Vapor delivery system for solid precursors and method of using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

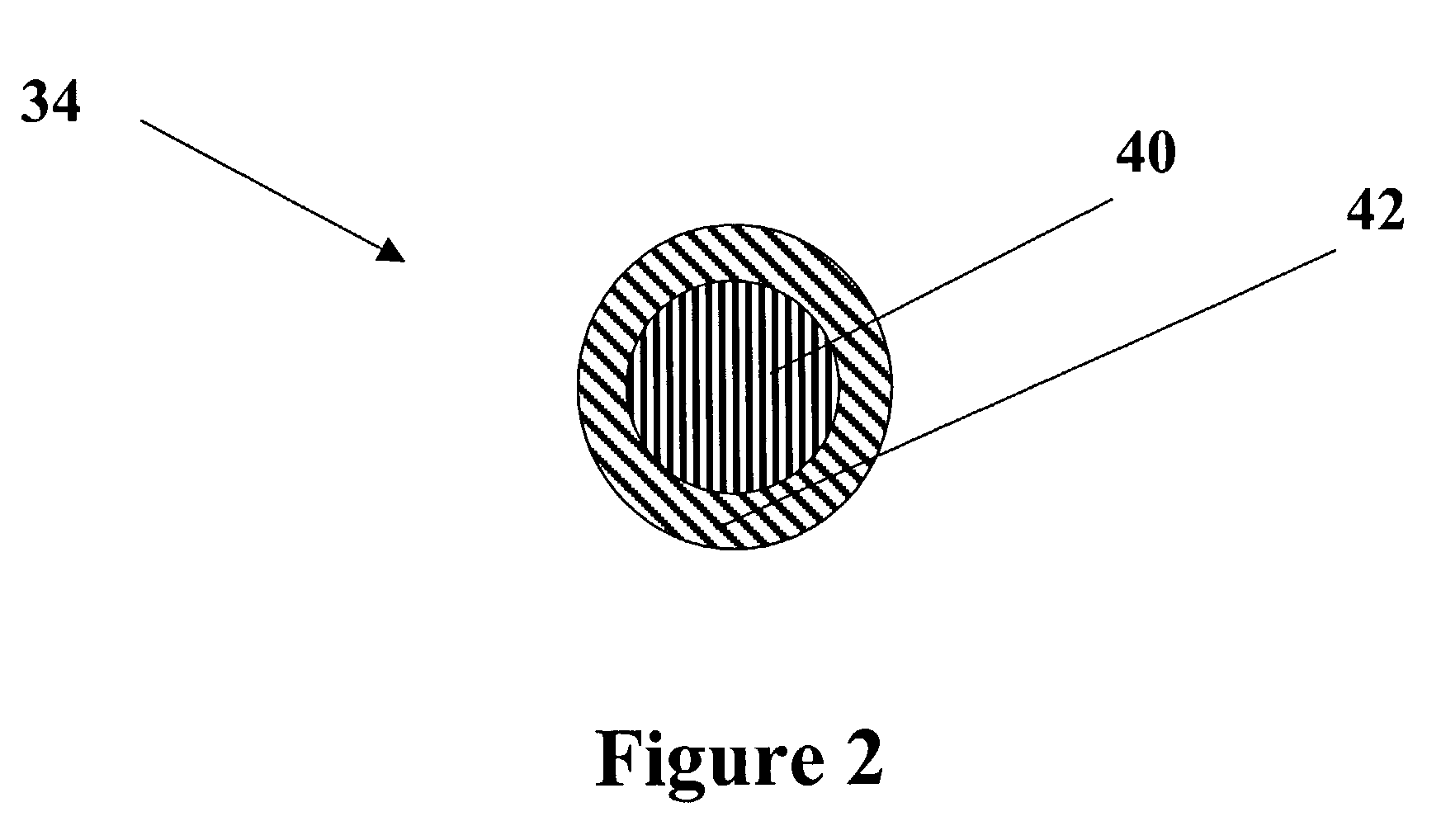

[0063] Generally, the vapor delivery system described herein utilizes a sublimatable solid precursor material applied to a metallic substrate, such as a wire. The coated substrate is drawn through a heated internal chamber at a predetermined speed to rapidly heat and vaporize the sublimatable solid precursor. The vaporization continues until the desired amount of solid precursor is vaporized. The vapor delivery system of the present invention vaporizes a known amount of precursor and achieves continuous uninterrupted delivery of the vaporized solid precursor to a downstream process chamber in reproducible fashion. Further, the present invention allows the user to vaporize sufficient quantities of a solid precursor material to meet the flow rates required for typical deposition applications.

