Semiconductor device and method of fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

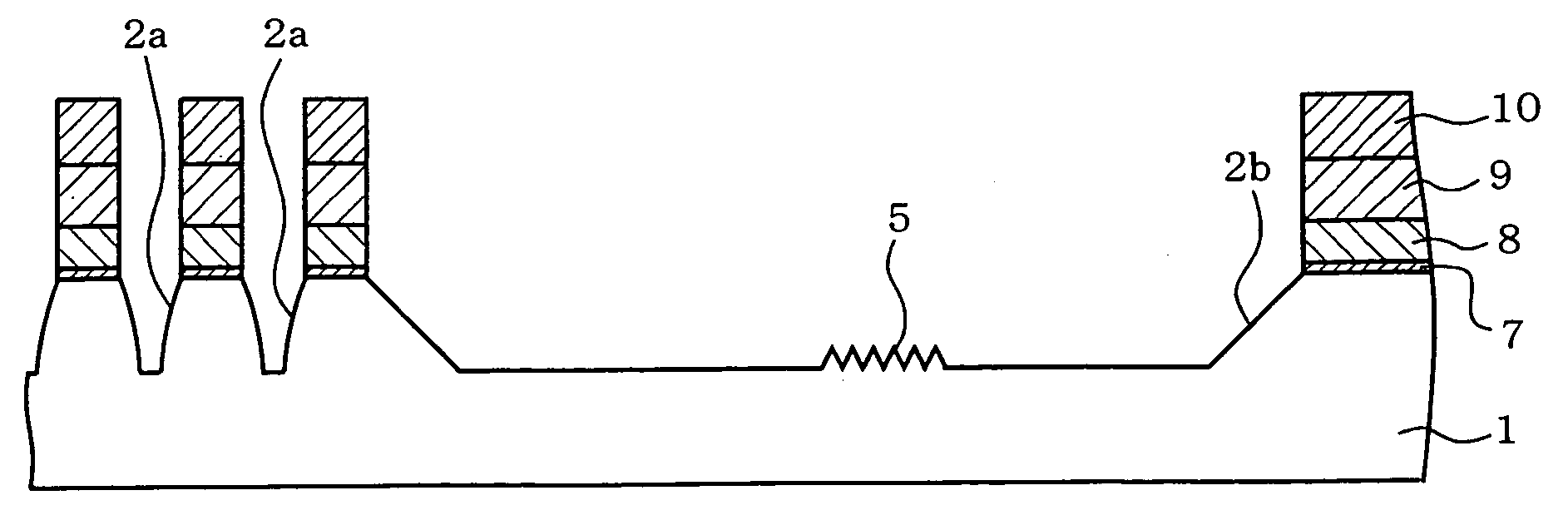

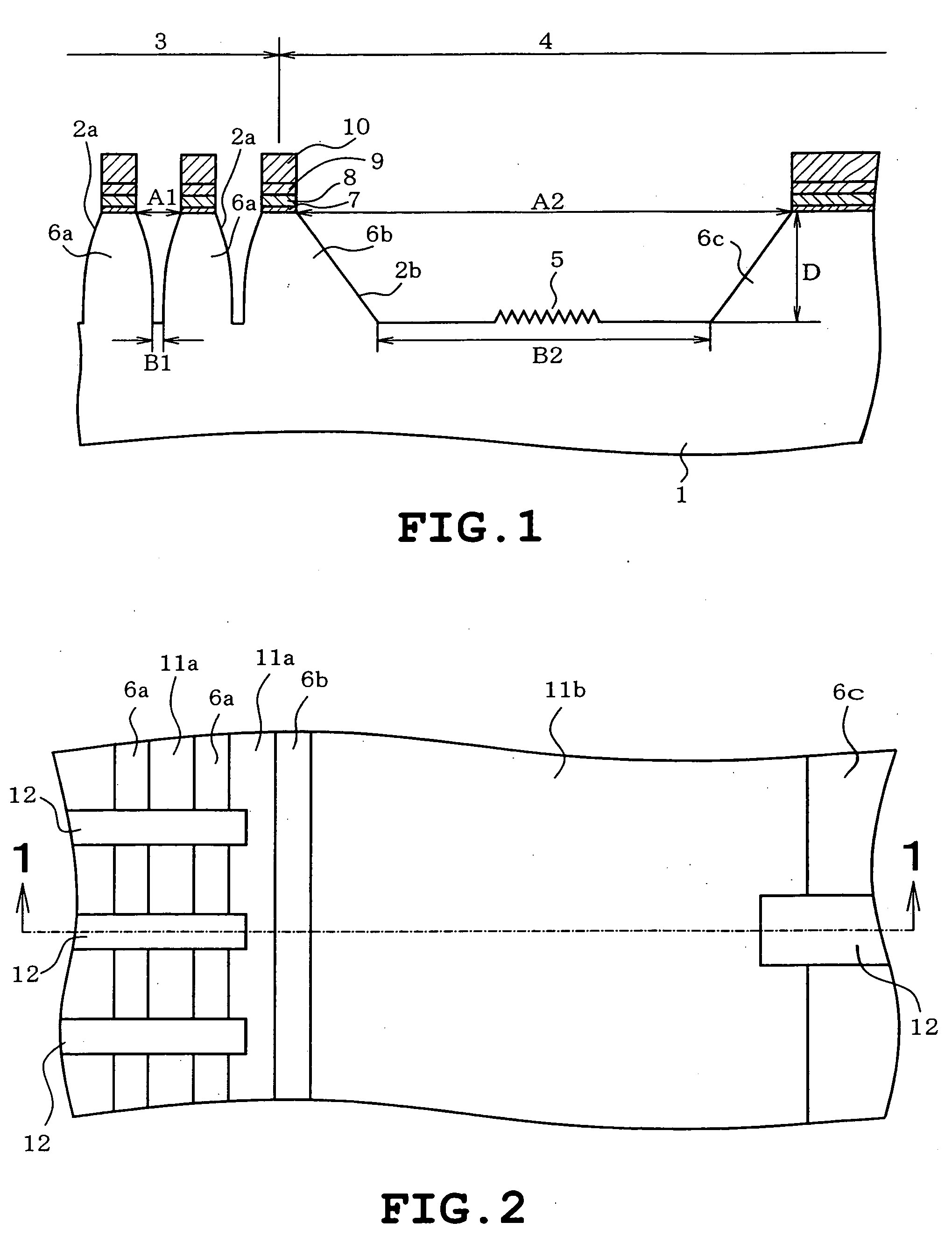

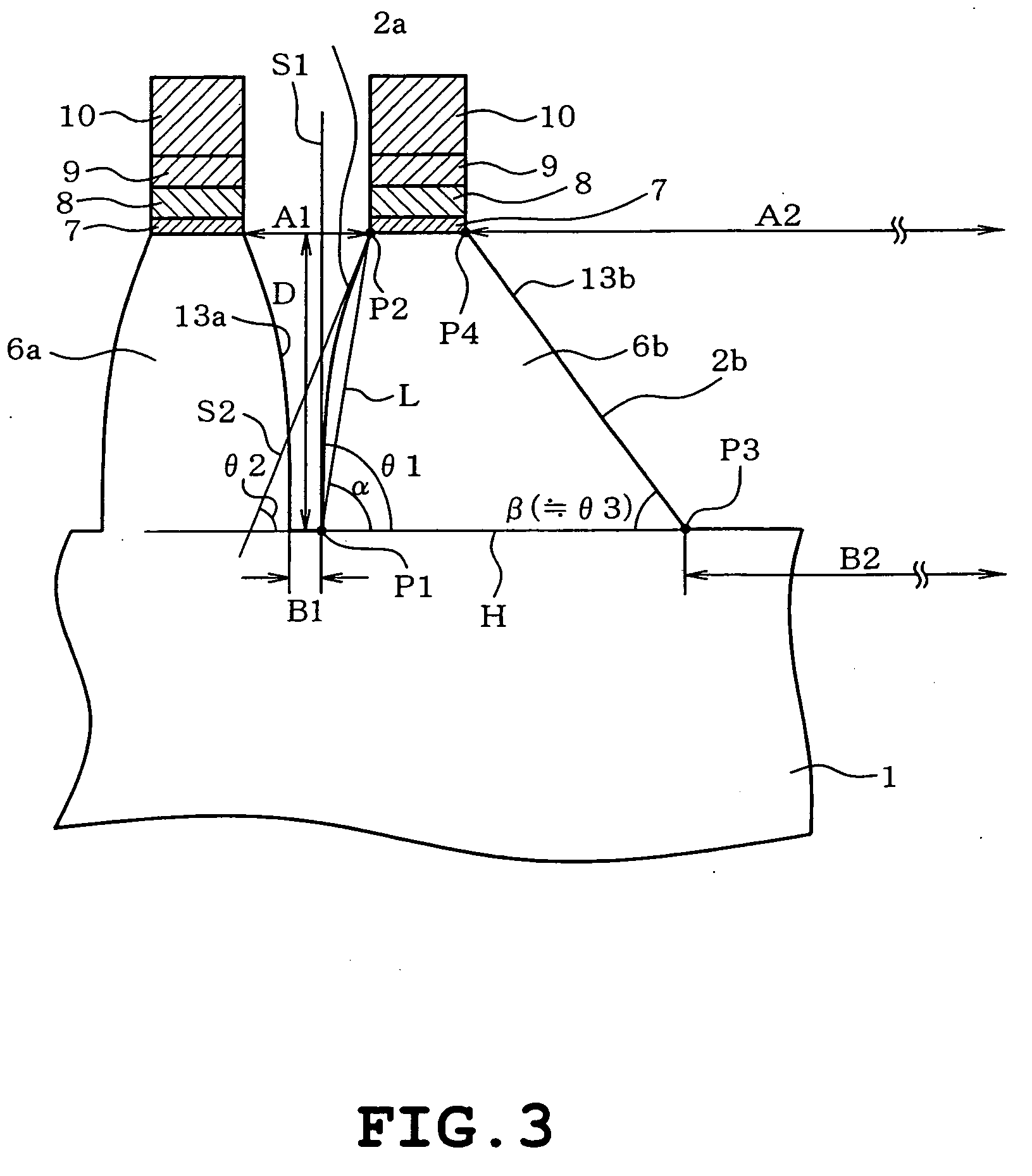

[0023] One embodiment of the present invention will be described with reference to the accompanying drawings. The invention is applied to a flash memory which is one type of non-volatile memory. Referring to FIG. 1, the state of the semiconductor device after execution of a trench forming process is shown. FIG. 2 shows a control gate electrode. FIG. 1 is a sectional view taken along line 1-1 in FIG. 2. Chips composing the flash memory each include a memory cell region in which a number of memory cells are formed and a peripheral circuit region in which peripheral circuits for driving the memory cells are formed.

[0024] A silicon substrate 1 serving as a semiconductor substrate has trenches 2a and 2b for forming element isolation regions. The trenches 2a and 2b have opening widths A1 and A2 respectively and the same depth D as each other. The trench 2a has a higher aspect ratio R1 (D / A1) so as to correspond to a memory cell region 3, whereas the trench 2b has a lower aspect ratio R2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com