Shearing interferometer with dynamic pupil fill

a technology of interferometer and pupil fill, which is applied in the field of photolithographic systems, can solve the problems of shorter wavelength light becoming absorbed by glass lenses and light not reaching silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

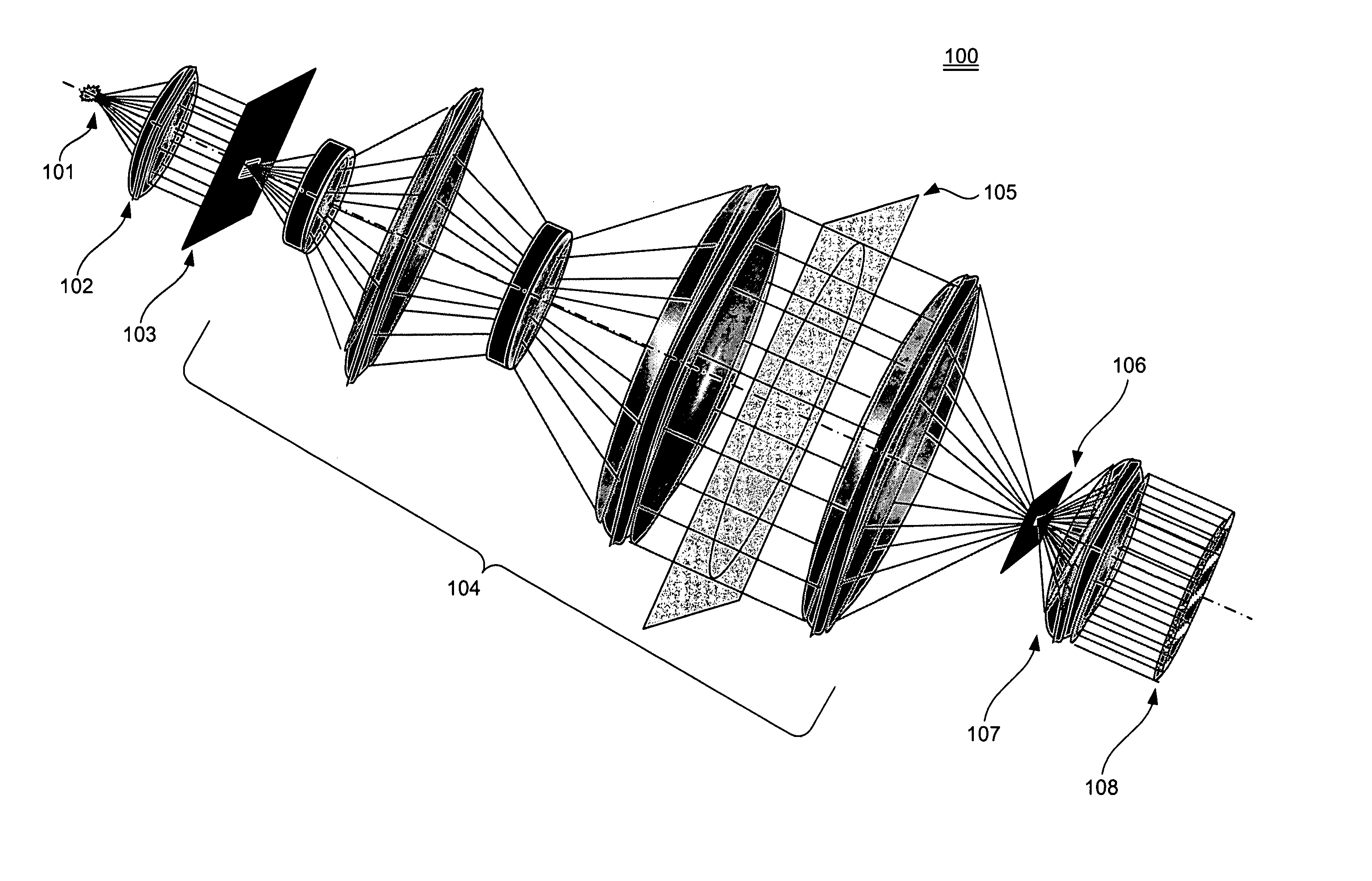

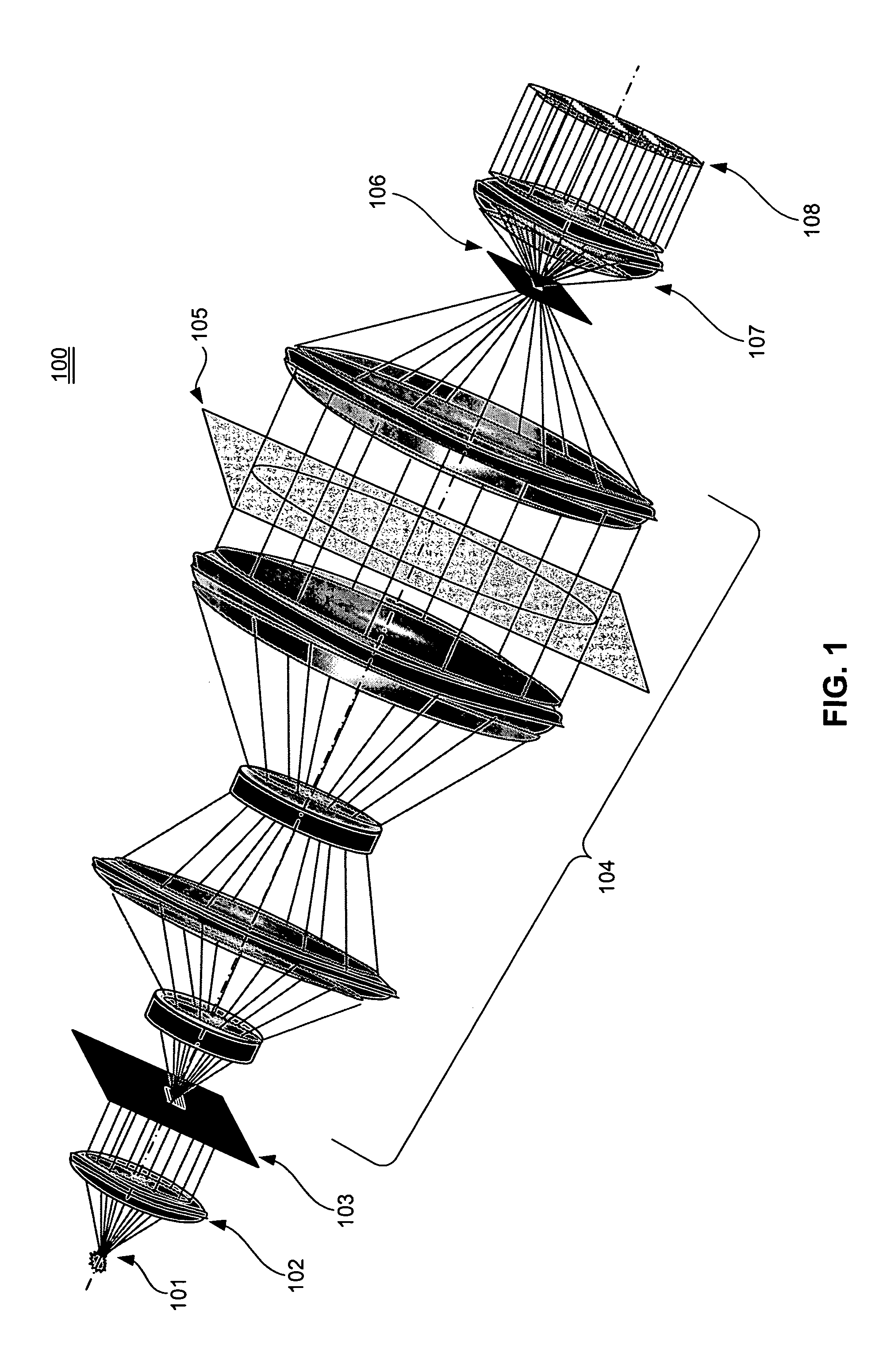

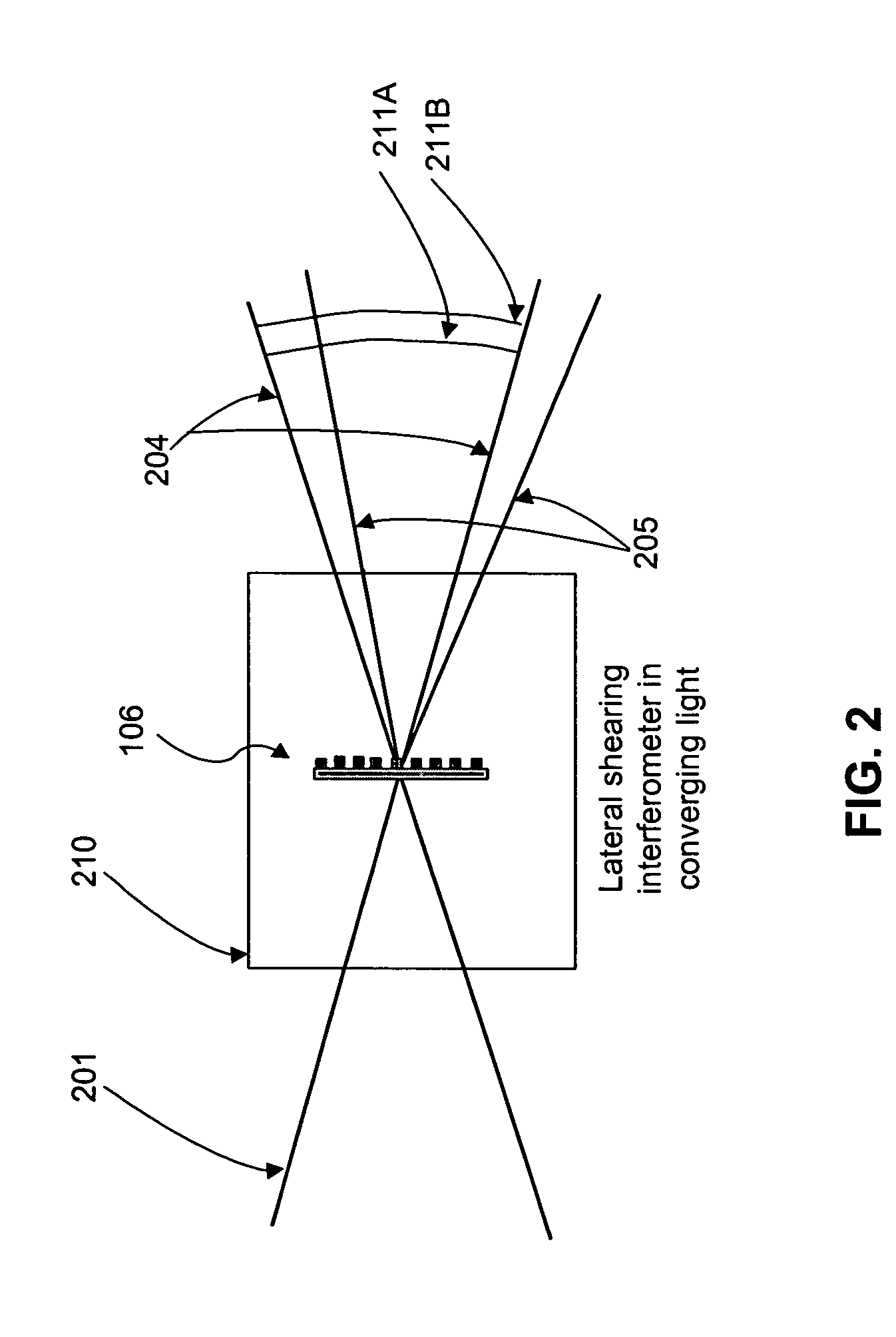

[0024] Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0025] It is convenient to characterize field-dependent aberrations of a projections optics (PO) by an aberration of a wavefront of a spherical wave emitted from a corresponding field point in the object plane. Various interferometry techniques can be used to measure aberration of this spherical wave. Shearing interferometry based on an extended incoherent source in the object plane superimposed with an object-plane grating matching the shearing grating is described in J. Braat and A. J. E. M. Janssen, Improved Ronchi test with Extended Source, J. Opt. Soc. Am. A, Vol. 16, No. 1, pp. 131-140, January 1999, incorporated by reference herein. Also, the paper by Naulleau et al., Static Microfield Printing at the ALS with the ETS-2 Set Optic, Proc. SPIE 4688, 64-71 (2002) (http: / / goldberg.lbl.gov / papers / Naulleau_SPIE—4688(2002).pdf), inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wedge angle | aaaaa | aaaaa |

| non-linear phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com