The high-frequency circuit structure for the mutual conversion of the coaxial electric mode of the rectangular waveguide mode and round waveguide

A rectangular waveguide and high-frequency circuit technology, applied in circuits, waveguide-type devices, electrical components, etc., can solve the problem that the gyrotron is not well solved, and achieve the effects of simple structure, small mode distortion, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

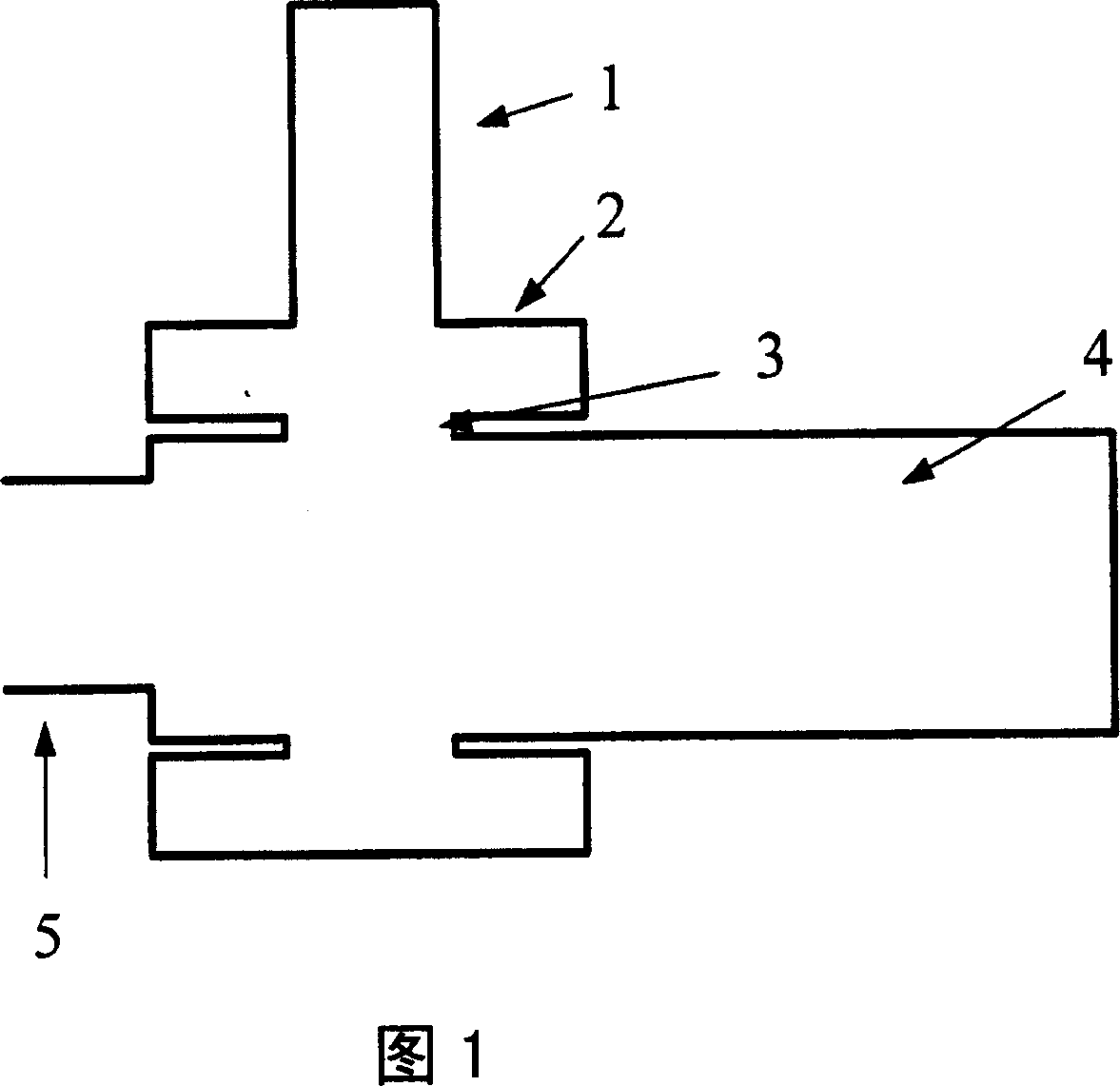

[0009] The high-frequency circuit structure of the present invention adopts the rectangular waveguide side input cylindrical resonant cavity, and utilizes the rectangular waveguide TE 10 The mode excites the TE of the coaxial resonator n1 mode, the electromagnetic field energy excites the circular electric mode TE in the circular waveguide through the periodically arranged coupling holes 0n mold.

[0010] As shown in FIG. 1 , the rectangular waveguide 1 and the circular waveguide 4 are connected orthogonally, and their central axes are perpendicular to each other. At the junction of the rectangular waveguide 1 and the circular waveguide 4, the sides are respectively connected to the inner and outer walls of the coaxial resonant cavity 2, the coaxial resonant cavity 2 is connected to the circular waveguide 4 through the coupling hole 3, and one end of the circular waveguide 4 is connected to the working mode TE 0n Circular waveguide 5 with mode cut-off; coupling hole 3 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com