Light emitting device and electric device using the same

a technology of light emitting devices and electric devices, applied in static indicating devices, organic semiconductor devices, instruments, etc., can solve problems such as hard to generate noise, deterioration of luminance, and major problems of reliability of devices, and achieve the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

Embodiment 1

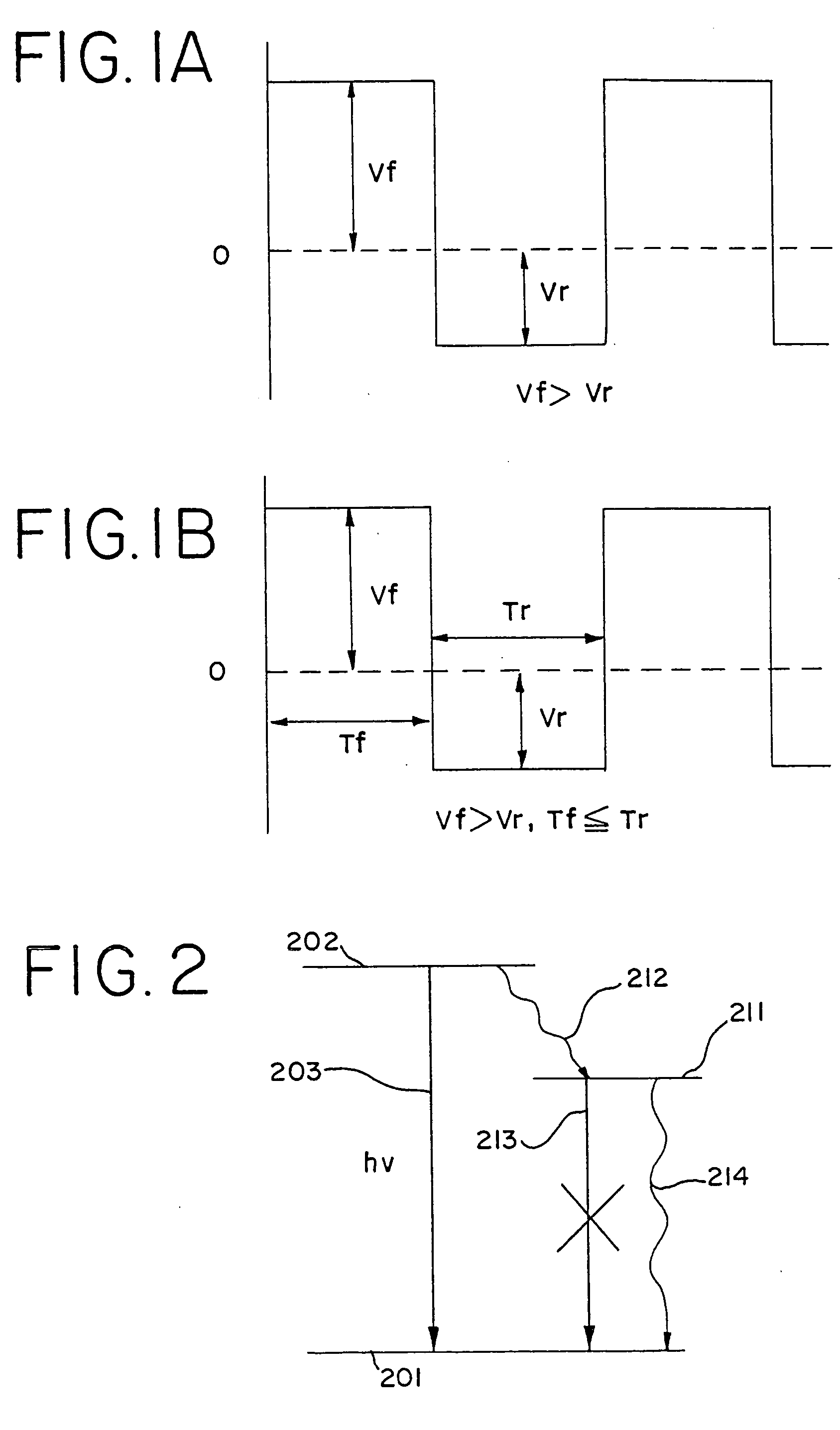

[0073] In the embodiment, in a organic light emitting element in which a polymer compound producing light emission was applied as an organic compound layer and a layer including a conductive polymer compound was disposed between an anode and the organic compound layer, luminance deterioration was measured in the constant voltage alternating current drive (the drive in which both the forward bias and the reverse bias are set to a fixed voltage).

