Electrolytic method for photoresist stripping

a technology of photoresist stripping and electrolysis method, which is applied in the field of wet processing, can solve the problems of affecting the ability to remove the photoresist, affecting the removal ability of the photoresist, and presenting environmental concerns for the removal of the photoresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

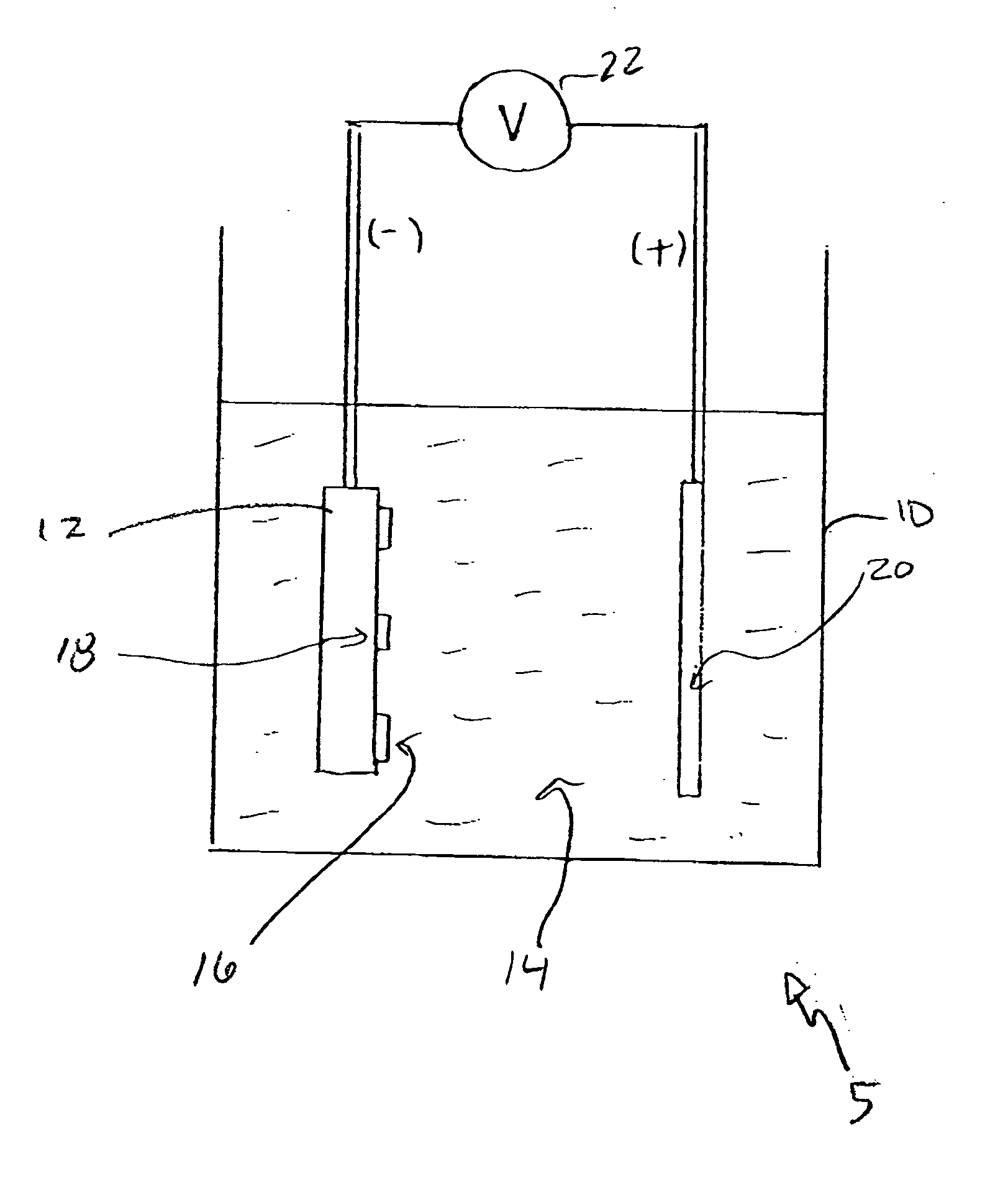

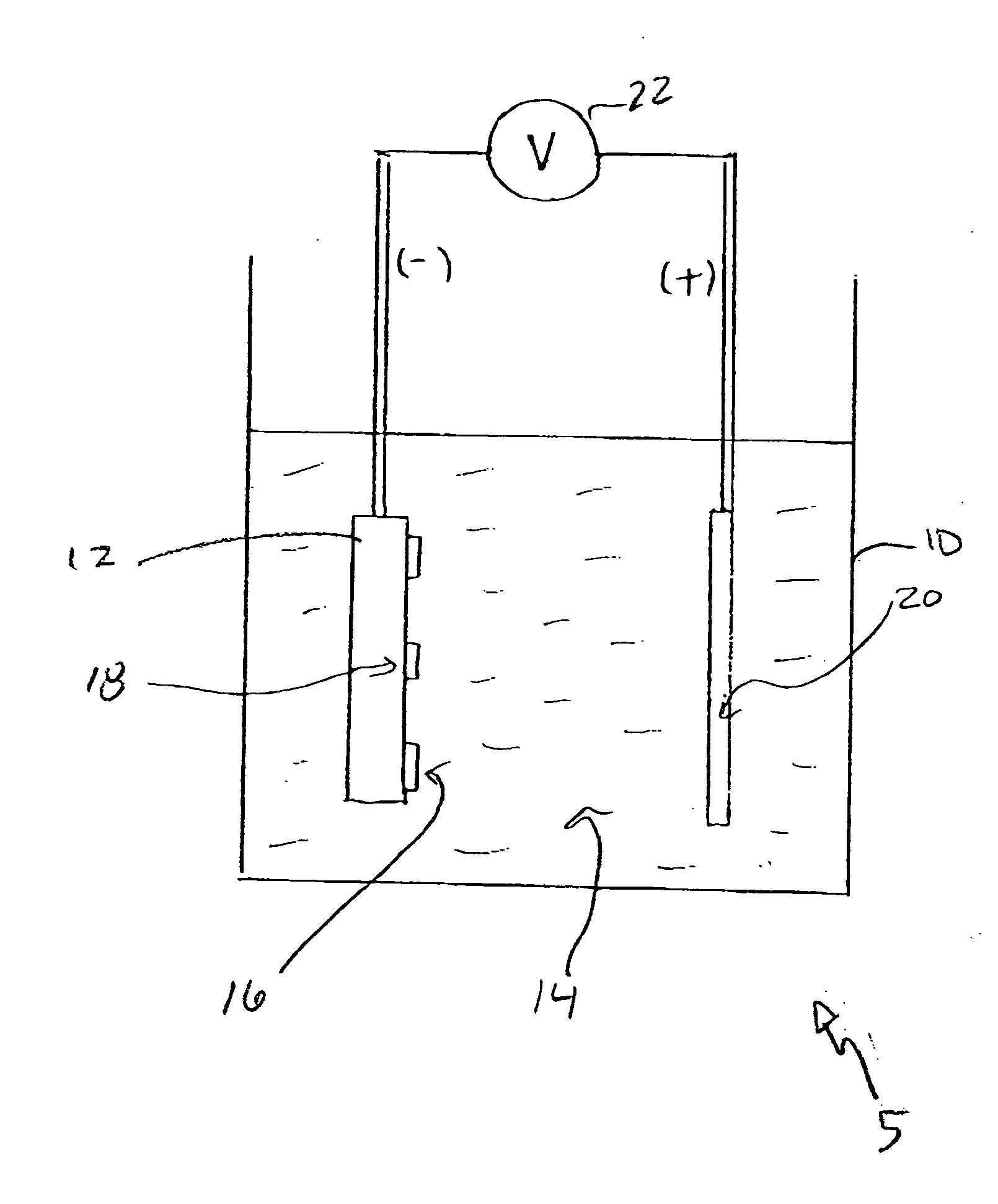

[0020] In describing the preferred embodiment of the present invention, reference will be made herein to FIG. 1 of the drawings in which like numerals refer to like features of the invention.

[0021]FIG. 1 depicts an apparatus for stripping a photoresist. An electrolytic cell 5 is used for electrolytic stripping of a photoresist. A piecepart 12 is placed in a tank 10 containing a bath of neutral electrolytic solution 14. The piecepart 12 includes photoresist material 16 on a conductive surface 18. Also immersed in the bath is a counter electrode 20. A voltage potential is applied across the conductive surface 18 and the counter electrode 20 by a power supply 22. Photoresist stripping from the conductive surface 18 is performed in the electrolytic cell 5 with the neutral electrolyte 14, such as sodium citrate, sodium orthophosphate, sodium sulfate, sodium nitrate, ammonium acetate, sodium acetate, or with other non-aggressive, water based ionic conductive chemical. Importantly, a che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com