Method and apparatus for perimeter cleaning in cold hearth refining

a technology of cold hearth and perimeter cleaning, which is applied in the field of cold hearth melting and refining apparatus and processes, can solve problems such as choking the flow of liquid stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

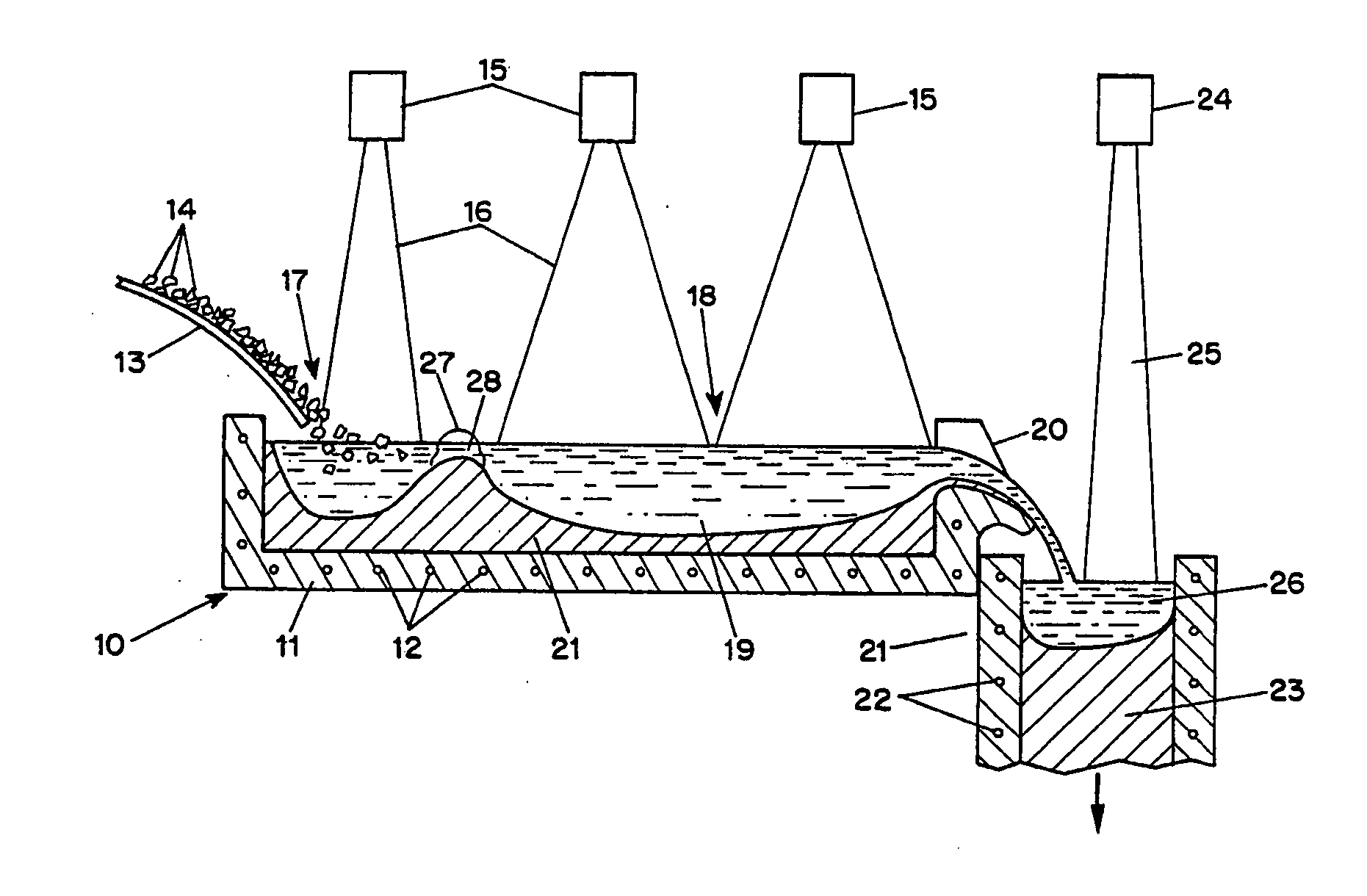

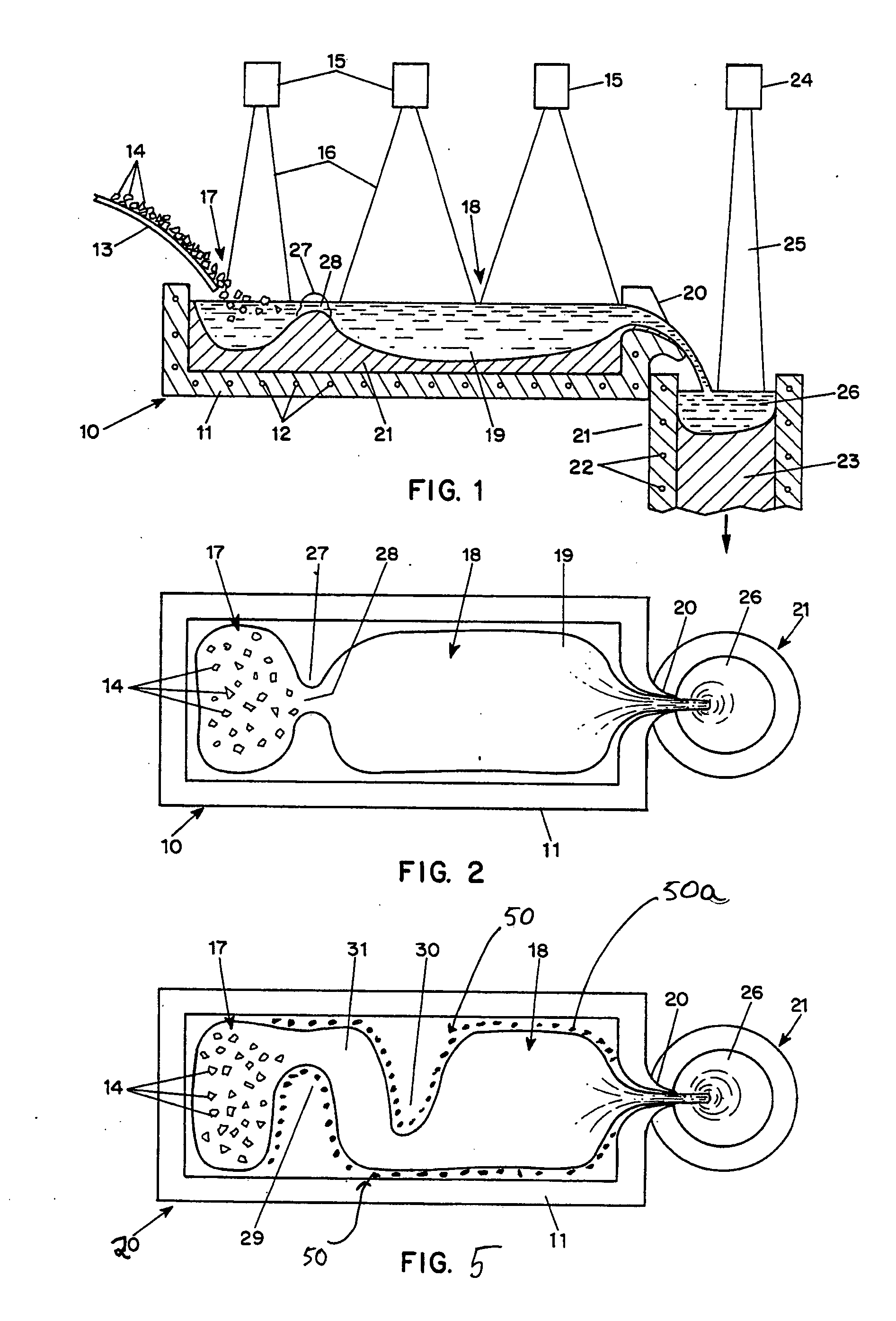

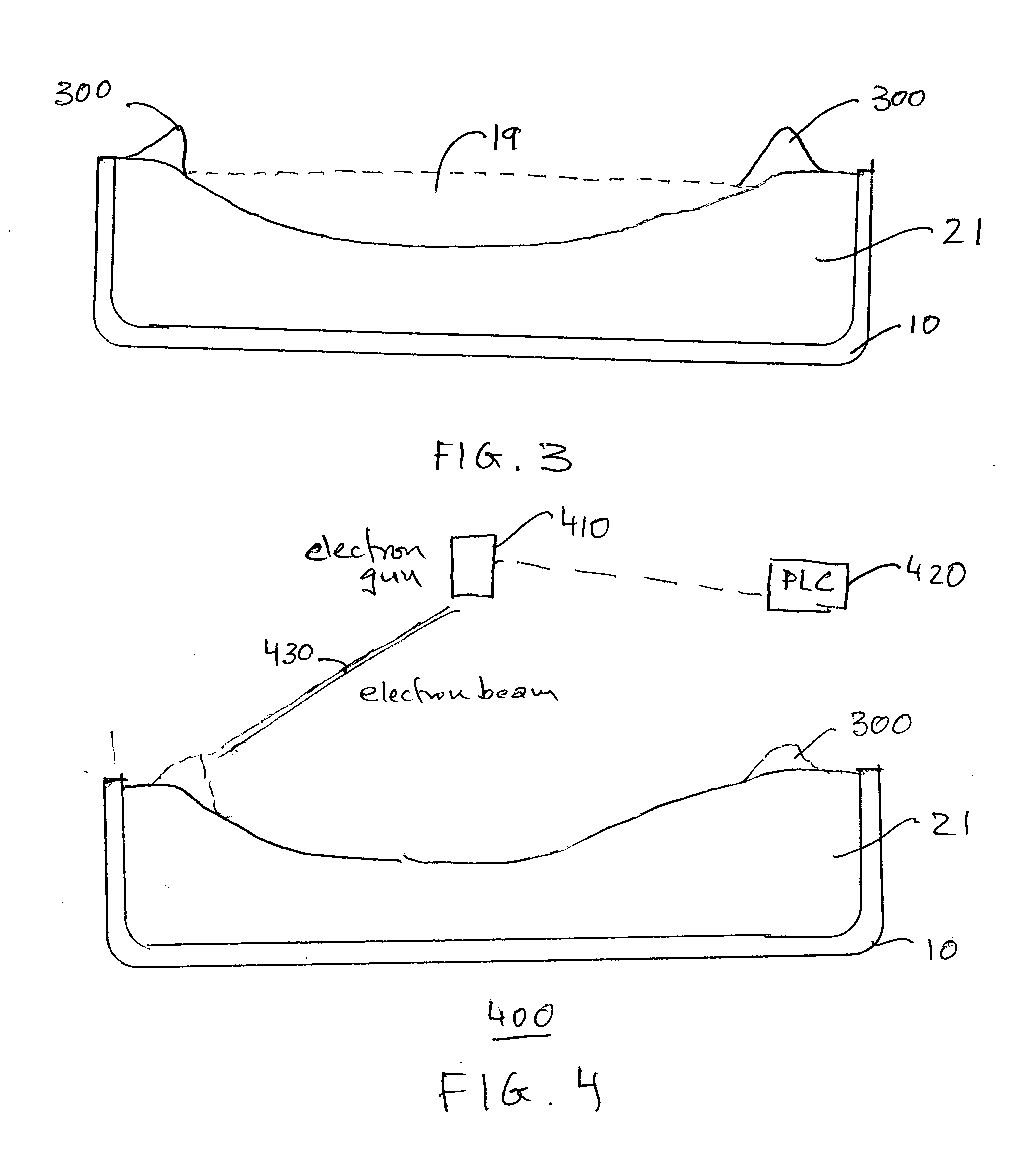

[0015] The present disclosure provides solutions for improved electron beam cold hearth melting and refining operations. A disclosed solution concerns cleaning the perimeter of the liquid stream of molten material that flows through the cold hearth.

[0016] The invention is suitable for improving the operation of EBCHR hearths, whose configurations may vary, for example, based on considerations of the type of material to the refined, throughput and other manufacturing parameters. Exemplary hearths, which can be used for refining titanium alloys, are described in Harker U.S. Pat. Nos. 4,932,635 and 4,961,776 (hereinafter “Harker”). In order that the invention herein described may be easily understood, the subsequent description is set forth with reference to the prior art cold hearths described by Harker. It will, however, be understood that the invention is equally applicable to other types or configurations of cold hearths. As an aid to the understanding of the present invention, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time period | aaaaa | aaaaa |

| dwell time | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com