Single column extendable draft offshore platform

a floating platform and single column technology, applied in the field of floating vessels, can solve the problems of increasing the complexity of floating platforms, limiting the operation of fixed platforms, and affecting the operation efficiency of floating platforms, so as to reduce the resistance to surface level wind, and reduce the cost of floating platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

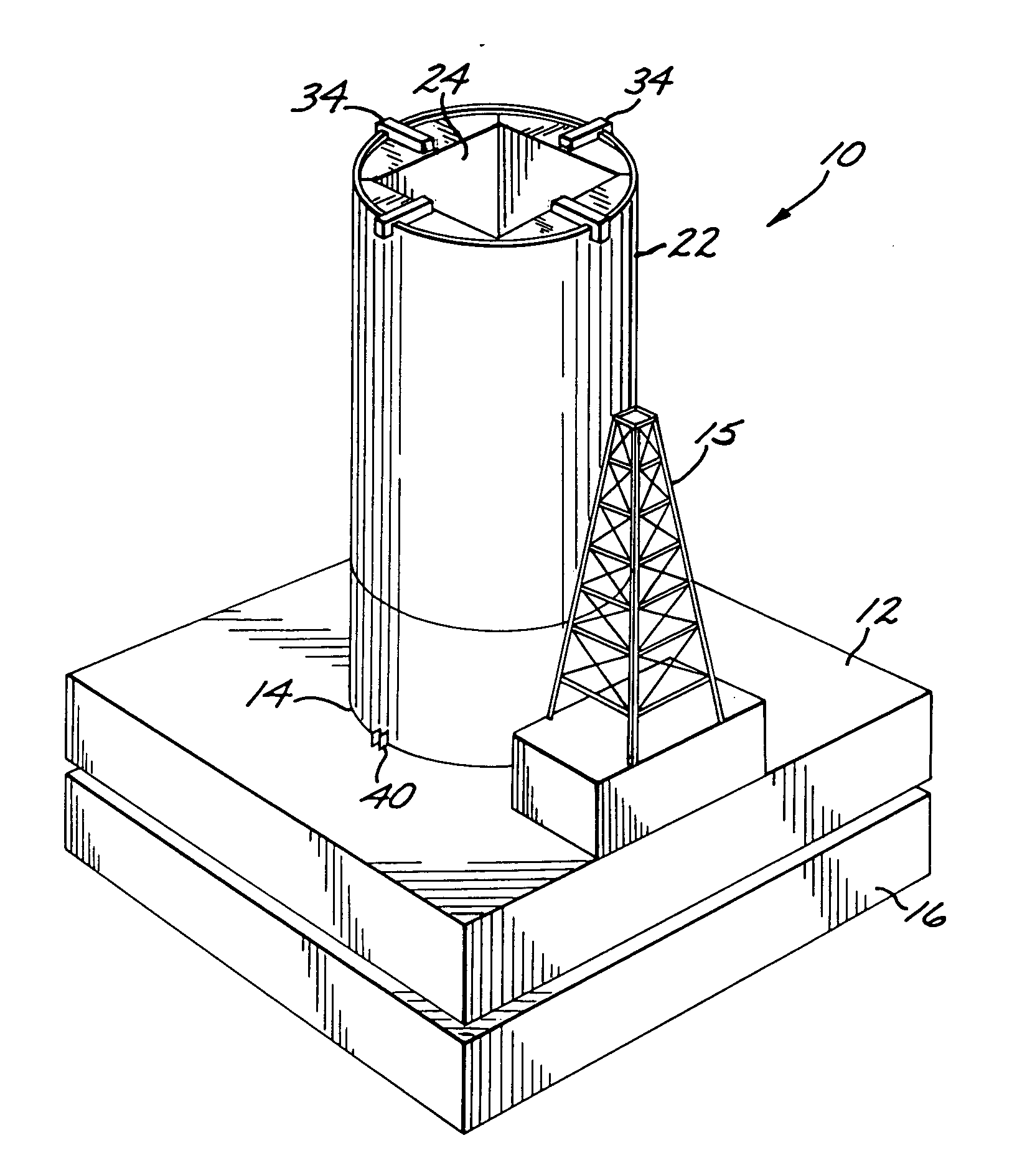

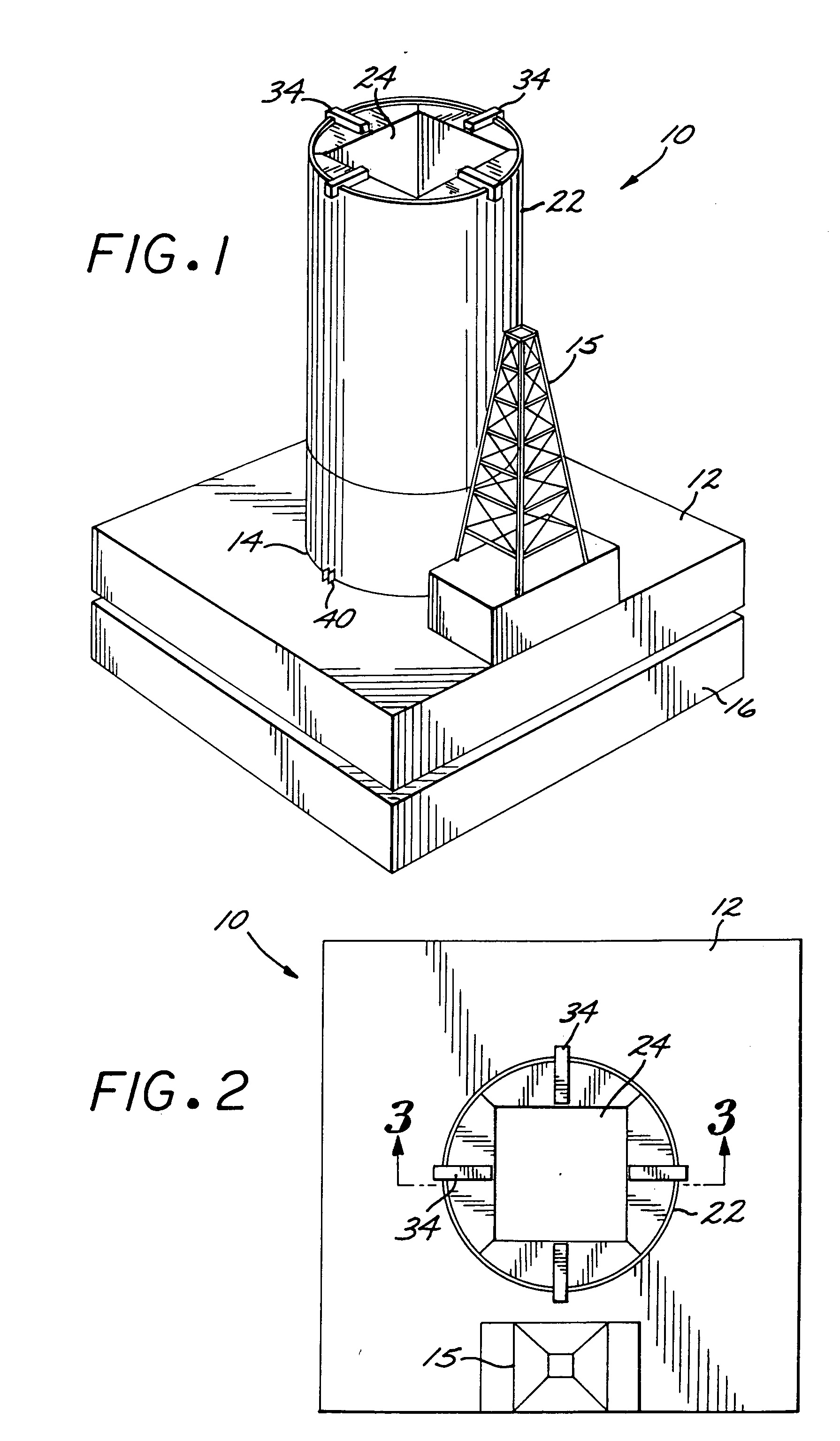

