Apparatus for making dimensionally stable nonwoven fibrous webs

a nonwoven fibrous, dimensionally stable technology, applied in the direction of dough shaping, manufacturing tools, food shaping, etc., can solve the problems of affecting the use of pet in high temperature applications, the melting point and the glass transition temperature, and achieve the effect of reducing the change in fiber diameter, size or physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

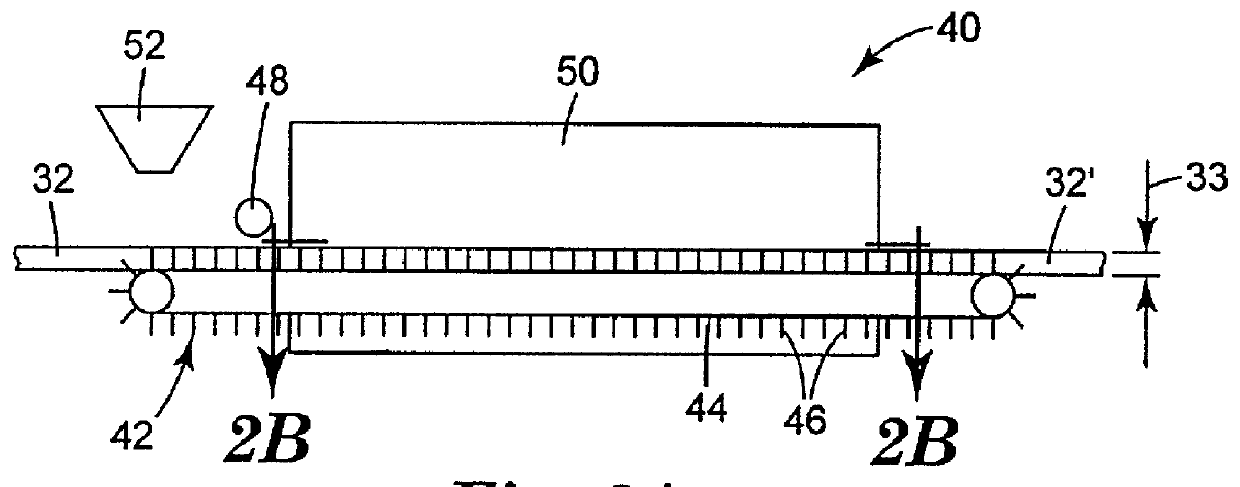

[0037] FIG. 1 is a perspective view of an annealing apparatus 20 designed to hold a nonwoven fibrous web 21 stationary at a plurality of tentering points during annealing or heatsetting. A plurality of retractable tentering pins 22 are mounted to a tentering pin support 24. In the embodiment illustrated in FIG. 1, the tentering pins 22 are inserted through a plurality of tentering pin holes 26 on a backing 28. The tentering apparatus 20 of FIG. 1 restrains the nonwoven web 21 along its major surface (x and y axes), but not along the z-axis. The tentering pin support 24 and the backing 28 includes a plurality of vent holes 30 to permit airflow through the surface of a nonwoven web 21 engaged with the annealing apparatus 20. The tentering apparatus 20 avoids compressing the nonwoven web 21 of microfibers during annealing to preserve the acoustical and thermal insulating properties.

[0038] Unlike conventional edge tentering used to anneal films and woven fabrics, the tentering pins 22 o...

examples 11-14

[0088] Polyethylene terephthalate (PET) nonwoven meltblown microfibrous webs with a targeted basis weight of 200 grams / meter.sup.2 were produced as described in Examples 1-5. The PET meltblown microfibrous webs were prepared from various Intrinsic Viscosity PET resins set forth in Table 3 (available from 3M Company and from Eastman Chemical Products, Inc. of Kingsport, Tenn.). The annealed webs were evaluated for the effect of I.V. on unrestrained web shrinkage in accordance with ASTM D 1204-84. The results are set forth in Table 3.

3TABLE 3 Example PET Resin % Unrestrained Shrinkage Machine No. Identification I.V. Direction 200.degree. C. / 10 minutes 11 3M 651000 0.60 57.1 12 Eastman 12440 0.74 58.3 13 Eastman 9663 0.80 58.3 14 Eastman 12822 0.95 57.1

[0089] The data of Table 3 show that I.V. did not appear to be an influencing factor on PET web dimensional stabilization within the range of 0.60 to 0.95 I.V.

example 16

[0093] A PET nonwoven acoustical insulating web was prepared as described in U.S. Pat. No. 4,118,531 (Hauser). The webs comprised 65% melt blown microfibers prepared from polyethylene terephthalate (PET) 0.6 I.V. type 651000 available from 3M Company of St. Paul, Minn. The webs also included 35% crimp bulking fibers in the form of 3.8 cm (1.5 inch) long, 6 denier (25.1 micrometers in diameter), 3.9 crimps / centimeter (10 crimps per inch) polyester staple fibers available as Type T-295 fibers from Hoechst-Celanese Co. of Somerville, N.J. The resulting web of Example 16 was tenter annealed or heatset with the tentering apparatus of Example 15.

[0094] The sample of Example 16 was tenter annealed for 10 minutes at 180.degree. C. using the tentering apparatus described in Example 1-5. The sample was removed from the oven, allowed to cool to room temperature, and removed from the tentering device. The sample of Example 16 had a web thickness of 3.4 centimeters and was evaluated in accordanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com