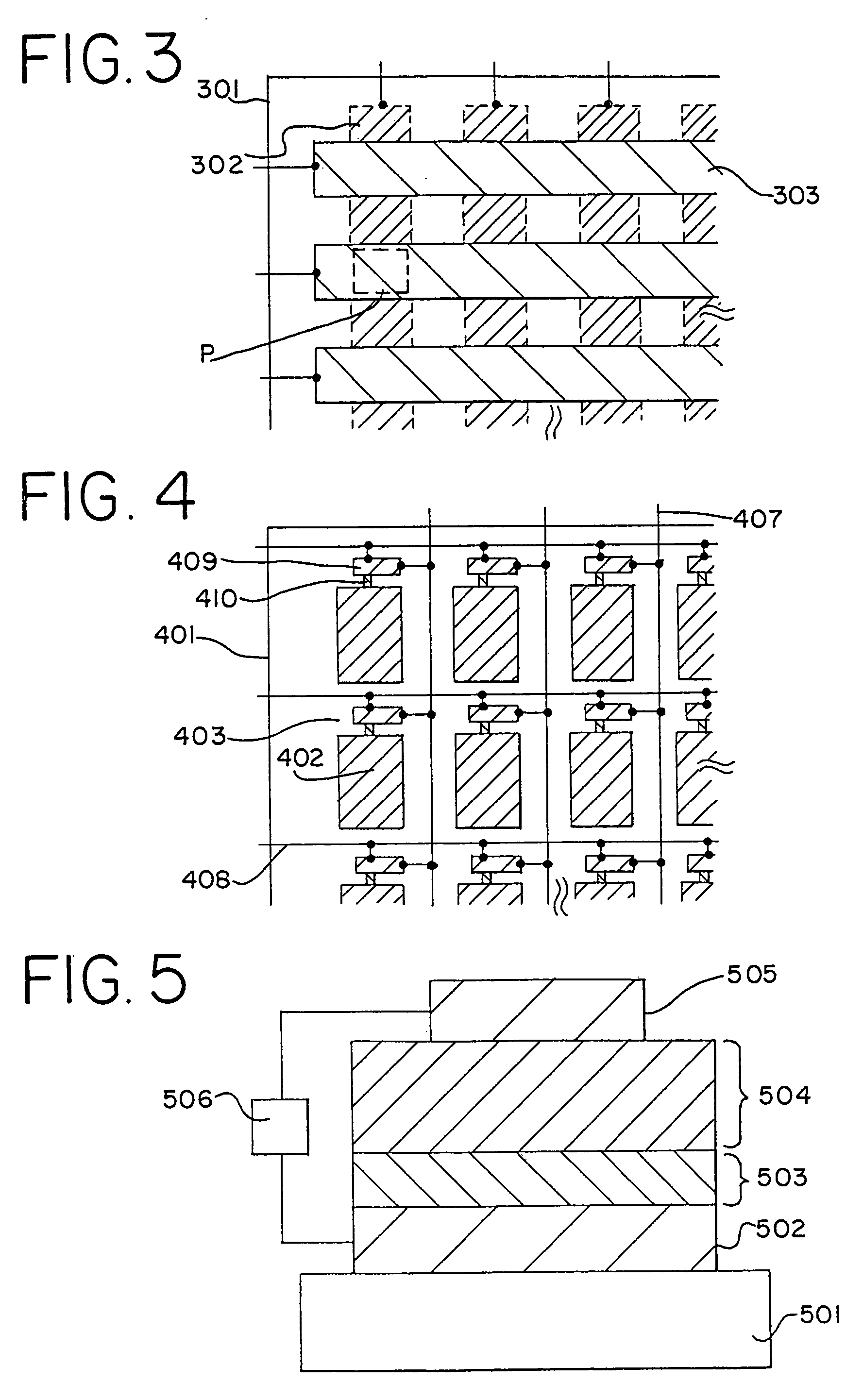

[0074]FIG. 5 shows a device structure. First, an aqueous solution of 1.3 wt % of PEDOT / PSS was applied to a glass substrate 501 deposited with ITO of a thickness of 110 nm as an anode 502, and the substrate was baked at a temperature of 100° C. for one hour to form a layer 503 containing a conductive polymer compound. The film thickness was formed to be about 30 nm.

[0075] Subsequently, the substrate was vacuum-baked at a temperature of 80° C. for three minutes, and a toluene solution of 0.16 g of poly(p-phenylene vinylene) deriva...

embodiment 2

[0080] In this embodiment, the same device as Embodiment 1 was fabricated, and the reliability of the device was measured as the driving conditions were slightly varied. The constant voltage alternating current drive was performed where a forward bias was 3.8 [V], a reverse bias was 1.4 [V], a duty ratio was 50%, and a frequency was 600 Hz (the initial luminance at this time was about 300 cd / cm2). The result is shown by Plot AC in FIG. 7. About 60% of the initial luminance was maintained even after about 700 hours passed.

