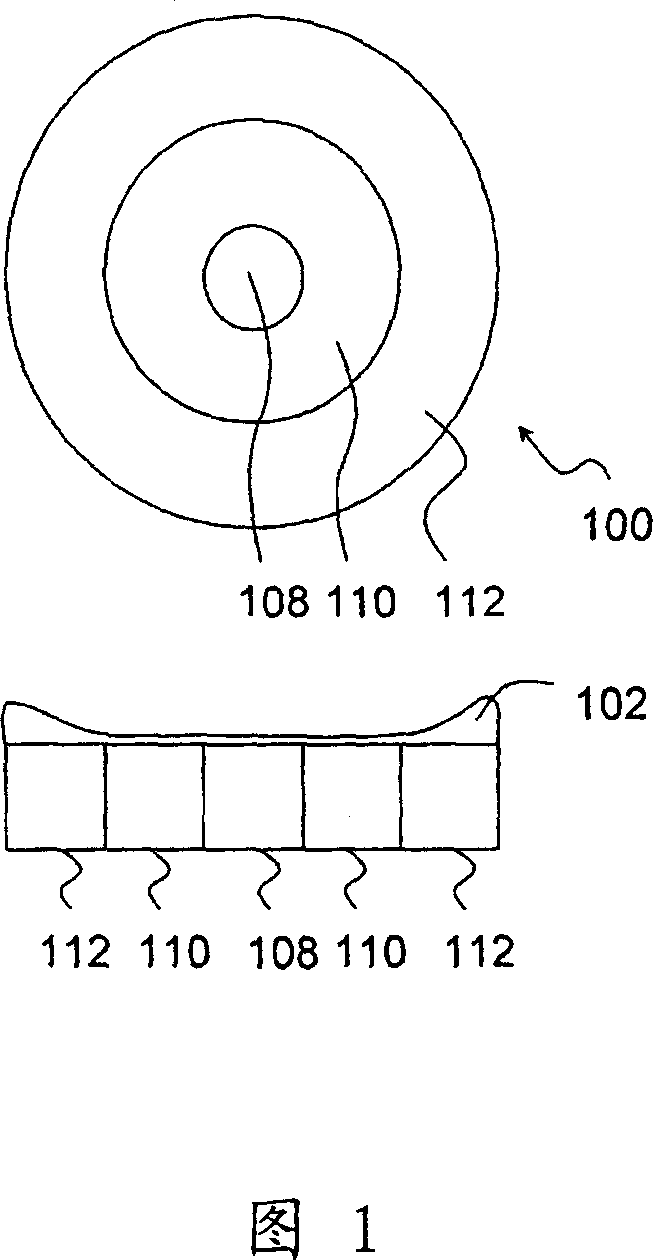

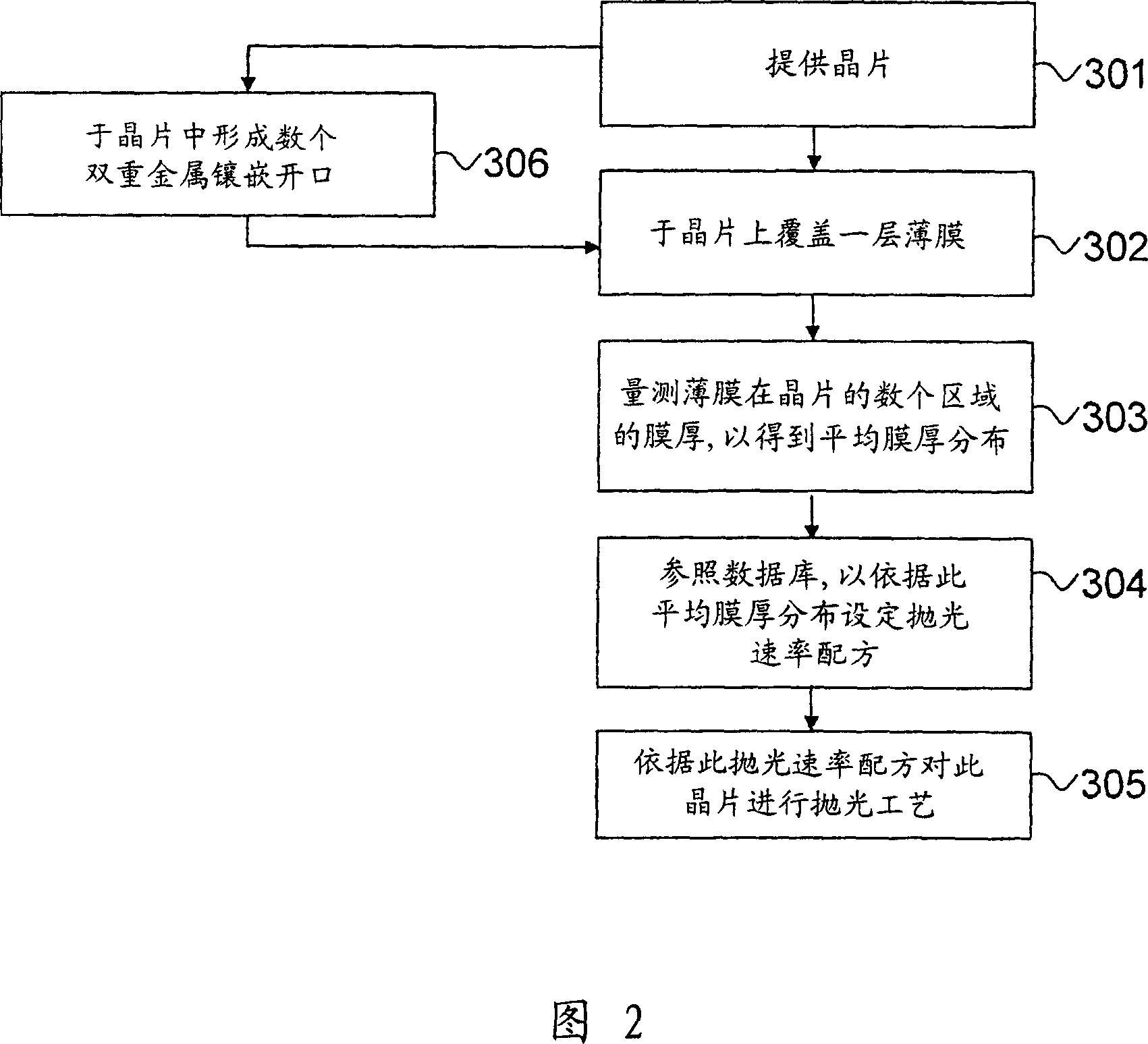

[0041] FIG. 1 is a top view of a wafer 100 and a schematic cross-sectional view along the section line II' according to an embodiment of the present invention. FIG. 2 is a flowchart of a control method for a polishing process according to an embodiment of the invention.

[0042] Please refer to FIG. 1 and FIG. 2 at the same time. Firstly, step 301 is performed: providing the wafer 100 . The wafer 100 is, for example, a 12-inch wafer. Then proceed to step 302 : covering the wafer 100 with a thin