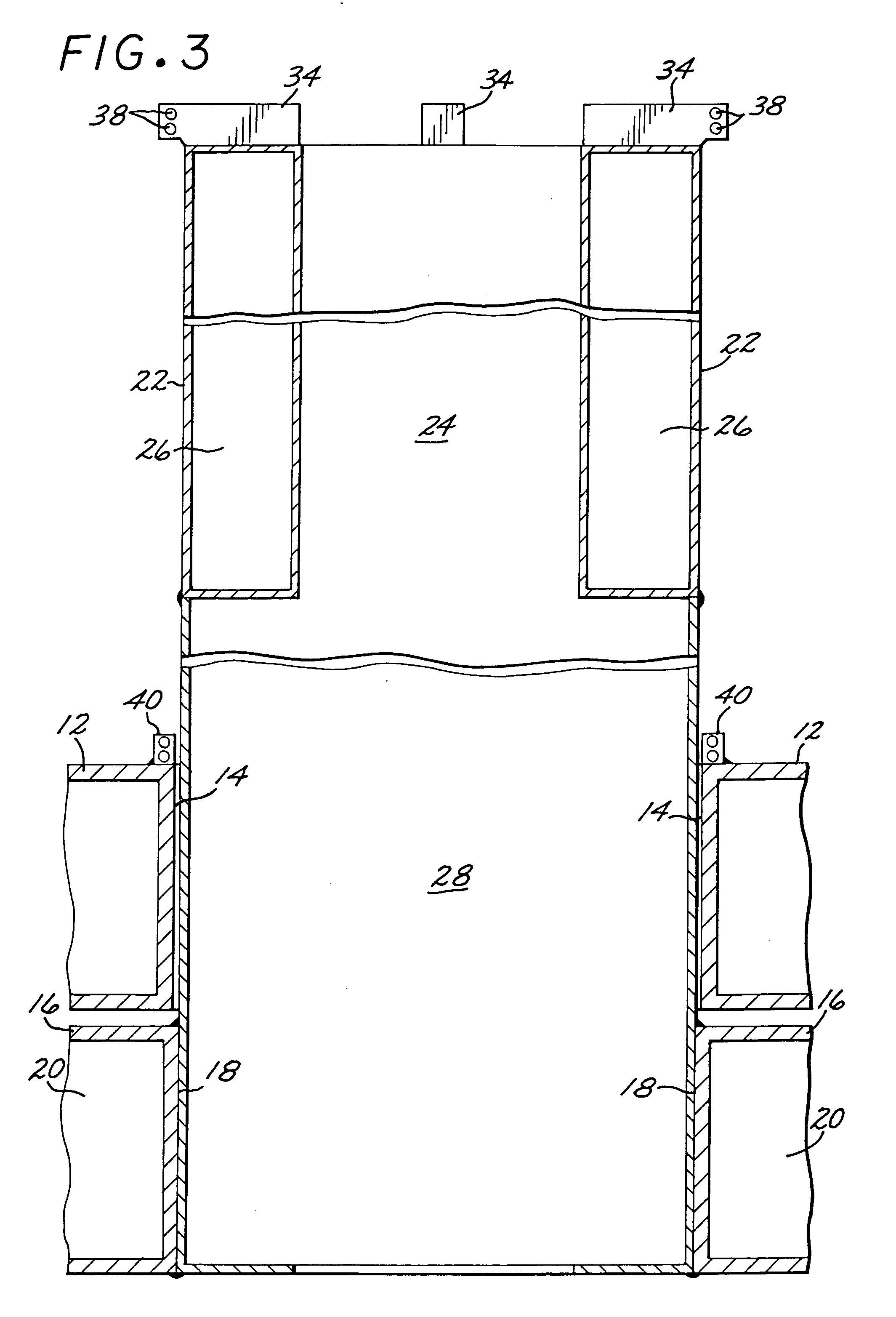

[0034] An exemplary single column extendable draft offshore oil and gas drilling and production platform (“EDP”) 10 in accordance with the present invention is illustrated in the perspective and top plan views of FIGS. 1 and 2, respectively. As illustrated in the figures, the EDP comprises a buoyant “topside,” or equipment deck12, having an opening 14 at its center. The deck may be rectangular or square in its plan view, in the manner of a conventional barge, but may have other shapes as well, including triangular, or octagonal, depending on the particular application. In the particular embodiment illustrated in FIGS. 1 and 2, a derrick and associated draw works 15 are shown slidably disposed on the upper surface of the equipment deck, e.g., on tracks or rails (not illustrated), for movement between a first, or working, position over the central opening 14 of the deck, and a second, or idle, position horizontally displaced from the first position, to enable the single support column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com