Production method of warm- or hot-formed product

a technology of hot-formed products and production methods, which is applied in the direction of heat treatment equipment, manufacturing tools, transportation and packaging, etc., can solve the problems of uneven strength of material caused by temperature differences, material tends to fracture during forming, and material is hardly formed, etc., to achieve good formability, good ductility, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[Example]

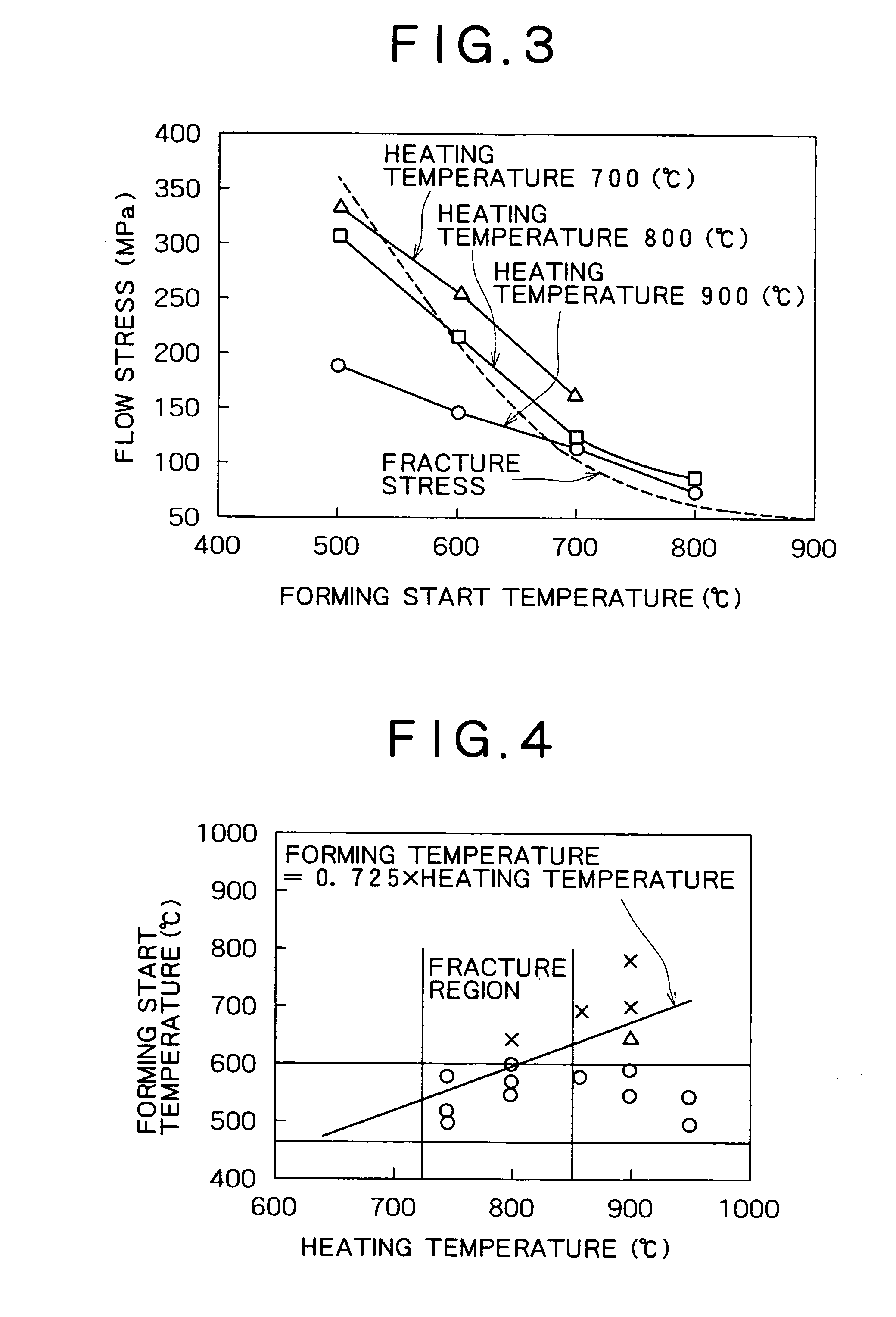

[0040] A steel having the chemical composition shown in Table 1 was rolled to a thickness of 1.4 mm and annealed by ordinary means. Round blanks 95 mm in diameter (blank diameter) were stamped from the rolled steel sheet and used for tests (the Ac1 and Ac3 transformation temperatures of the blanks were accordingly 725° C. and 850° C., respectively).

