Gas shut-off valve assembly

a technology of shut-off valve and assembly, which is applied in the direction of functional valve types, vessel construction details, gas/liquid distribution and storage, etc., can solve the problems of releasing hydrogen, and achieve the effect of easy determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

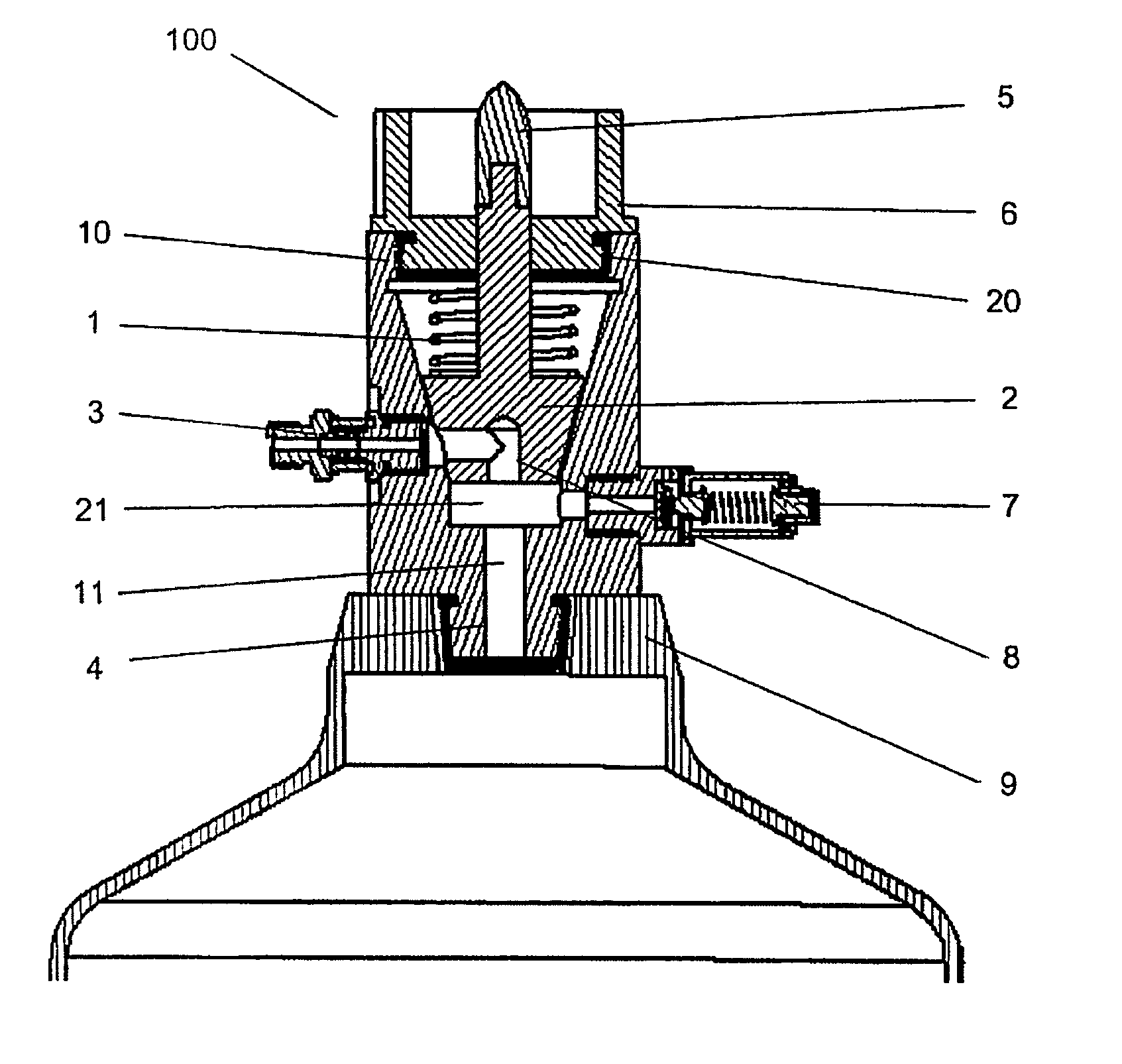

[0042] According to the invention and referring to FIGS. 3 to 6, a valve assembly 100 is provided that comprises four major components, namely: a rotatable gas shut-off valve 2, a quick-connect / detach outlet connector 3, a safety pressure relief device 7, and a bottle / canister inlet connector 4.

[0043] Directional terms such as “top”, “bottom”, and “side” used in reference to the assembly 100 are based on the inlet connector 4 being hereby defined as being at the “bottom” of the assembly 100. However, it is to be understood that such directional terms are used merely for convenient reference to assist in the description of the assembly 100, and are not to be construed as limiting the orientation of the assembly 100 in use or in connection to any other structure.

[0044] The shut-off valve 2 has a frusta-conical shape and is seated with its narrow end facing the bottom of a matching frusta-conical cavity and towards the inlet connector 4, i.e. upstream of the gas flow. Alternatively, t...

second embodiment

[0059] the assembly 102 is particularly usefully as it enables a gas-tight seal even if the spring 1 fails, as gas pressure from the bottle 9 will bias the valve 2 against the cavity surface.

[0060] Referring now to FIGS. 8(a) to (c) and according to a third embodiment of the invention, a valve assembly 104 is provided which is similar to the first embodiment except that the valve 30 a generally spherical shape, and the cavity extends laterally across the body 10 and has a generally hemispherical end that matches the shape of the valve 30. Also, the outlet connector 3 extends outwardly from the top of the body 10, and the knob 5 extends outwardly from the side of the valve 30 and through the knob guard 6, which is on or mounted to the side of the body 10 and serves to close the cavity. A compression spring 31 is located between the knob guard 6 and the valve 30 to bias the valve 30 against the cavity and establish a gas-tight seal therebetween.

[0061] A pair of blind openings 22 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com