Method of brazing aluminum products and furnace therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

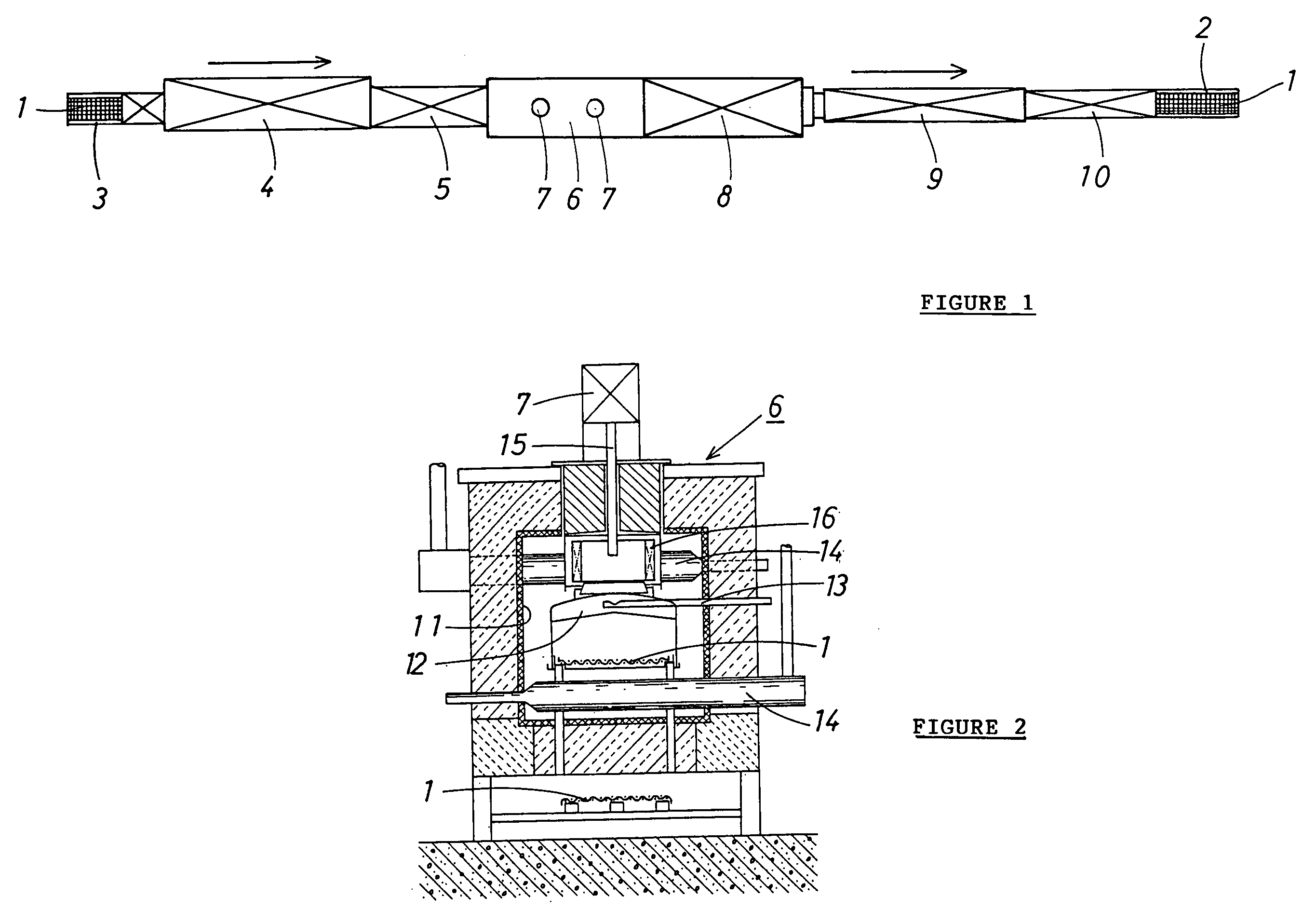

[0022] Heat exchangers made from aluminium and of 0.5 Kg each were fixed by jigs of 2 Kg, and three of these aluminium products were aligned in a line along a direction which is transverse to the driving direction of the mesh belt. Such lines were successively placed on the mesh belt 1, whereby they were sent into the aforementioned continuous atmosphere furnace. Those portions of the aluminium products which were to be brazed, had been applied by NOCOLOK flux (a trade name of Alcan Co.) made from fluoric compounds having a melting point of 540° C. and also by an Al—Si system solder having a melting point of 585° C.