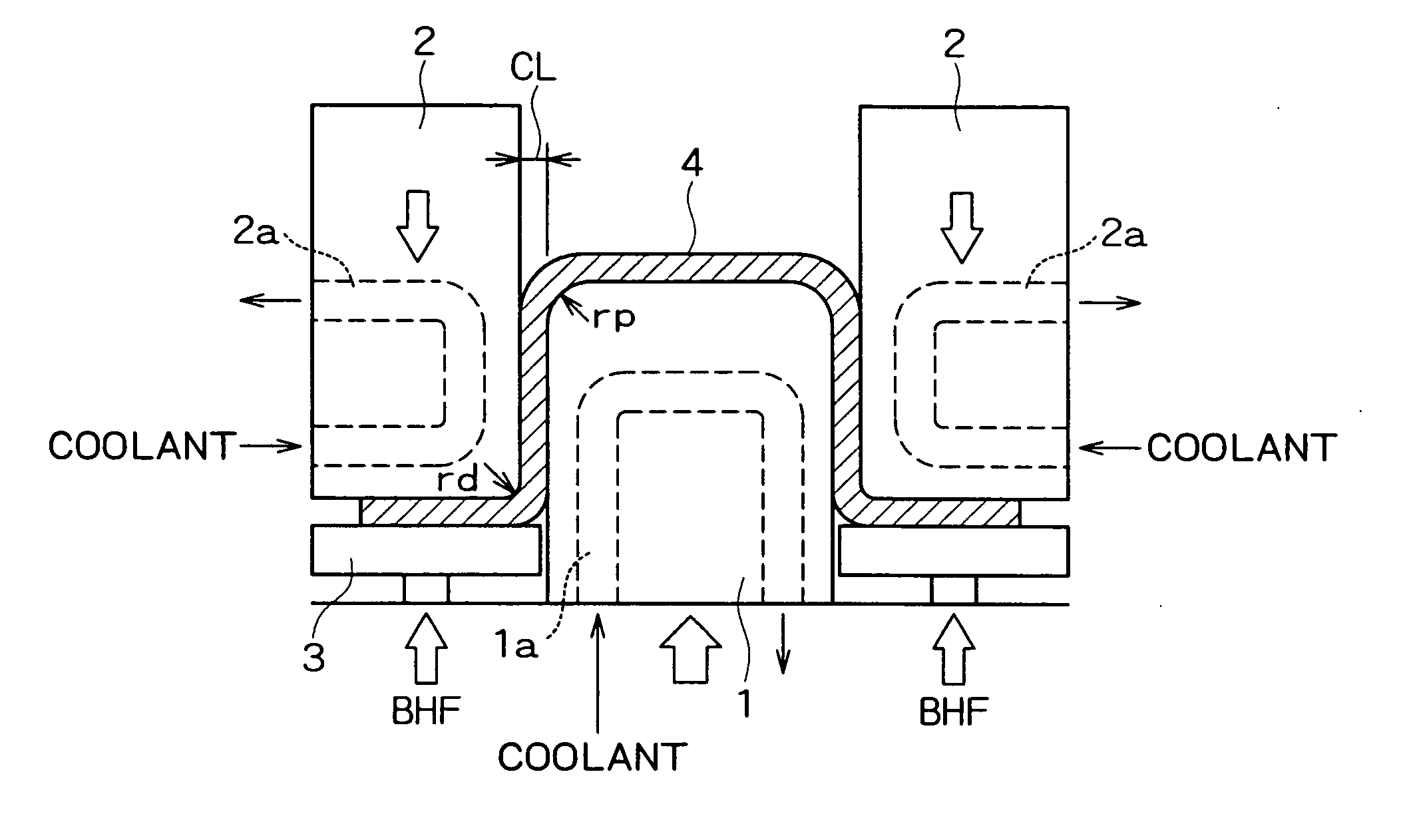

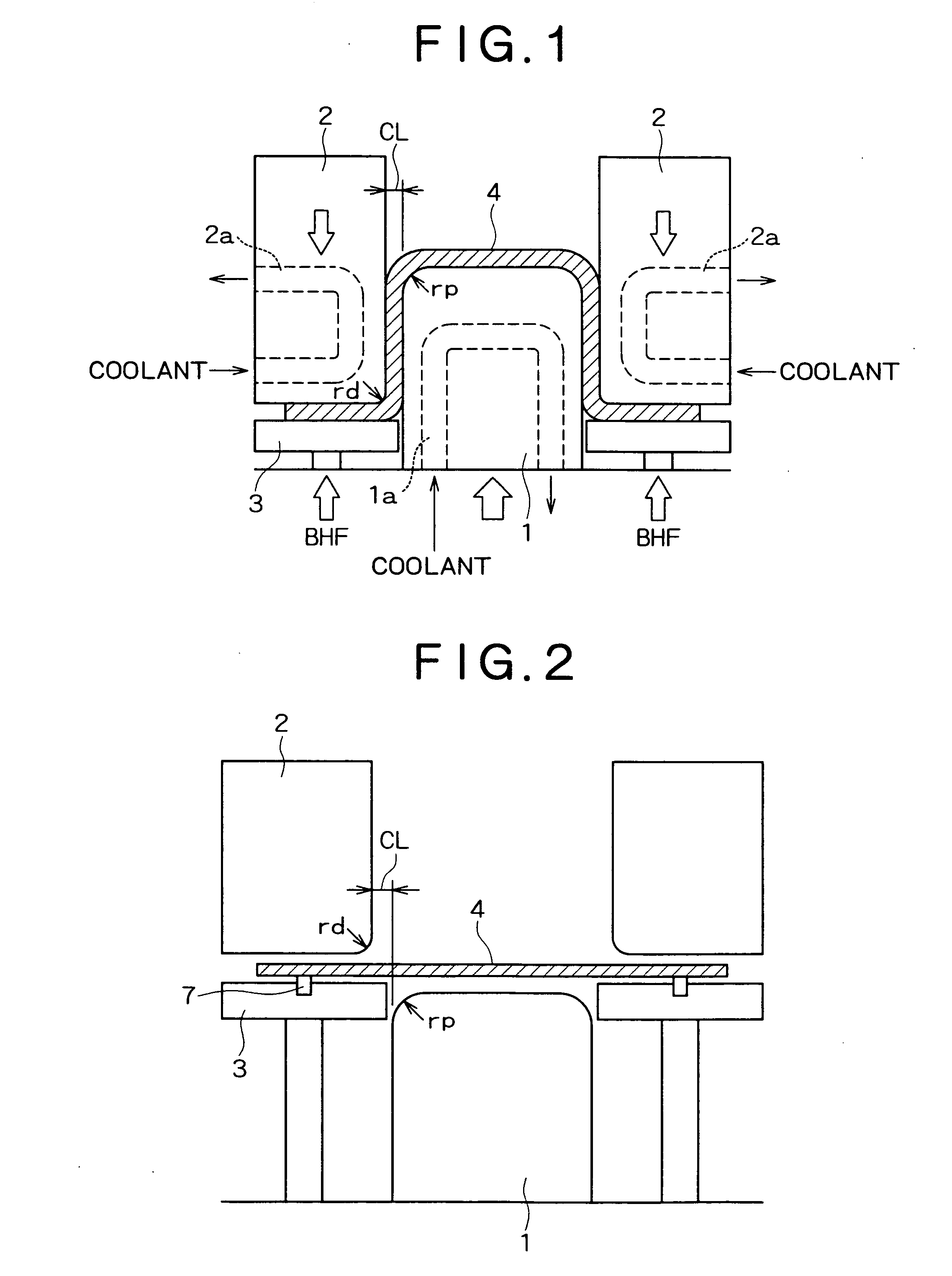

[0041] The round blanks were subjected to square-shell drawing while it was warm or hot with a tool set having a square-shaped punch head (the tool set comprising a rectangular die and a rectangular punch and the length of each side being 45 mm, refer to FIG. 2) by the method of the present invention. In this case, the blanks were heated in an atmospheric air in an electric furnace and the heating temperature was changed variously. Further, by controlling the heat retention time for each heating temperature at the time of heating, the thickness of the oxided scale formed during heating was equalized to be about 20 μm.

[0042] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com