Castable aluminum alloy

a technology of aluminum alloy and cast aluminum, which is applied in the field of castable aluminum alloy to achieve the effects of reducing porosity, high strength, and less cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

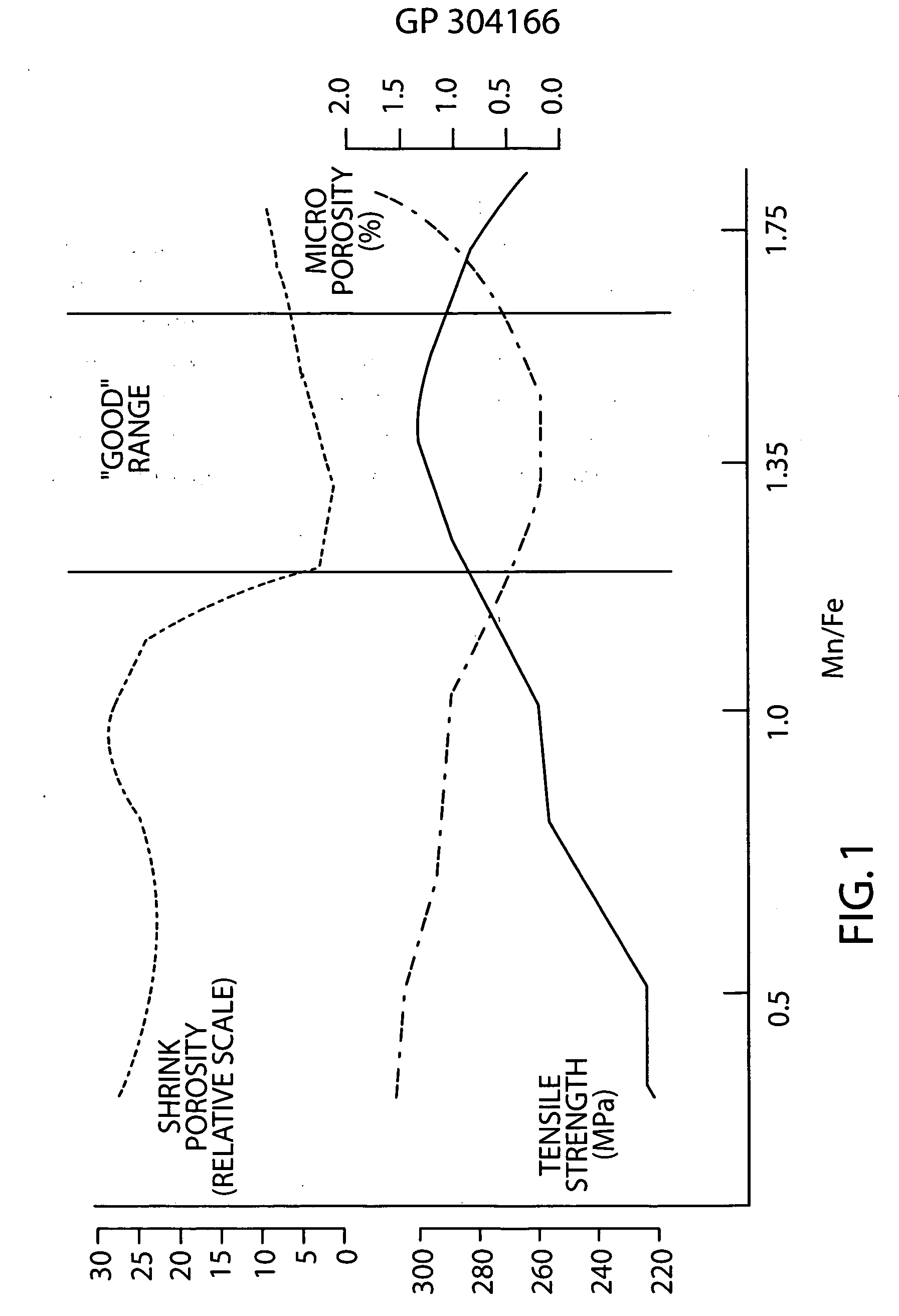

[0036]FIG. 1 is a schematic representation of the effect of the Mn / Fe weight ratio on shrink porosity, microporosity, and tensile strength of a Cu-containing aluminum alloy having a composition, in weight %, 6.5% Si, 3.5% Cu, 0.4% Mg, 0.5% Fe, Mn as specified, and balance Al. The effect of Mn / Fe was determined by preparing a master heat of the base composition and cast into 30 pound ingots. For each value of Mn / Fe weight ratio tested in a series of Mn / Fe ratios from 0.1 to 2.0, a separate heat was prepared and Mn added in the form of Al—25 weight % Mn master alloys. In addition, pure Al was added to each of the heats except to the heat with the highest Mn / Fe ratio. This procedure was used to insure the total addition (Al—25Mn master alloy+pure Al) was a constant to dilute all of the other alloying elements by a constant amount. After melting in a clay-graphite crucible in air, each heat was degassed using a commercial rotary degasser with argon. Two sand molds were made for each hea...

