Composite rectifying device for current generating system of deep water basin

A technology of deep water test and rectification device, which is applied in the field of ships and ocean engineering, can solve problems such as undiscovered, and achieve the effect of easy realization, simple structure and shortened distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

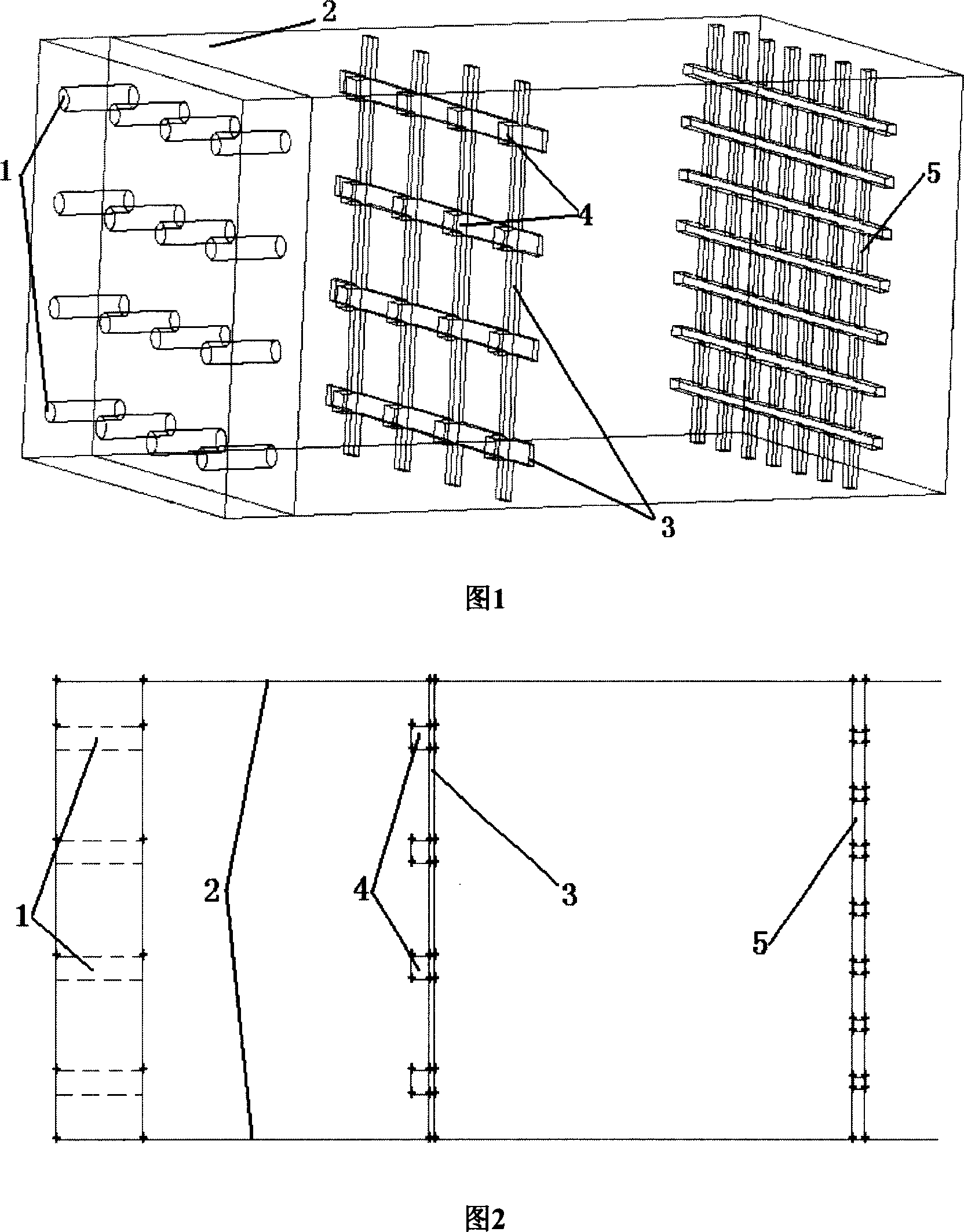

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The structural layout of the compound rectification device of the flow-making system of the deep-water test pool of the present invention is shown in Figure 1. A rectifying plate is installed at a distance between 0.1m and 0.4m from the exit of the flow-making nozzle 1, and the rectifying plate is supported by The frame 3 and the rectification block 4 constitute. The supporting frame 3 is constructed into a grid shape by criss-crossing slender slats, and its outer ends are fixed on the walls 2 around the pool. A rectifying block 4 is installed at each cross point where the supporting frames 3 intersect, and the rectifying block 4 corresponds to each nozzle on the flow-making nozzle 1 respectively. The size of the rectifying block 4 corresponds to the size of the aperture of the flow-making nozzle 1 .

[0020] The shape of the rectifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com