embodiment 3

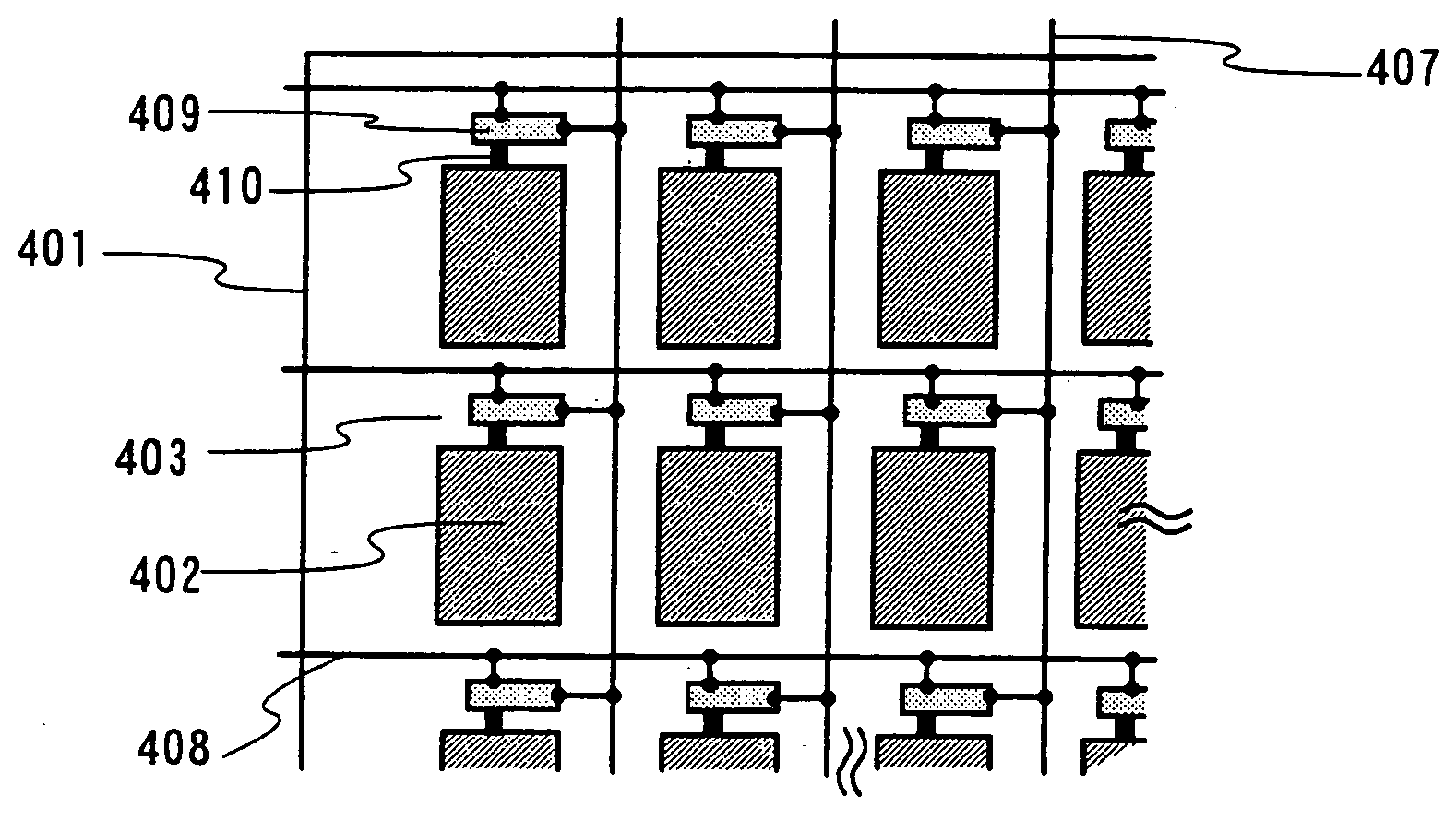

[0083] An example of a passive matrix light emitting device is shown in Embodiment 3 as an example of a light emitting device disclosed by the present invention. A top view thereof is shown in FIG. 8A, and a cross sectional diagram of FIG. 8A cut along a line P-P′ is shown in FIG. 8B. In addition, element structures of the organic light emitting element can be various, the compositions such as ones shown in Embodiments 2 and 3 may be adapted.

[0084] Reference numeral 801 denotes a substrate in FIG. 8A, and glass is used for the substrate here. A plastic material also can be used; as the plastic material, polyimide, polyamide, acrylic resin, epoxy resin, PES (polyether sulfile), PC (polycarbonate), PET (polyethylene terephthalate), or PEN (polyethylene naphthalate), which are in a plate shape, or a film shape can be used.

[0085] Reference numeral 802 denotes a scanning line (anode) made from an oxide conductive film, and an indium tin oxide (ITO) is used in Embodiment 3. Further, ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com