Golf ball

a golf ball and ball body technology, applied in the field of golf balls, can solve the problems of unintentional application of side spin by a less skilled golfer, unsuitable for use by the less skilled and/or high handicap golfer, and the soft thread wound ball is relatively difficult to manufacture, etc., to achieve the effect of improving compression and/or resilien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0122] Several spherical core components were produced utilizing the formulations set forth below (all amounts are parts by weight unless otherwise indicated):

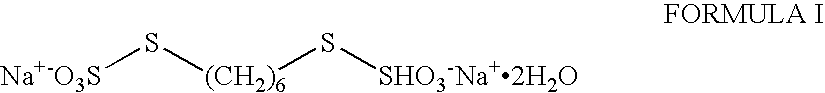

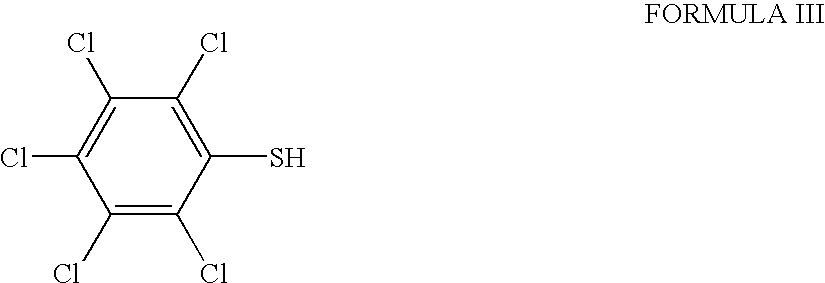

ControlIngredients (grams)ABCDCore Masterblend1165.65165.65165.65165.65Dansof Z2—0.5——RD 1302 Zn PCTP MB3—0.66—Duralink DHTS4———1Size1.5791.581.5781.576Weight38.7438.838.738.8I Comp0.09130.10300.10450.0899COR0.80590.80520.80500.8074Nes factor897.2908.2909.5897.3Nes Diff1112.30.11Masterblend:CB 1070NeoCis 6030Zn Oxide19.4Zn Stearate16ZDA29Trig 42 / 401.25165.652Dansof Z is a zinc salt of pentachlorothiophenol (Zn PCTP) availablefrom Dannier Chemical, Inc., Tustin, CA.3RD 1302 is Zn PCTP masterbatch from Rhein Chemie, Trenton, NJ.It is a 75% masterbatch of Zn PCTP in a high-cis polybutadiene rubber.4Duralink DHTS is 1,6-bis(thiosulfate), disodium salt, dihydrate availablefrom Flexsys America, Akron, Ohio.

[0123] The results indicated that the addition of the sodium hexamethylene-1,6-biothiosulfate, dihydrate (i.e., Duralink DHTS)...

example 2

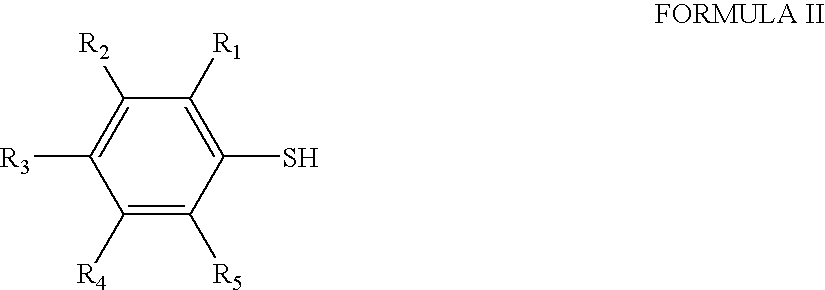

[0124] Additional core formulations were produced to determine whether any synergies existed through the combined use of the hexamethylene-1,6-bisthiosulfate, disodium, dihydrate along with a pentachlorothiophenol. These formulations are set forth below:

ControlIngredients (grams)ABCDCore Masterblend1165.65165.65165.65165.65RD 1302 Zn PCTP MB—0.660.660.66Duralink DHTS——12Size1.5011.5031.5031.502Weight34.1734.2134.3234.35I Comp0.08330.09300.09430.0964COR0.81460.81460.81770.8121Nes factor2897.9907.6912908.51Core Masterblend:CB 1070NeoCis 6030Zn Oxide19.4Zn Stearate16ZDA29Trig 42 / 401.25165.652Nes factor is determined by taking the sum of the Instrom compressionand resilience (C.O.R.) measurements and multiplying this value by 1000.It represents an optimal combination of softer but more resilient cores.

[0125] The data indicated that the addition of the hexamethylene-1,6-bisthiosulfate, disodium salt, dihydrate (Duralink DHTS), along with the zinc salt of pentachlorothiophenol (Zn-PCTP)...

example 3

[0128] Several different types of polybutadienes (CB 10, Necodene 60, and Neo Cis 60) and zinc diacrylates (ZDA), as well as varying amounts of zinc stearate, etc., were added to various formulations and compared to the use of the hexamethylene thiosulfate (DHTS) in combination with the zinc salt of pentachlorothiophenol (Zn-PCTP). These formulations are presented below:

ABCDPartsBWPartsBWPartsBWPartsBWCB 1070420704200000Neodene 600000100.00600100600Neo Cis 6030180301800000Zinc Oxide18.90113.417.510517.510516.599Zinc Stearate169616961696318TF ZDA30180000000ZDA100342043420435210Zn PCTP MB0.674.020.674.050.674.050.674.05Duralink DHTS00001616Trig 42 / 401.257.51.257.51.257.51.257.5ColorOrangePurpleGoldTanSize Pole1.5051.5071.5041.503Size EQ1.5051.5071.5051.503Weight34.1634.0534.0334.07Instron Comp0.10170.10120.10040.0993COR0.81000.81070.81290.8170Nes factor912912913916

1ZDA is SR 416, a modified ZDA, available from Sartomer.

[0129] The results indicated that the addition of the hexamethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com