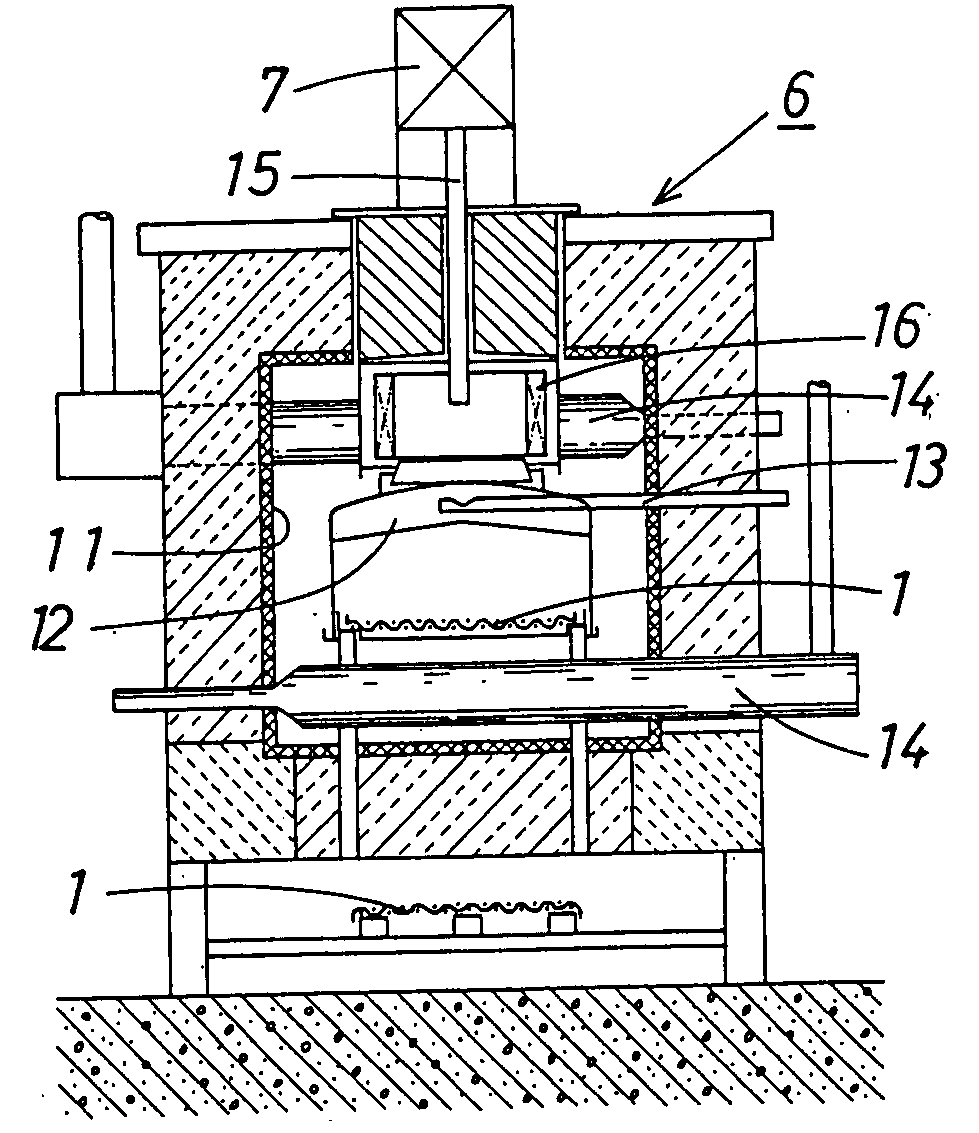

[0023] A nitrogen gas which was introduced by the pipe 13 within the furnace inner walls 11 of the preheating furnace having a rectangular cross section, was heated by the radiant tubes 14 and agitated by the blades 16 of the fan 15, whereby it made convection currents within the furnace inner walls and heated the aluminium products which were sent into the preheating fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com