film 102 . The material of the thin film 102 is copper, for example. The method of forming the thin film 102 is, for example, an electroplating method or a chemical vapor deposition method.

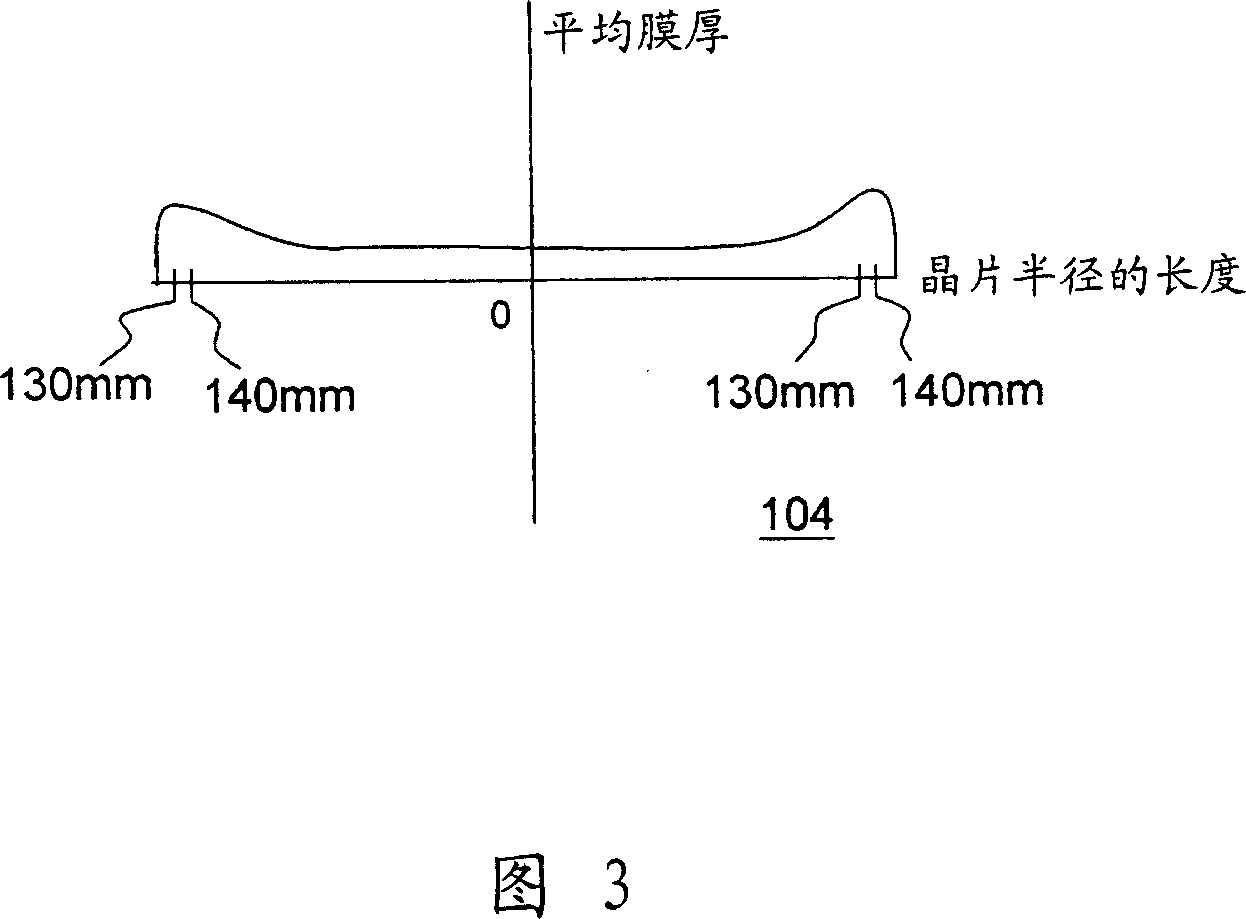

[0043] Next, proceed to step 303 : measure the film thicknesses of the thin film 102 in several regions of the wafer 100 to obtain the average film thickness distribution 104 shown in FIG. 3 . "Distribution of average film thickness" is, for example, a function of wafer radius length and averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com