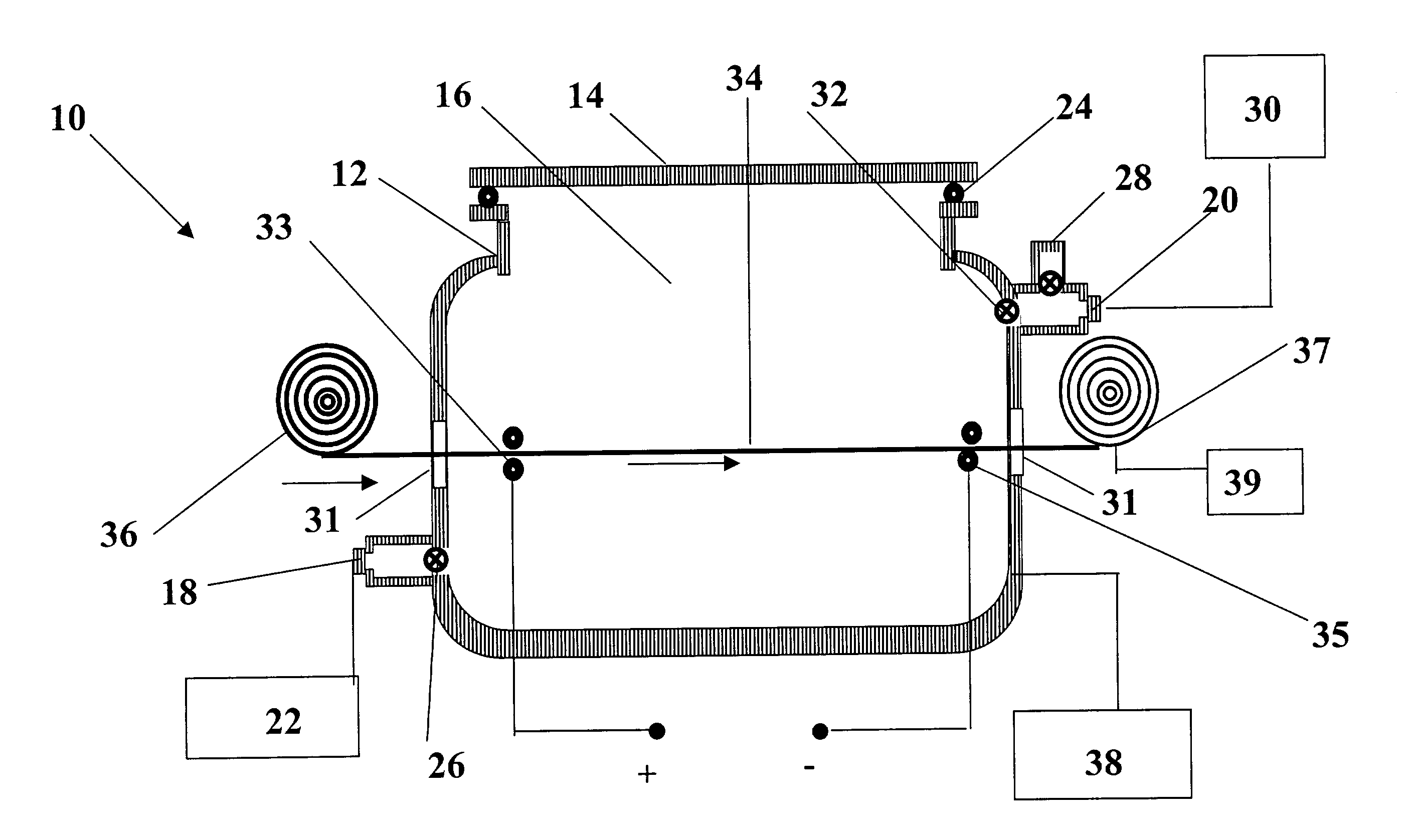

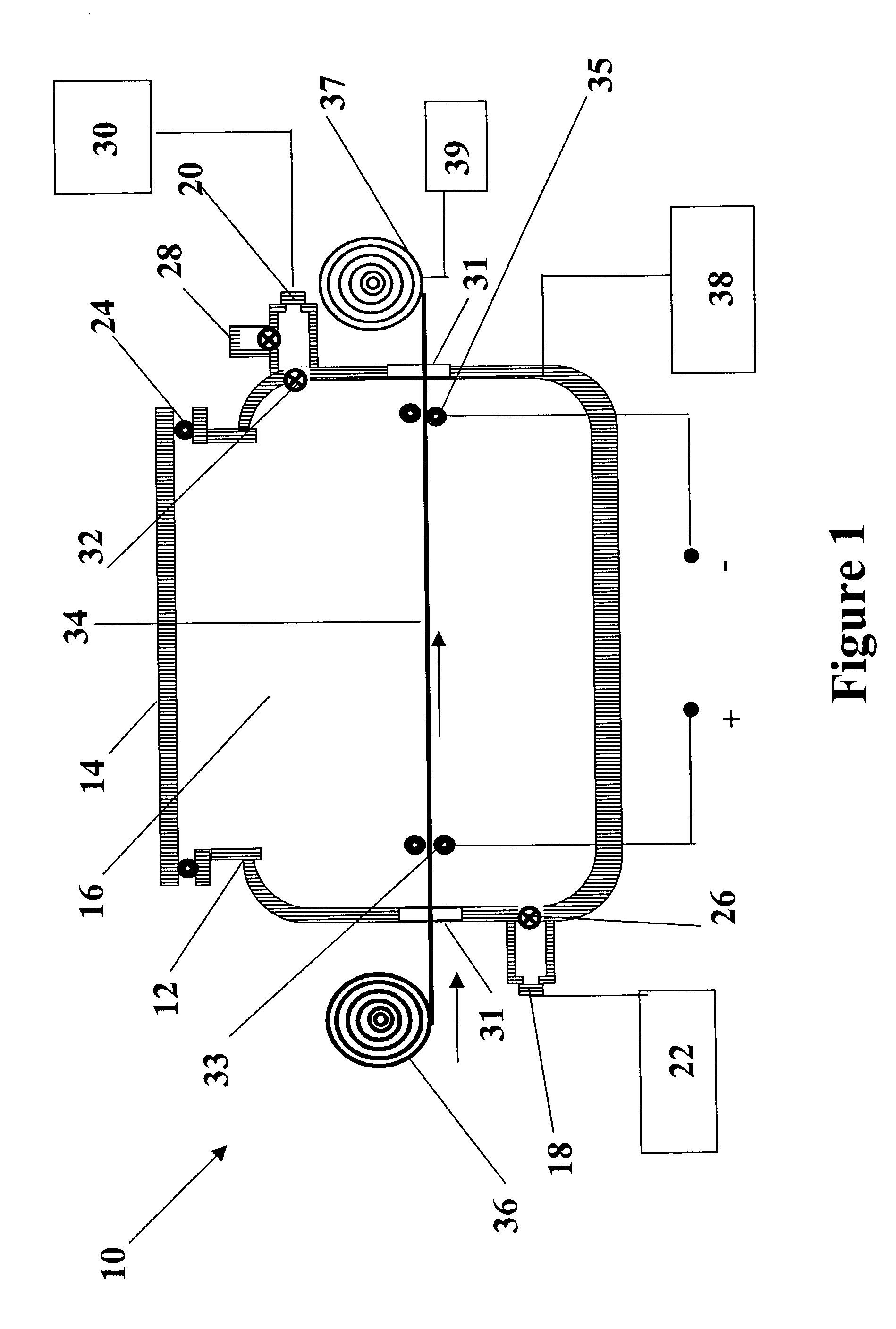

[0064] One embodiment of the present invention is a vapor delivery system described with reference to FIG. 1. The vaporizer delivery system 10 comprises a housing 12, a sealable cover plate 14 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com