Attachment method for piezoelectric elements

a piezoelectric element and piezoelectric technology, applied in the field of piezoelectric element attachment method, can solve the problems of high activity quotient, prior art has not provided an orifice plate-based continuous-action dispenser, and can not be easily portable, battery-operated, and convenient refilling. , the effect of convenient refilling and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

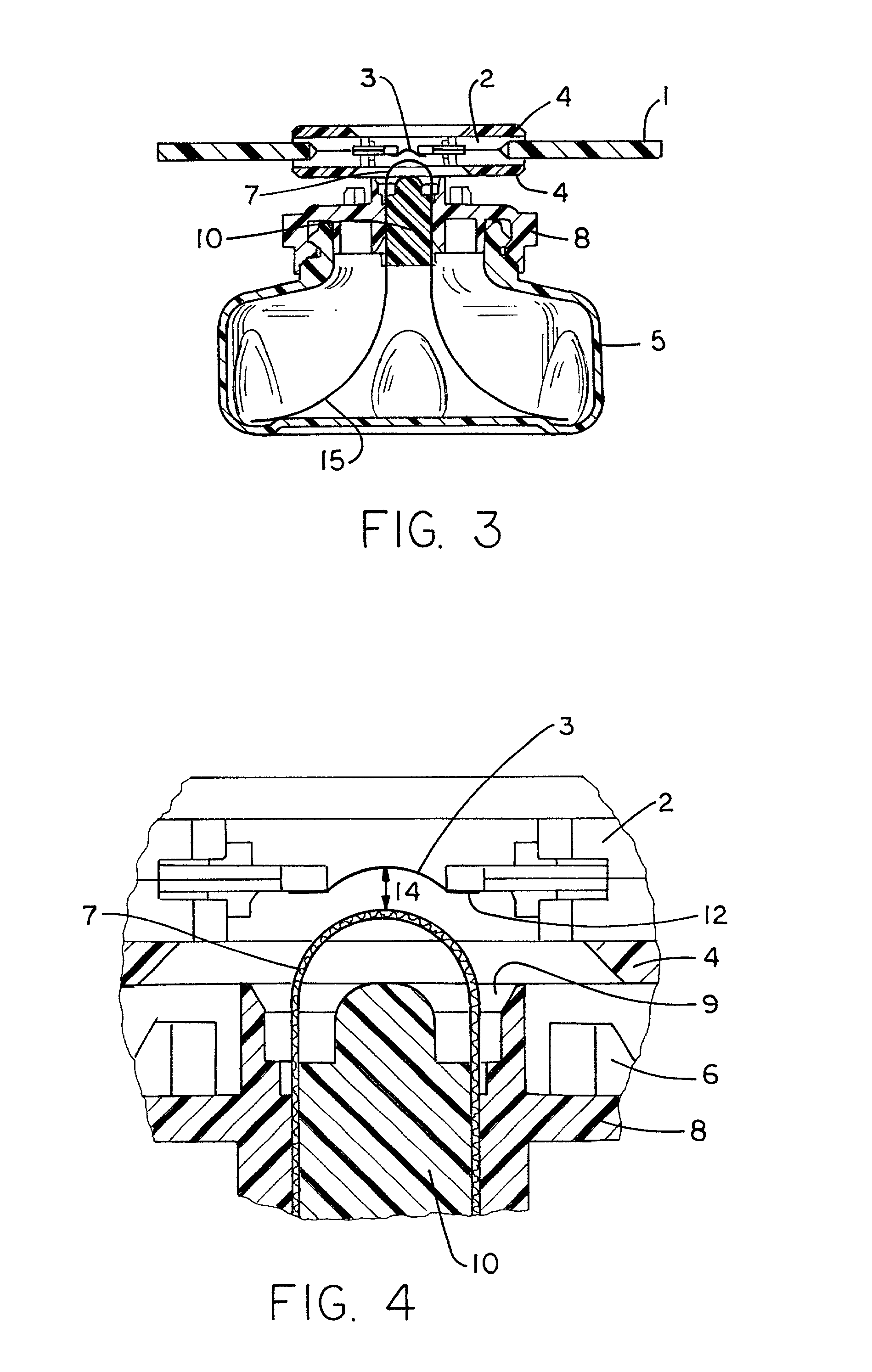

[0024] While FIGS. 1 through 6 are more specifically directed to a preferred embodiment of the invention, FIGS. 7 and 8 are more generally directed to the full scope of the present invention, which envisions joining of the piezoelectric element to the orifice plate in a manner which is in contrast to the conventional practice of those of ordinary skill in the art.

