A tobacco stalk pretreatment equipment

A technology of tobacco stem pretreatment and equipment, which is applied in the field of tobacco stem pretreatment production line, can solve the problems of wasting manpower, material resources, long production cycle, and complicated manual production process, so as to purify the production environment, simplify the production process, shorten The effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

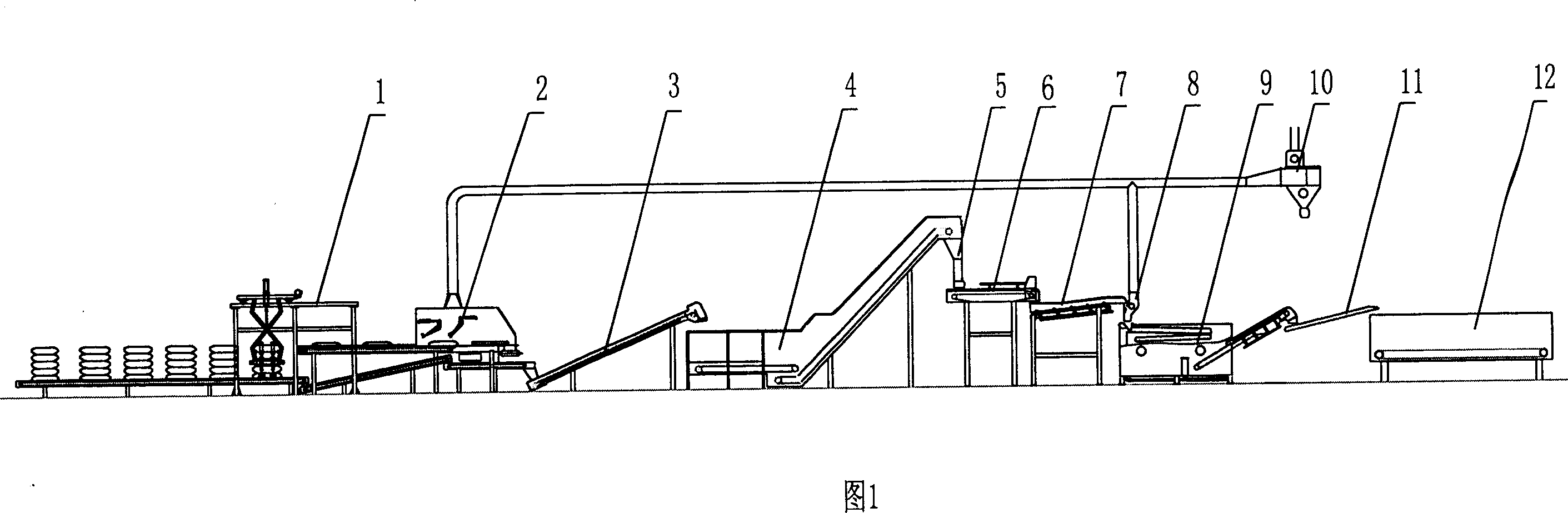

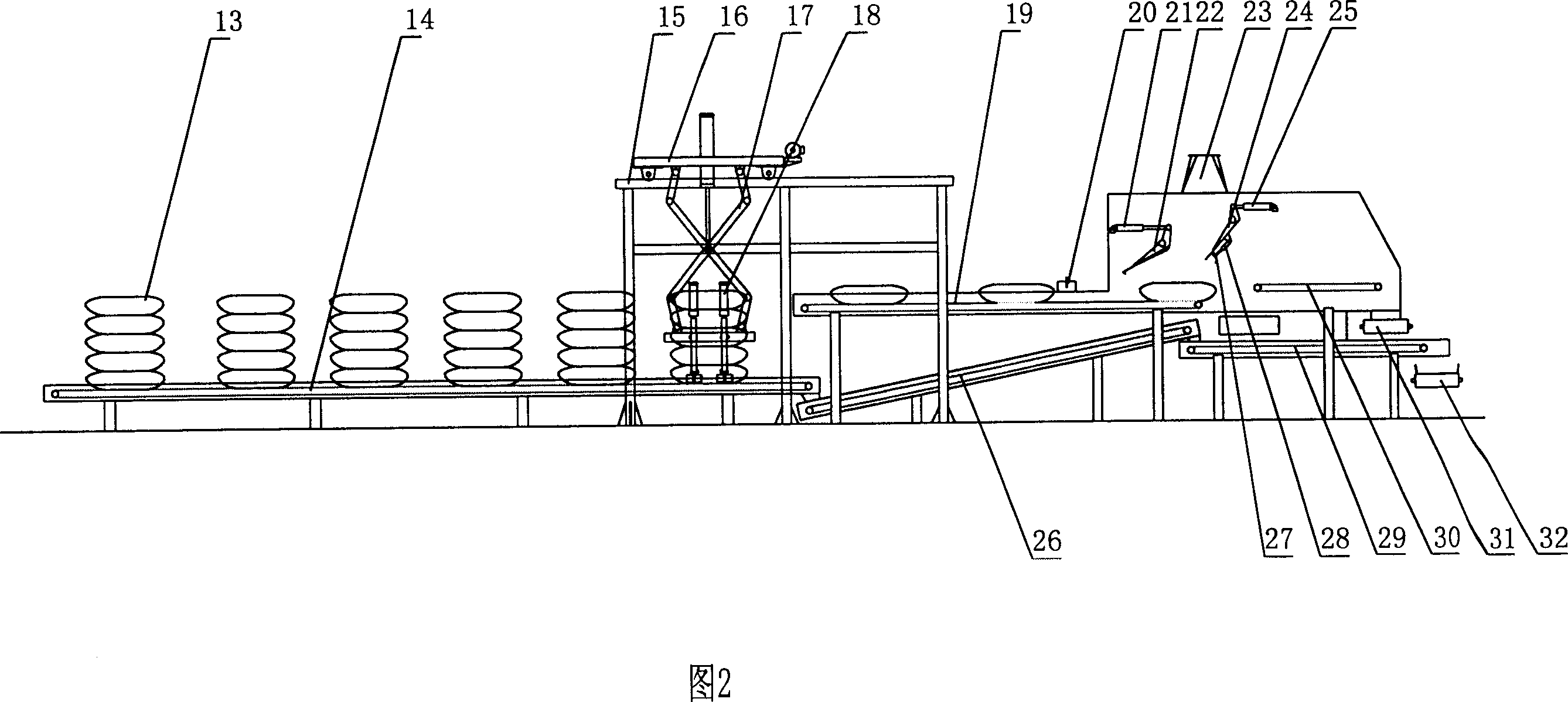

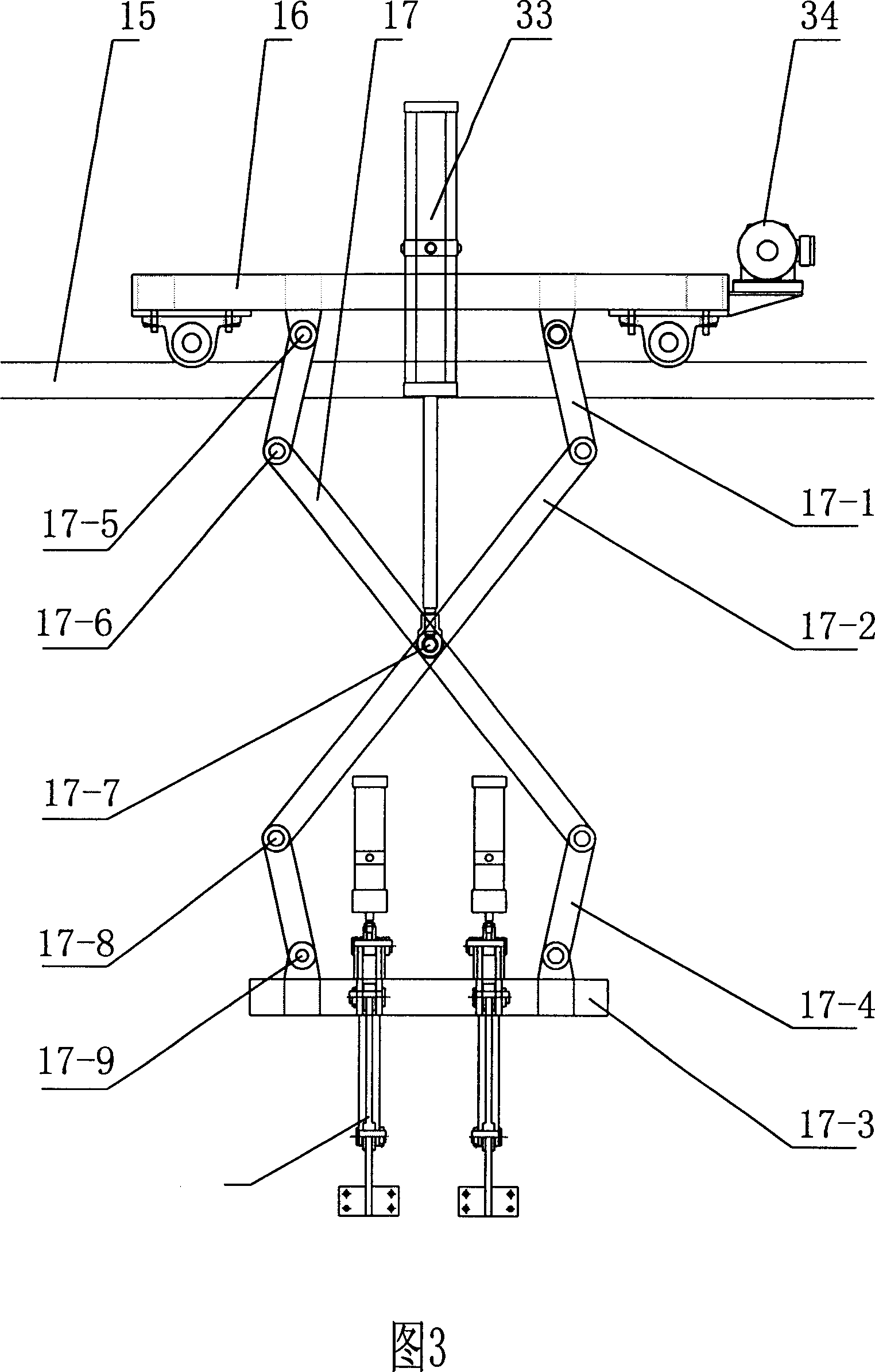

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. As shown in Figure 1, the tobacco stem pretreatment production line involved in the present invention is composed of a packaging device 1, an unpacking device 2, a connecting device 3, a bin feeder 4, a metering tube 5, a metering scale 6, a vibrating conveyor 7, It is composed of winnowing equipment 8, water washing and dampening equipment 9, blanking equipment 10, conveying equipment 11, stem storage equipment 12 and other equipment. The main production process includes:

[0036] 1. Package:

[0037] After the tobacco stems packed in sacks enter the production workshop, in order to save space, they are generally placed in stacks of 4 packs or 5 packs. In the production process, the sacks are first lifted from the ground by a forklift, and placed in stacks on the conveyor belt at the bottom of the bagging equipment 1, and then the sacks are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com