Process for cutting an optical fiber

a technology of optical fibers and cutting tools, applied in the field of cutting optical fibers, can solve the problems of time-consuming and, therefore, expensive, approach to mechanically cleaving and polishing optical fibers, and the angle of the end face of the optical fiber is generally limited to less than 15°, and achieves high degree of control, suitable results, and unprecedented accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

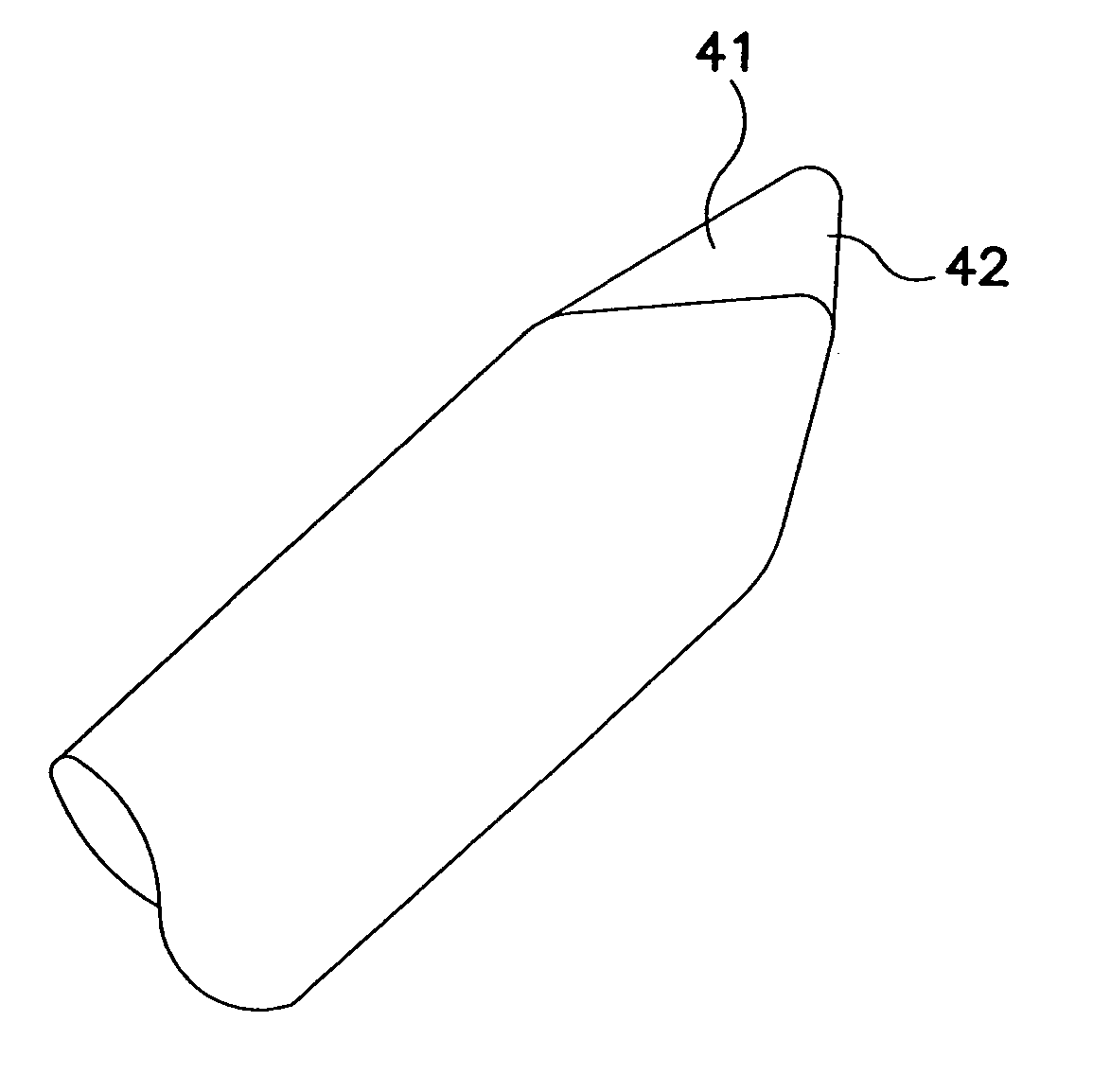

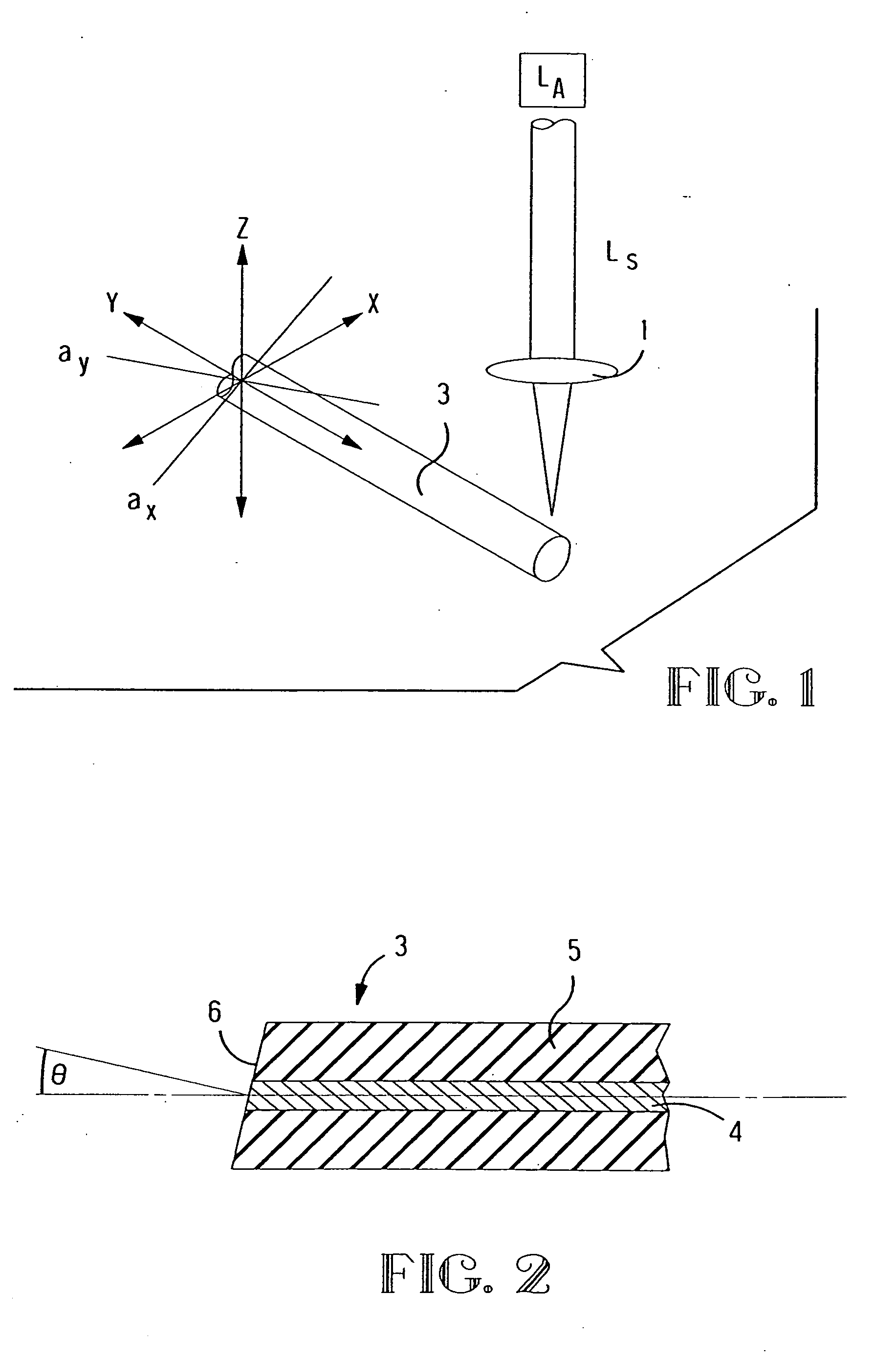

