Plating apparatus and plating method

a technology of plating apparatus and plating method, which is applied in the direction of electrolysis components, conveyor parts, transportation and packaging, etc., can solve the problems of poor quality of plated film, low material cost, increased cost, etc., and achieves the effect of easy formation of plated film and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

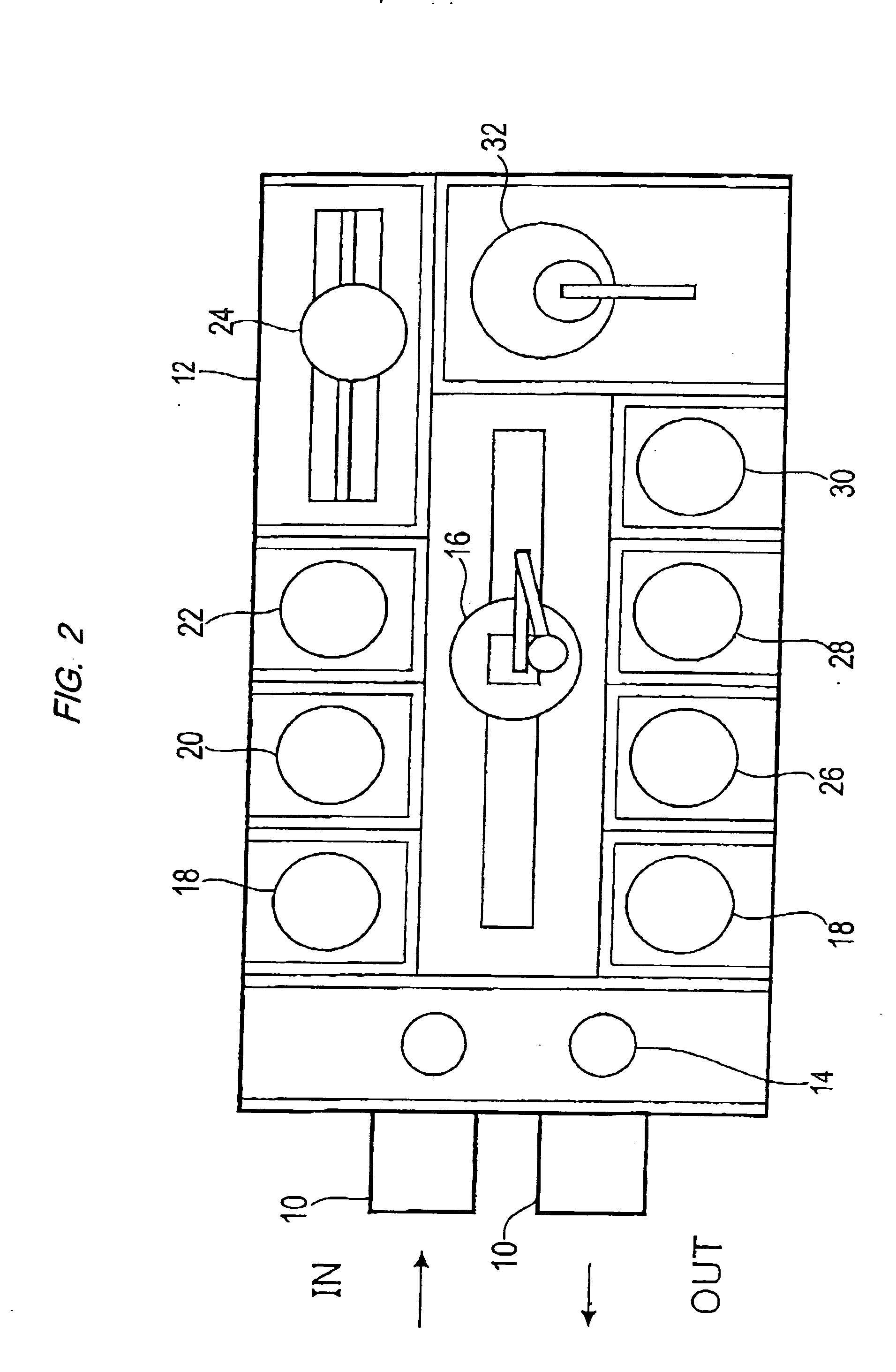

[0059] A plating apparatus and a plating method according to embodiments of the present invention will be described below with reference to the drawings. The following embodiments show examples in which copper as an interconnect material is embedded in fine recesses for interconnects formed in a surface of a substrate such as a semiconductor wafer so as to form interconnects composed of a copper layer. However, it should be noted that other kinds of interconnect materials may be used instead of copper.