example 2

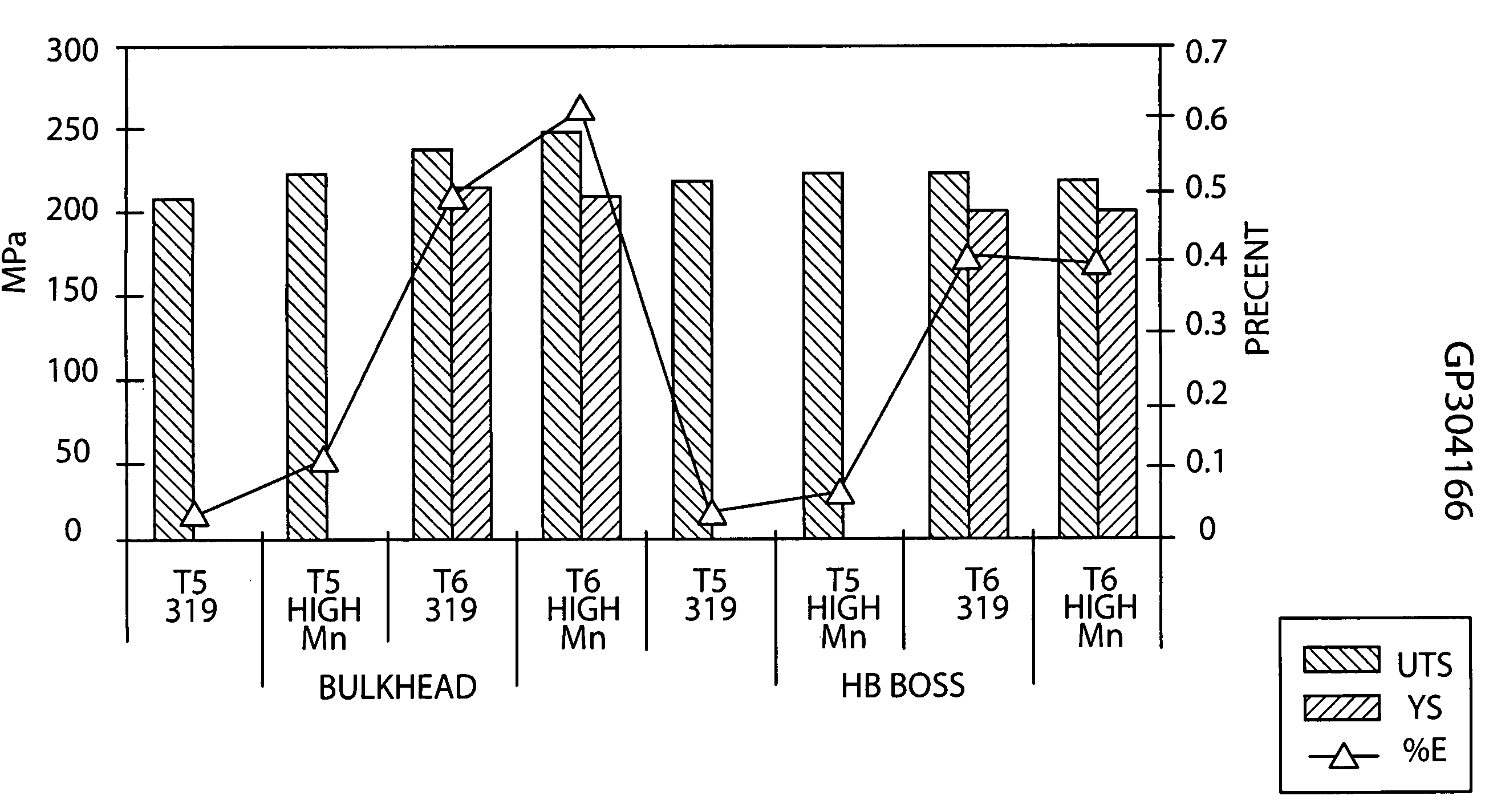

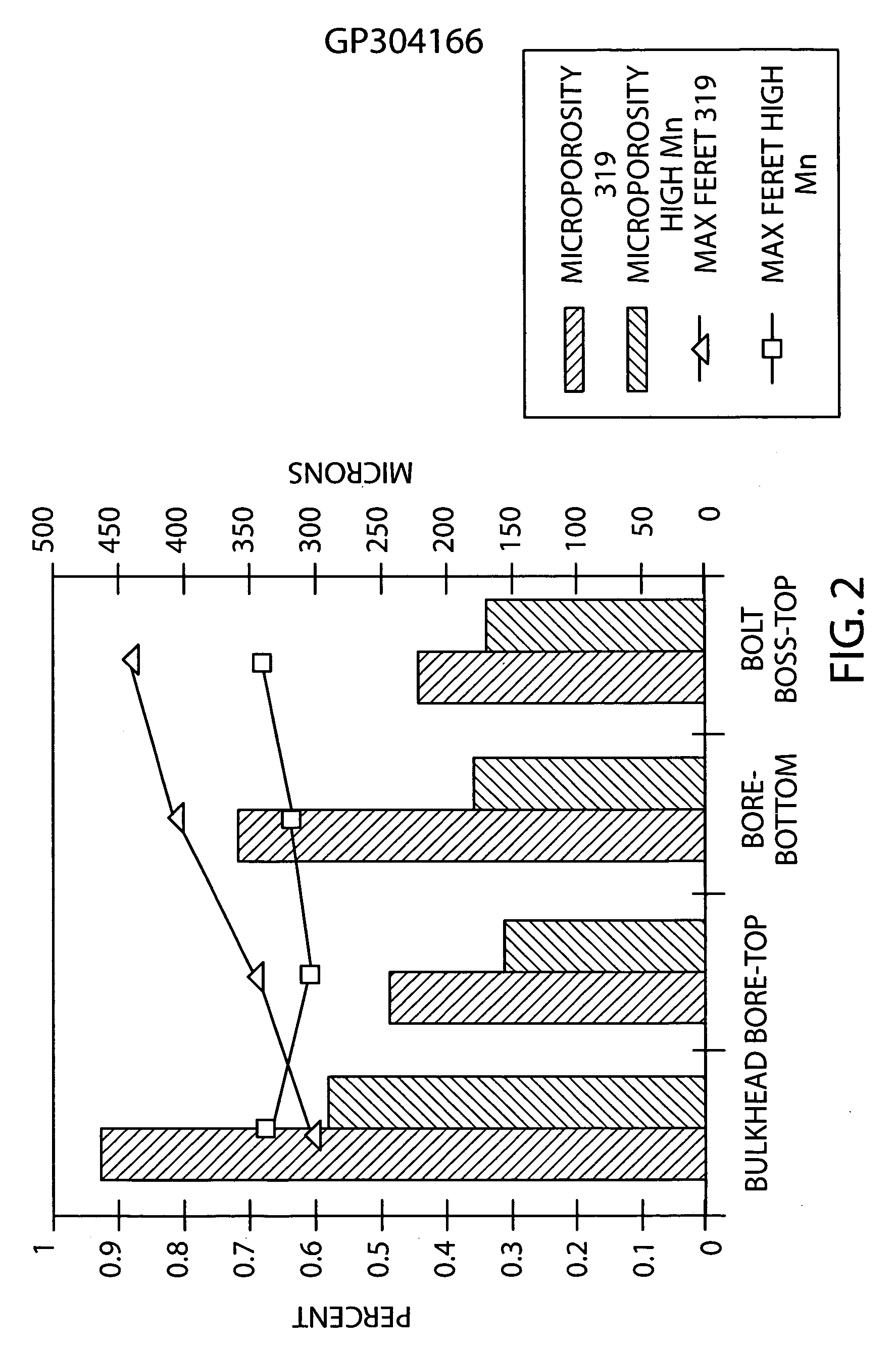

[0039]FIGS. 2 and 3 illustrate practice of the invention with respect to an illustrative castable Cu-containing aluminum alloy.

[0040] In particular, FIG. 2 is a graph of showing the effect of Mn / Fe weight ratio on casting porosity at four different locations of cylinder blocks cast using the lost foam casting process. A Cu-containing aluminum alloy (319 alloy) having a composition, in weight %, 7% Si, 3.5% Cu, 0.55 Fe, 0.75% Mn, and balance Al providing a Mn / Fe weight ratio of 1.33 pursuant to the invention was cast at a melt temperature of 1430 degrees F. into a lost foam mold. The alloy was solidified in the mold at a cooling rate of about 10 degrees F / minute. For comparison, the same Cu-containing alloy with Mn of only 0.35 weight % providing a Mn / Fe weight ratio of only 0.64 was similarly cast and solidified in a lost foam mold. The Mn / Fe ratio of 0.64 is in excess of usually recommended levels but nevertheless practiced at certain commercial foundries for such alloy.

[0041] Th...

example 3

[0046] This example involves beneficial effects achieved by controlling the Mn / Fe weight ratio for aluminum alloys having silicon contents in the range of 11 to 12 weight % of the alloy. For example, FIG. 4 illustrates effects achieved with respect to castable Cu-containing aluminum alloys having a composition, in weight %, 11.75% Si, 0.4% Fe, 3.6% Cu, 0.15% Mg, 0.03% Sr, Mn as specified, and balance Al. The alloys were cast at a melt temperature of 1320 degrees F. into bonded sand molds. The alloys were solidified in the molds at a cooling rate of about 10 degrees F. / minute to produce cast bars that were heat treated to the T6 condition and then cut to make round tensile bars for testing.

[0047]FIG. 4 illustrates a significant increase in UTS of the heat treated specimens achieved by controlling the Mn / Fe weight ratio above 0.74, especially at a ratio of 1.367. The tensile elongation decreased somewhat at Mn / Fe ratios of 0.74 and 1.14 and then increased significantly at a Mn / Fe rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com