Process for improving water-whitening resistance of pressure sensitive adhesives

a technology water-whitening resistance, which is applied in the direction of adhesives, adhesive additives, ester polymer adhesives, etc., can solve the problems that none of the above patents/publications disclose the preparation of pressure sensitive adhesives, and achieve the effect of improving the resistance to water-whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

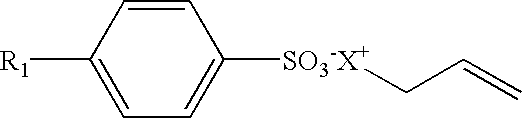

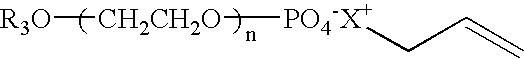

[0068] In a 2L jacketed glass reactor equipped with a reflux condenser, thermocouple and twin blade agitator, a poly(acrylate-co-styrene) latex was prepared. Monomer pre-emulsion was prepared by mixing 122.8 g water, 307.34 g 2-EHA, 70 g S, 65.68 g MA, 9.56 g MAA, and 13.4 g AA with 4.28 g Hitenol KH-05. The reactor was charged with 296.72 g of water, 1.8 g PPS, and 1.47 g of Hitenol KH-05. Separately, 72.12 g of PPS stock solution (2.86 wt. % concentration) was prepared in water. The reactor was heated with water. When the temperature reached 78° C., 6 g of the PPS stock solution was added and the monomer pre-emulsion delay was started at a 3.03 g / min rate and continued for 200 minutes. The temperature was maintained at 83° C. and the polymerization charge agitated continuously at 240 rpm. Every 20 min, 6 g of the PPS stock solution was added to the reactor over a period of 220 minutes. After the final charge of the PPS stock solution was completed, the reactor temperature was rais...

example 2

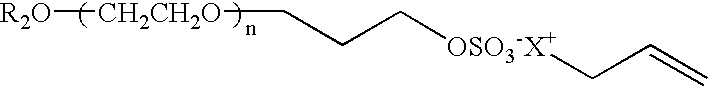

[0071] In a 2L jacketed glass reactor equipped with a reflux condenser, thermocouple and twin blade agitator, a poly(acrylate-co-styrene) latex was prepared. Monomer pre-emulsion was prepared by mixing 122.8 g water, 307.34 g 2-EHA, 70 g S, 65.68 g MA, 9.56 g MAA, and 13.4 g AA with 9.27 g Polystep NMS-7. The reactor was charged with 296.72 g of water, 1.8 g PPS, and 3 g of Polystep NMS-7. Separately, 72.12 g of PPS stock solution (2.86 wt. % concentration) was prepared in water. The reactor was heated with water. When the temperature reached 78° C., 6 g of the PPS stock solution was added and the monomer pre-emulsion delay was started at a 3.03 g / min rate and continued for 200 minutes. The temperature was maintained at 83° C. and the polymerization charge agitated continuously at 240 rpm. Every 20 min, 6 g of the PPS stock solution was added to the reactor over a period of 220 minutes. After the final charge of the PPS stock solution was completed, the reactor temperature was raise...

example 3

[0074] In a 2L jacketed glass reactor equipped with a reflux condenser, thermocouple and twin blade agitator, a poly(acrylate-co-styrene) latex was prepared. Monomer pre-emulsion was prepared by mixing 122.8 g water, 271.4 g 2-EHA, 116.5 g S, 57.55 g MA, 8.2 g MAA, and 12.35 g AA with 4.28 g Hitenol KH-05. The reactor was charged with 296.72 g of water, 1.8 g PPS, and 1.47 g of Hitenol KH-05. Separately, 72.12 g of PPS stock solution (2.86 wt. % concentration) was prepared in water. The reactor was heated with water. When the temperature reached 78° C., 6 g of the PPS stock solution was added and the monomer pre-emulsion delay was started at a 3.03 g / min rate and continued for 200 minutes. The temperature was maintained at 83° C. and the polymerization charge agitated continuously at 240 rpm. Every 20 min, 6 g of the PPS stock solution was added to the reactor over a period of 220 minutes. After the final charge of the PPS stock solution was completed, the reactor temperature was ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com