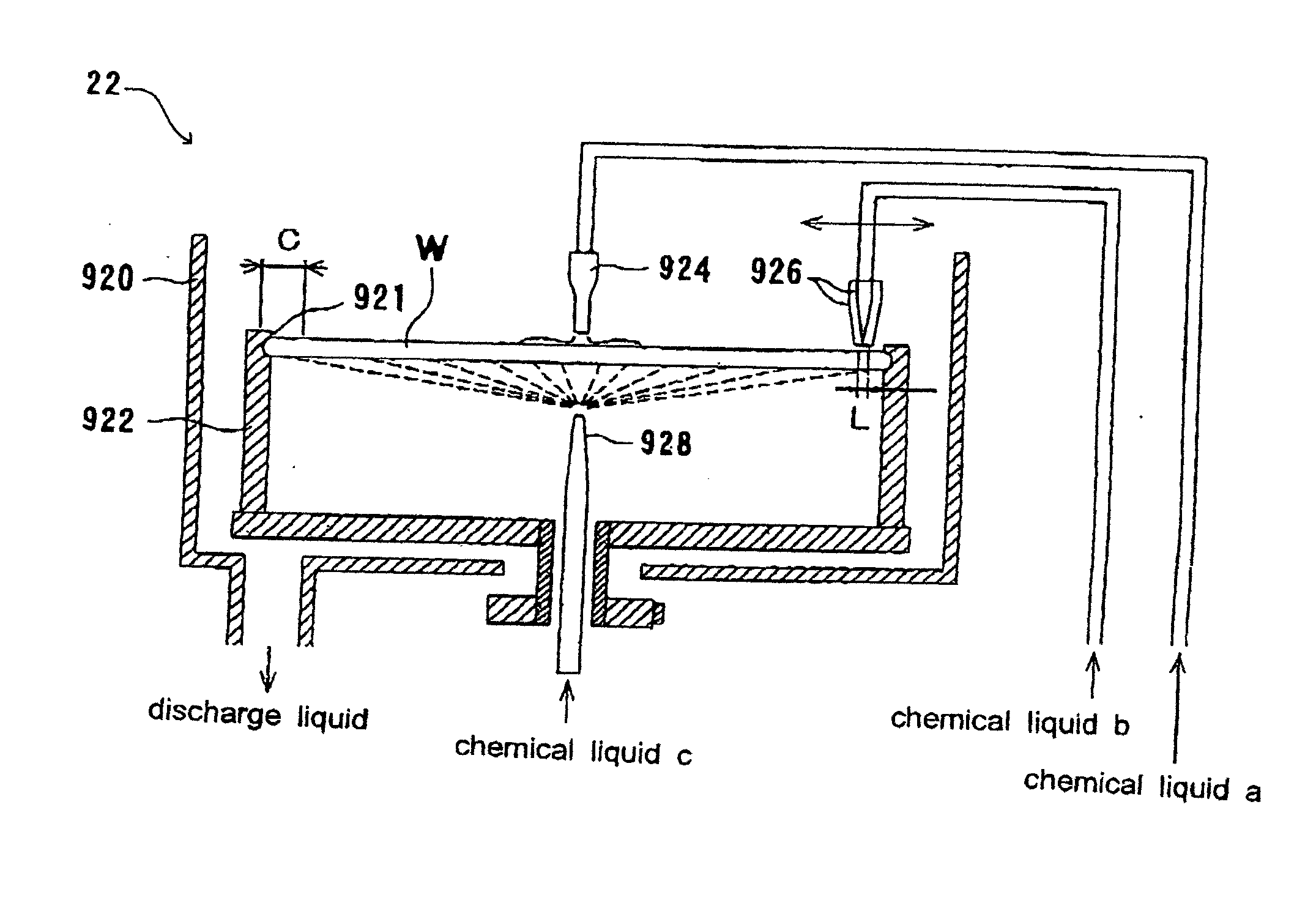

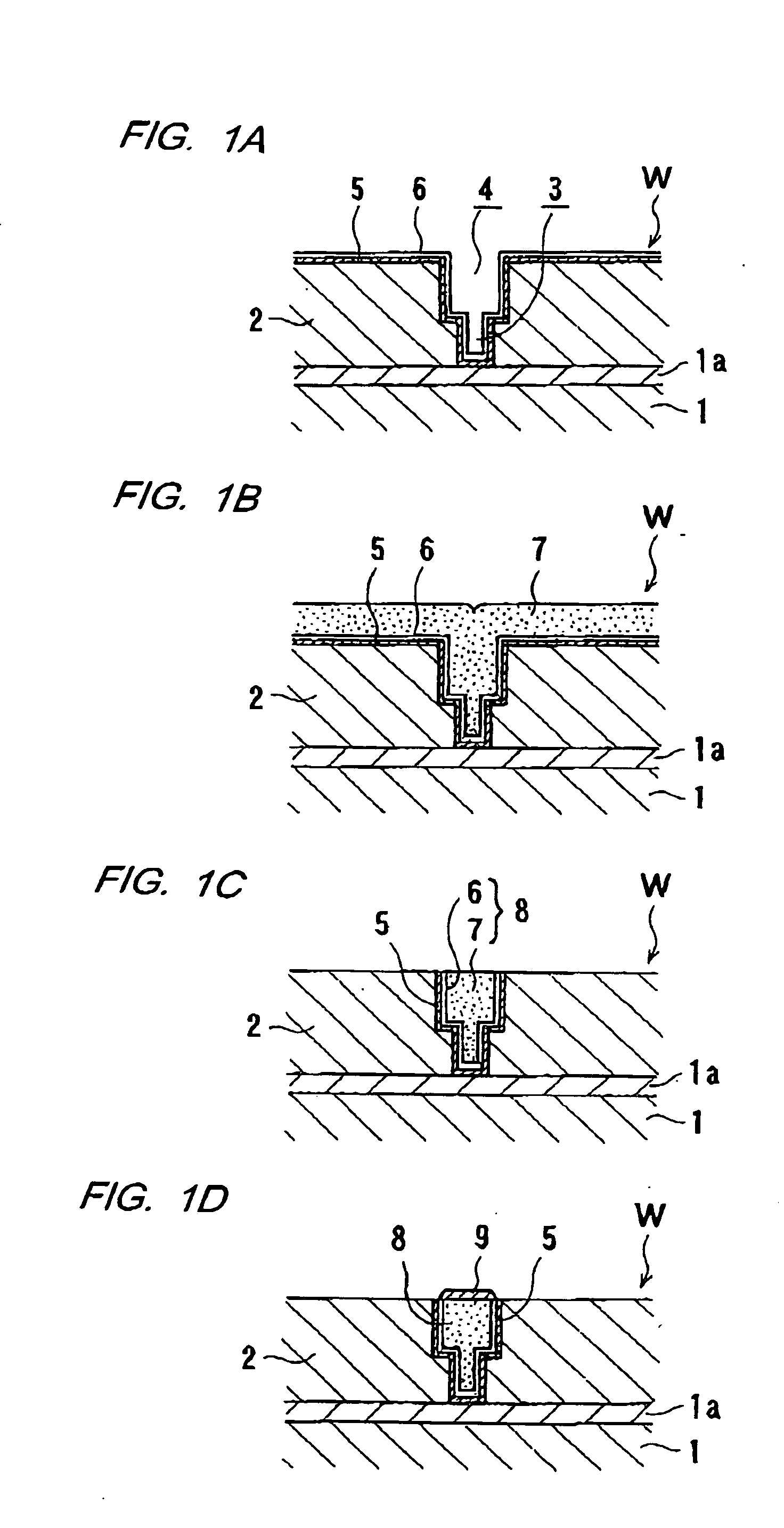

[0060]FIGS. 1A through 1D illustrate an example of forming copper interconnects in a semiconductor device. As shown in FIG. 1A, an insulating film 2, such as an oxide film of SiO2 or a film of low-k material, is deposited on a conductive layer 1a formed on a semiconductor base 1 having formed semiconductor devices. Via holes 3 and trenches 4 are formed in the insulating film 2 by performing a lithography / etching technique so as to provide fine recesses for interconnects. Thereafter, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com