Hydroisomerization processes using sulfided catalysts

a technology of sulfide catalysts and hydroisomerization processes, which is applied in the direction of hydrocarbon oil treatment products, physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, etc., to achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Hydroisomerization Using a Sulfided SAPO Catalyst at 1,000 psig

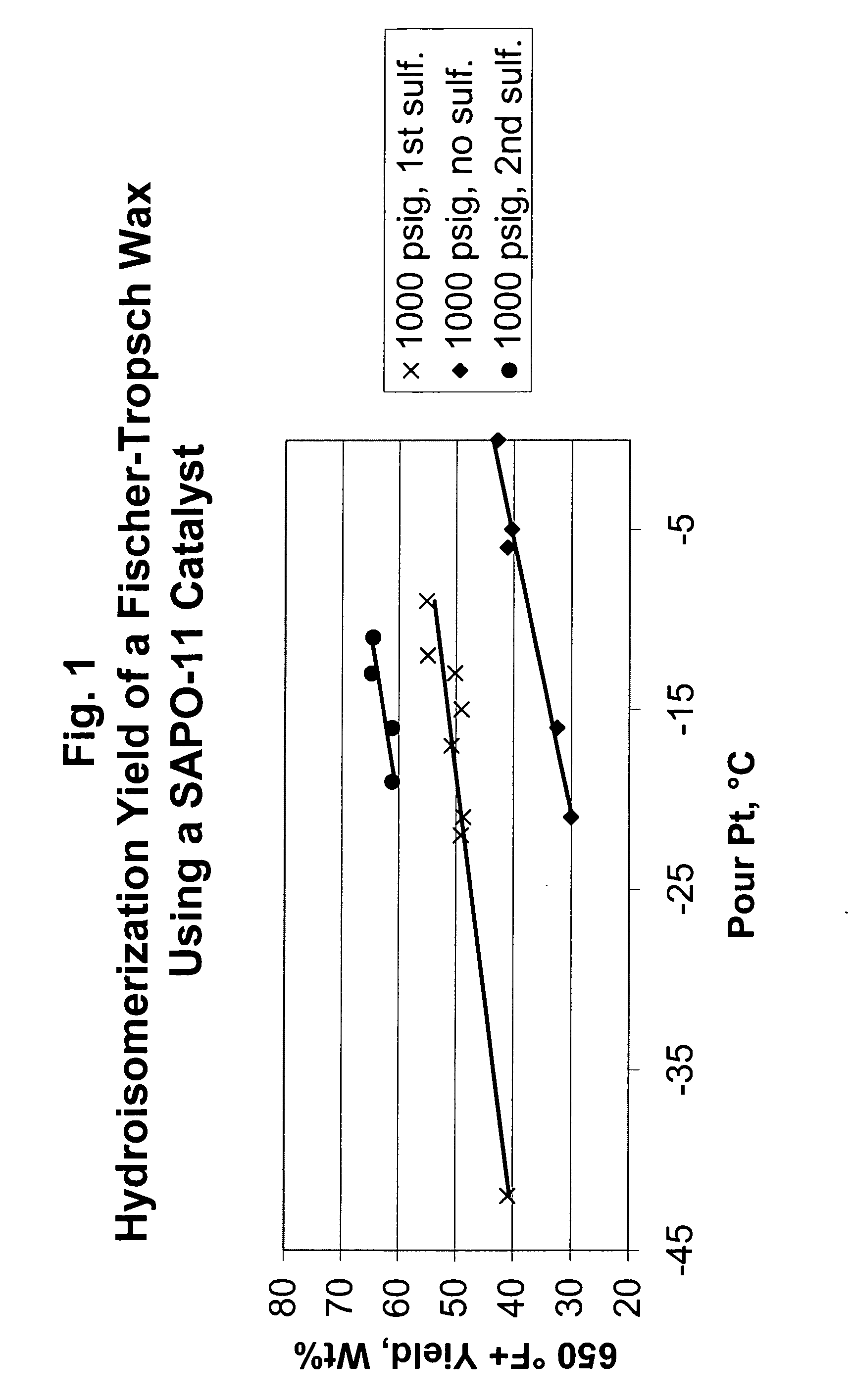

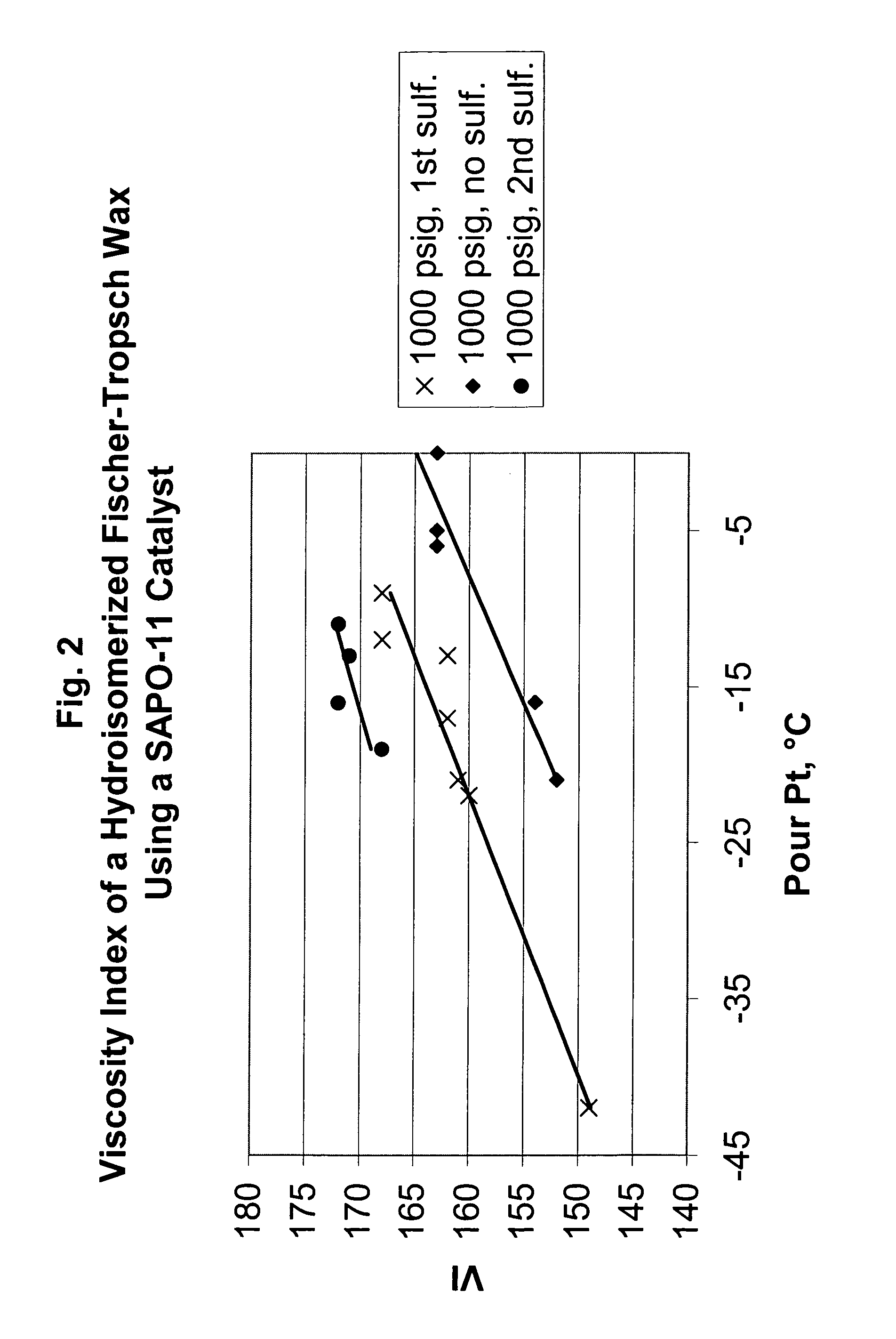

[0085] This example illustrates the effect of sulfiding a SAPO-11 catalyst. In FIG. 1, the 650° F.+yield (weight percent) obtained when a Fischer-Tropsch derived wax was hydroisomerized is plotted as a function of pour point (° C.) for three situations: 1) when the SAPO 11 catalyst is not sulfided prior to the hydroisomerization reaction, 2) when the catalyst was pre-sulfided, and 3) when the catalyst was re-sulfided after being on-stream for 2040 hours. Each of the three experiments was conducted at a hydrogen partial pressure of 1,000 psig.

[0086] For comparative purposes, data points at a pour point of about −15° C. may be considered. The 650° F.+yield for the un-sulfided catalyst was about 32 weight percent, which increased to a yield of about 50 weight percent when the catalyst was pre-sulfided, representing an increase of about 18 weight percent. After re-sulfiding the catalyst, the yield increased an additional 1...