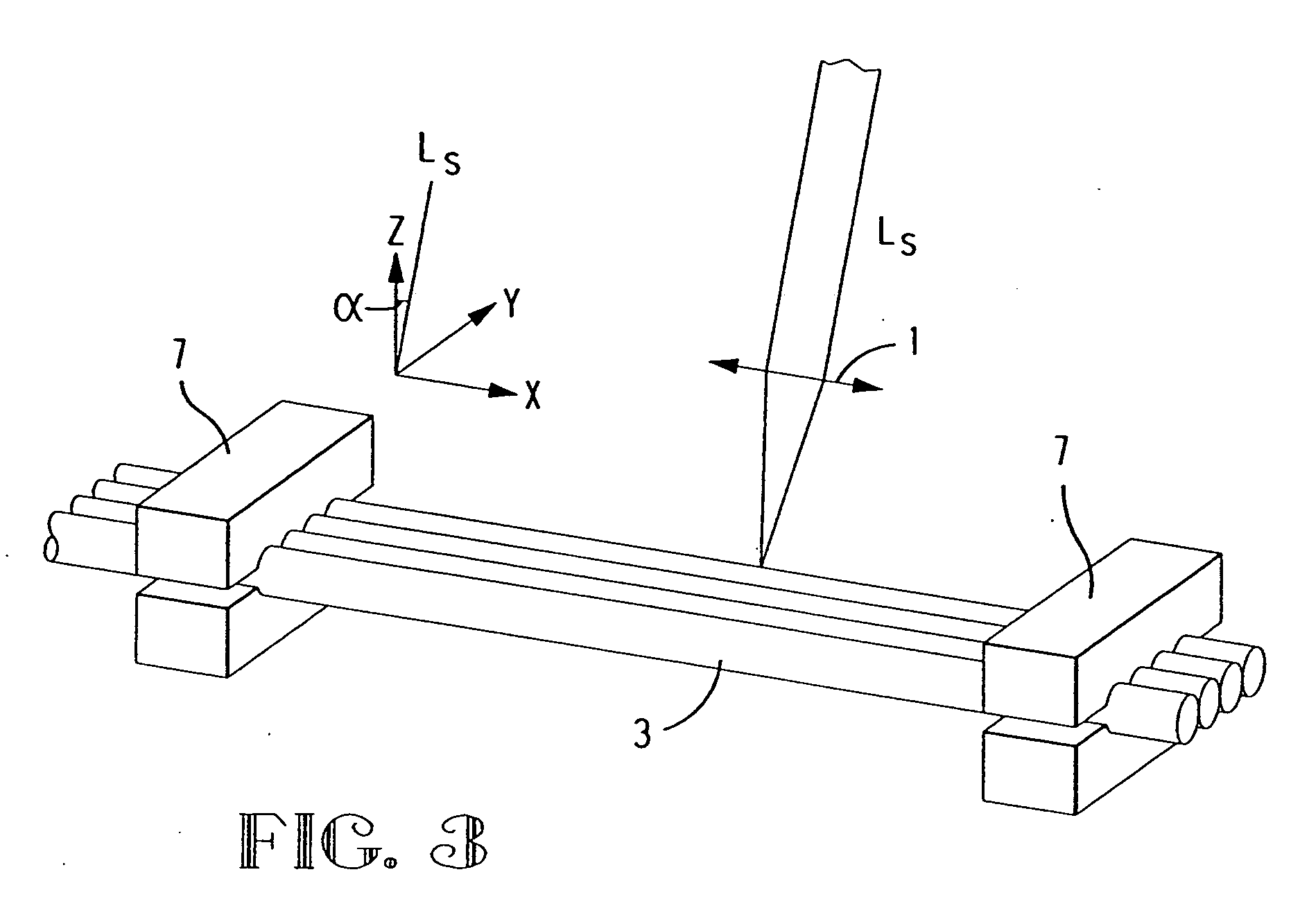

[0021] Referring to FIG. 1, a laser LA from which a laser beam LS issues is initially required for carrying out the process of cutting a fiber 3. The optical fiber 3 is a glass fiber, for example a monomode or multimode fiber. As shown in FIG. 2, the fiber 3 consists of a fiber core 4 and a fiber sheath 5 so that the light is guided substantially in the fiber core 4.

[0022] In general, any laser with a wavelength between 0.1 and 1.5 μm and 8.5 μm to 10μm can be used for producing the beam for cleaving the fibers. Suitable lasers include, for example, CO2 and excimer lasers, although a CO2 laser is preferred. CO2 lasers have proven particularly advantageous due to the high speed at which they can operate and their resultant cost effectiveness. The fiber material is removed by ablation by the CO2 laser during the cutting process, such that, rather than melting, the glass is sublimated.

[0023] Balancing the objective of delivery high energy to fiber to ablate the glass is the need to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| end face angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com