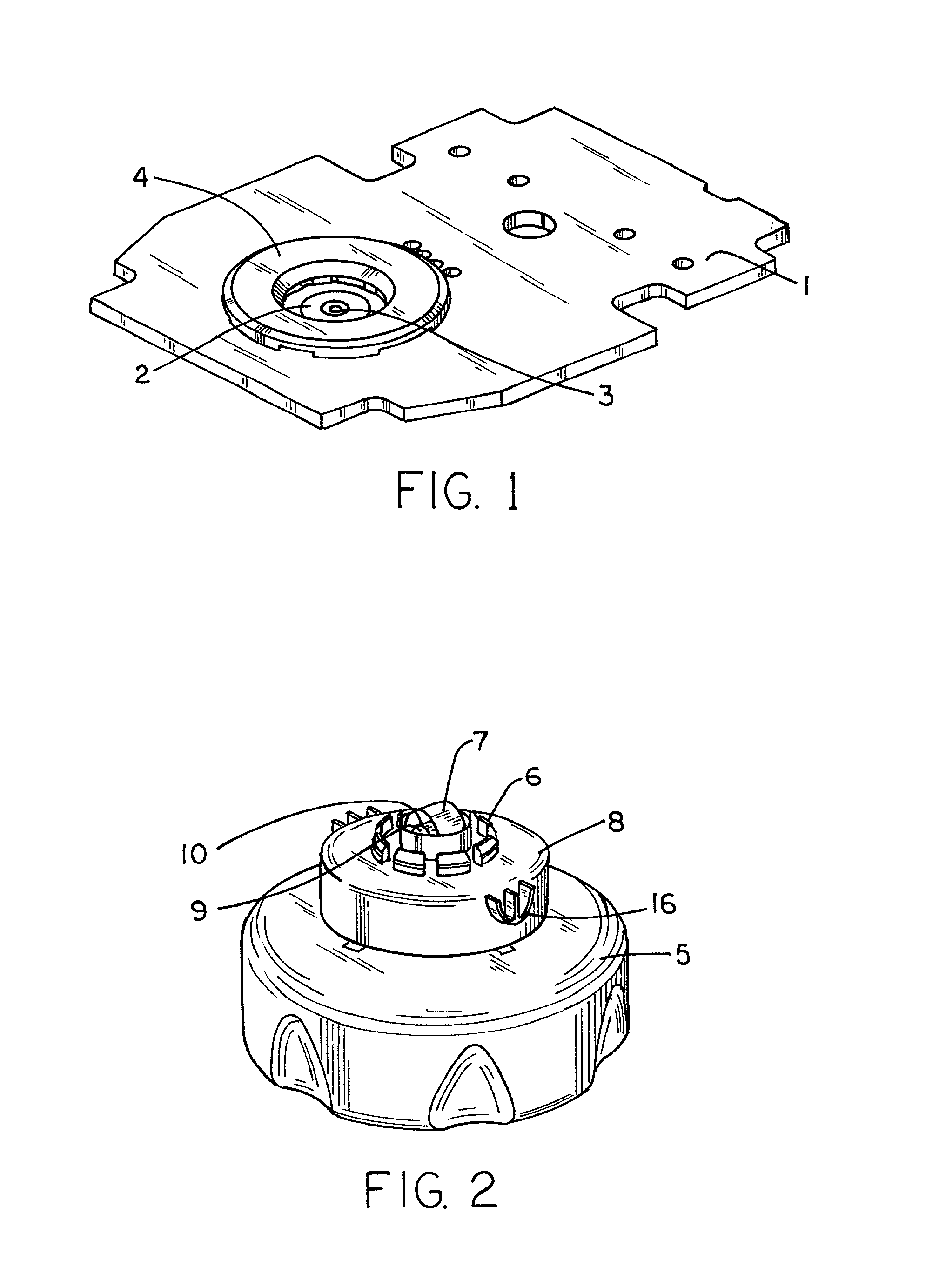

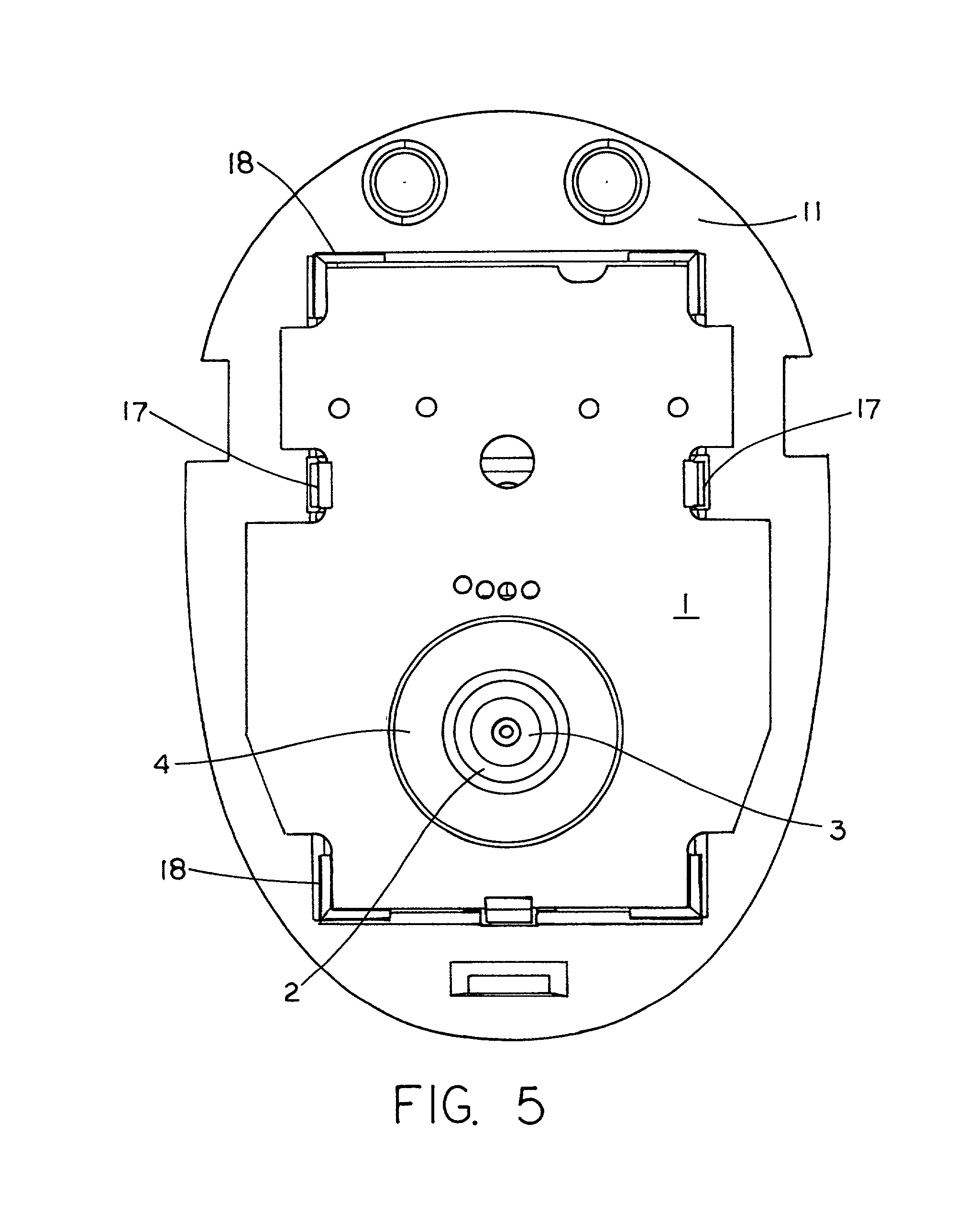

[0025] FIG. 1 illustrates the general relationship between a printed circuit board, 1, in which the piezoelectric element 2 is located. The circuit board, 1, is illustrated without the electronic circuitry and battery associated therewith for clarity and ease of understanding of the present invention. It is also to be understood that the circuit board is, in use, attached to the chassis of a dispenser, which chassis is in turn placed in a decorative shell-like housing or receptacle (not shown) for use. The chassis board 11 is shown in top view in FIG. 5, while the housing is not illustrated. The decorative receptacle or hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com