example 2

Hydroisomerization Using a Sulfided SAPO Catalyst at Varying Pressures

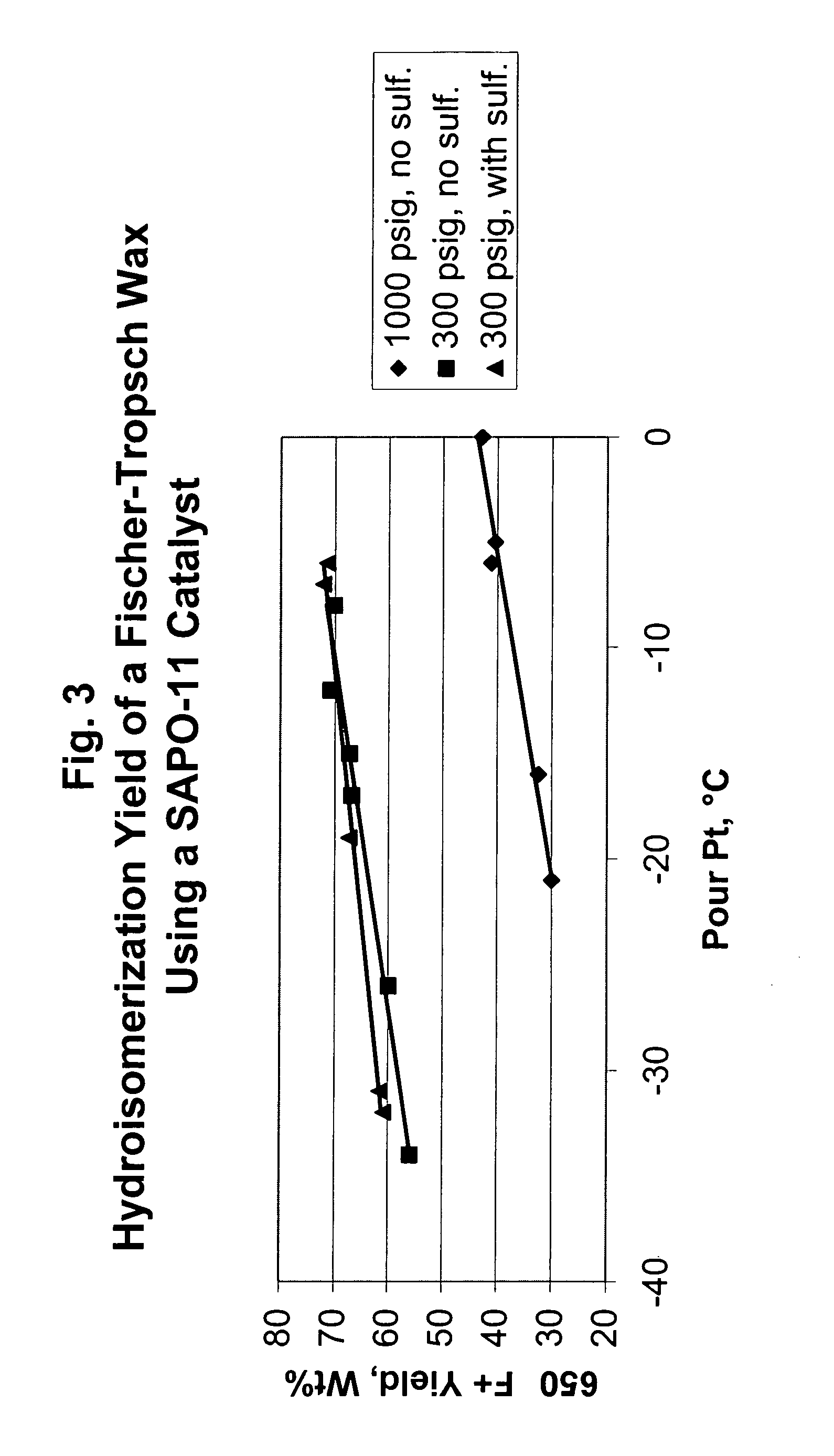

[0088] The effects of sulfiding at two different pressures (and the effects of pressure without sulfiding), are shown in FIGS. 3 and 4. The 1,000 psig curves in FIGS. 3 and 4 are the same as those in FIGS. 1 and 2; in other words, the 1,000 psig data has simply been re-plotted. Decreasing the hydrogen partial pressure from 1,000 to 300 psig during hydroisomerization results in a 650° F.+yield increase from about 35 to 68 weight percent, and an increase in viscosity index of about 155 to 168. Thus, this example shows that hydroisomerization yield and viscosity index are both enhanced as the hydroisomerization pressure is decreased.

[0089] Additionally, comparing FIGS. 1 and 2 with FIGS. 3 and 4 illustrate that sulfiding a SAPO-11 had a larger beneficial effect at higher pressures (e.g., 1,000 psig) than at lower pressures (e.g., 300 psig). Sulfiding the SAPO-11 catalyst had a modest effect on 650° F.+yield at 300 ...

example 3

Hydroisomerization Using a Sulfided Zeolite Catalyst

[0090] This example was conducted as described for Example 1, but using SSZ-32 as the catalyst. FIG. 5 shows that the 650° F.+yield (weight percent) from Fischer-Tropsch wax hydroisomerized at 1,000 psig for both sulfided and un-sulfided SSZ-32 catalysts. The yield was about 55 (at a pour point of −15° C.). Likewise, the viscosity index was about 175.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com