Semiconductor integrated circuit device

a technology of integrated circuits and semiconductors, applied in semiconductor devices, digital storage, instruments, etc., can solve the problems of destroying the symmetry of memory cells, unable or at least very difficult to microfabricate ultrafine layout patterns, and increasing the requirements for micro-patterning architectures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

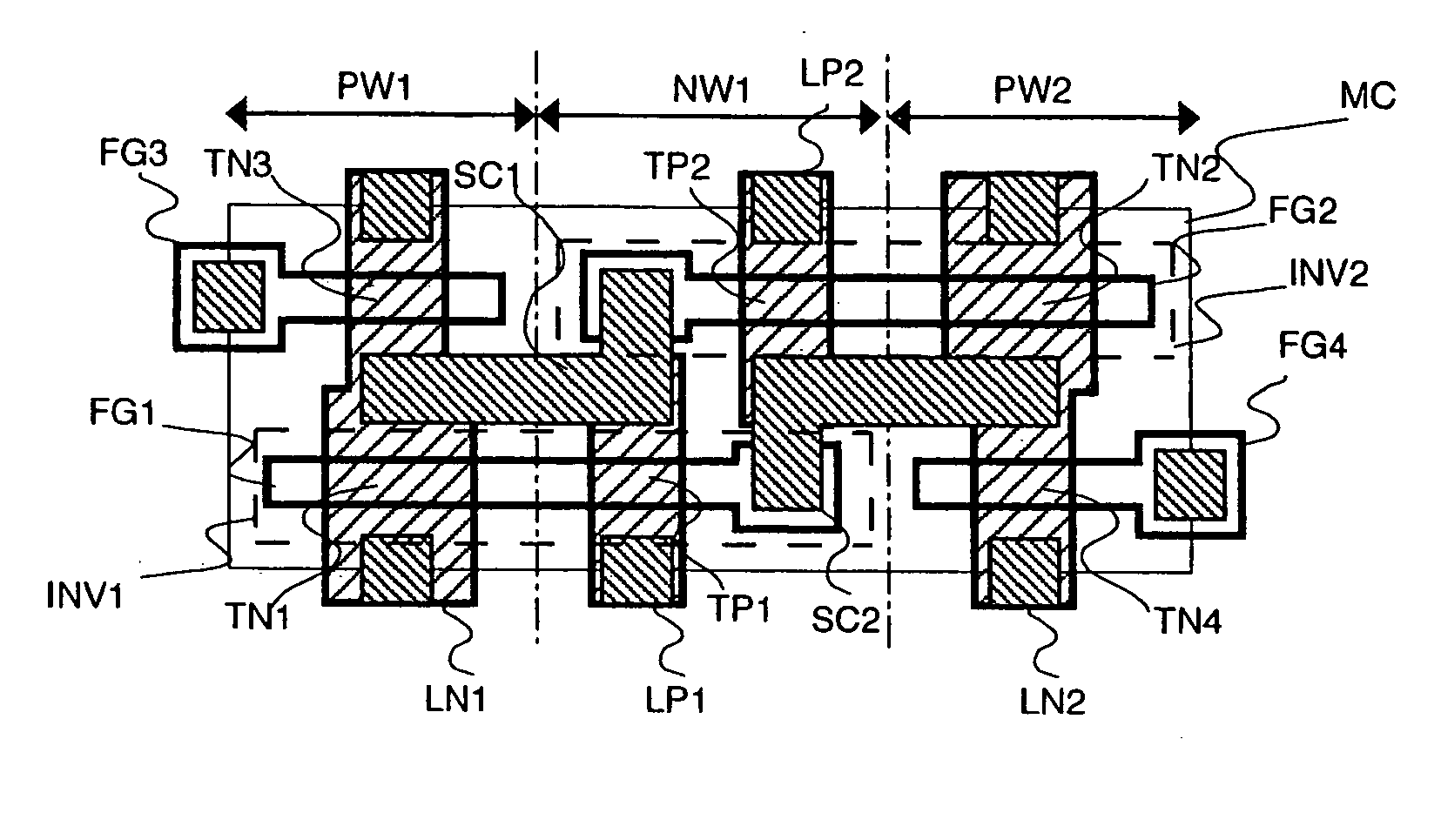

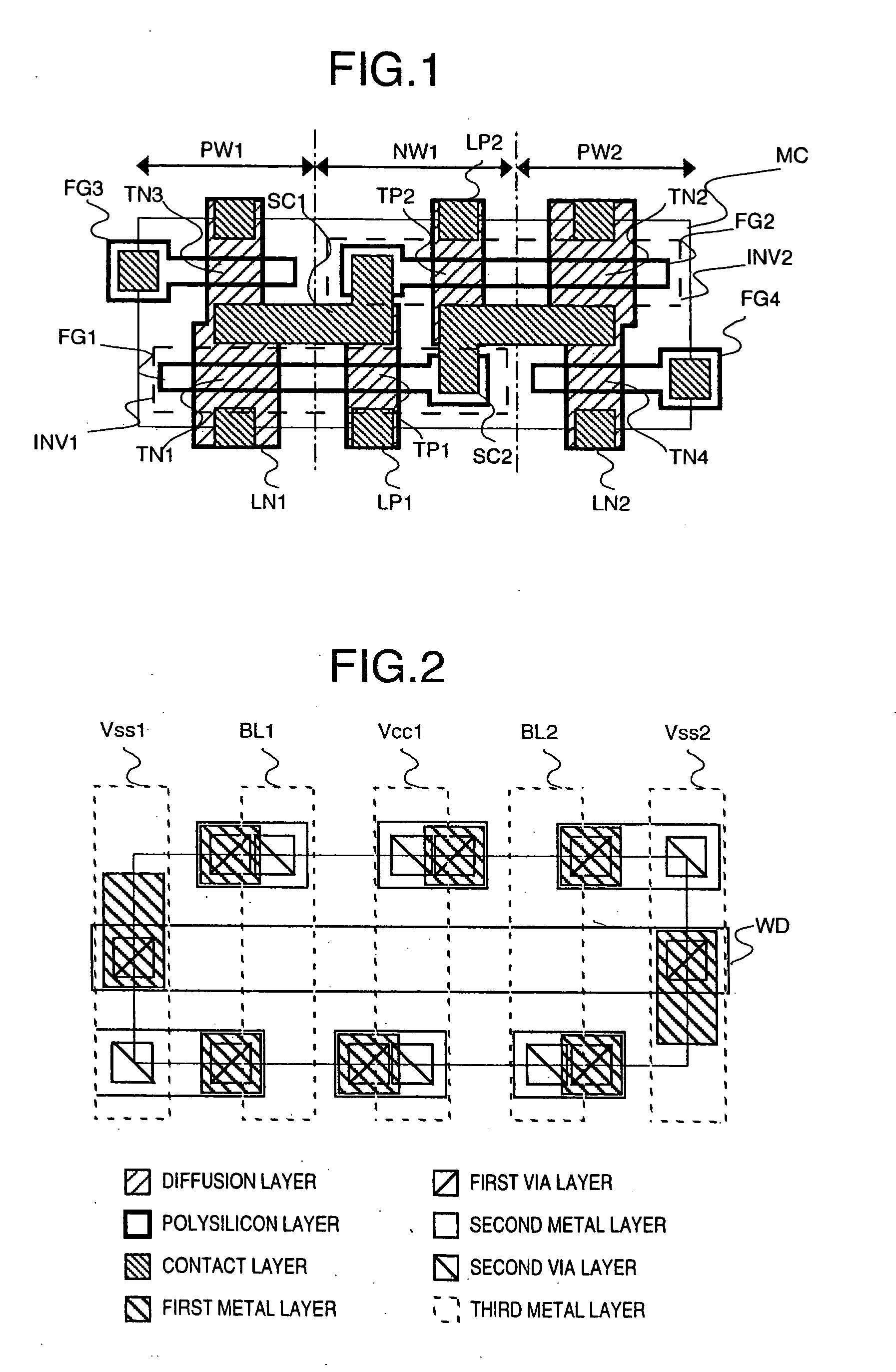

[0039] Referring to FIGS. 1 and 2, SRAM cell layout MC embodying the invention. FIG. 1 illustrates-well regions and diffusion layers plus a polycrystalline silicon interconnect lead layer, as well as contacts, all of which are formed in or over a semiconductor substrate FIG. 2 depicts a first layer serving as a metal lead layer, via holes 1, a second layer serving as a metal lead layer, via holes 2, and a third layer serving as a metal lead layer. Symbols used in FIGS. 1 and 2 are indicated at the lower part of FIG. 2.

[0040] An N-channel type MOS transistor TN1 formed in a P-type semiconductive well region PW1 and a P-channel type MOS transistor-TP1 formed in an N-type well region NW1 constitute an inverter INV1. In addition, an N-channel MOS transistor TN2 formed in P-type well region PW2 and a P-channel MOS transistor TP2 formed in N-type well region NW1 constitute an inverter INV2.

[0041] An output node of the inverter INVL is electrically connected by a contact SC1 to an input ...

embodiment 2

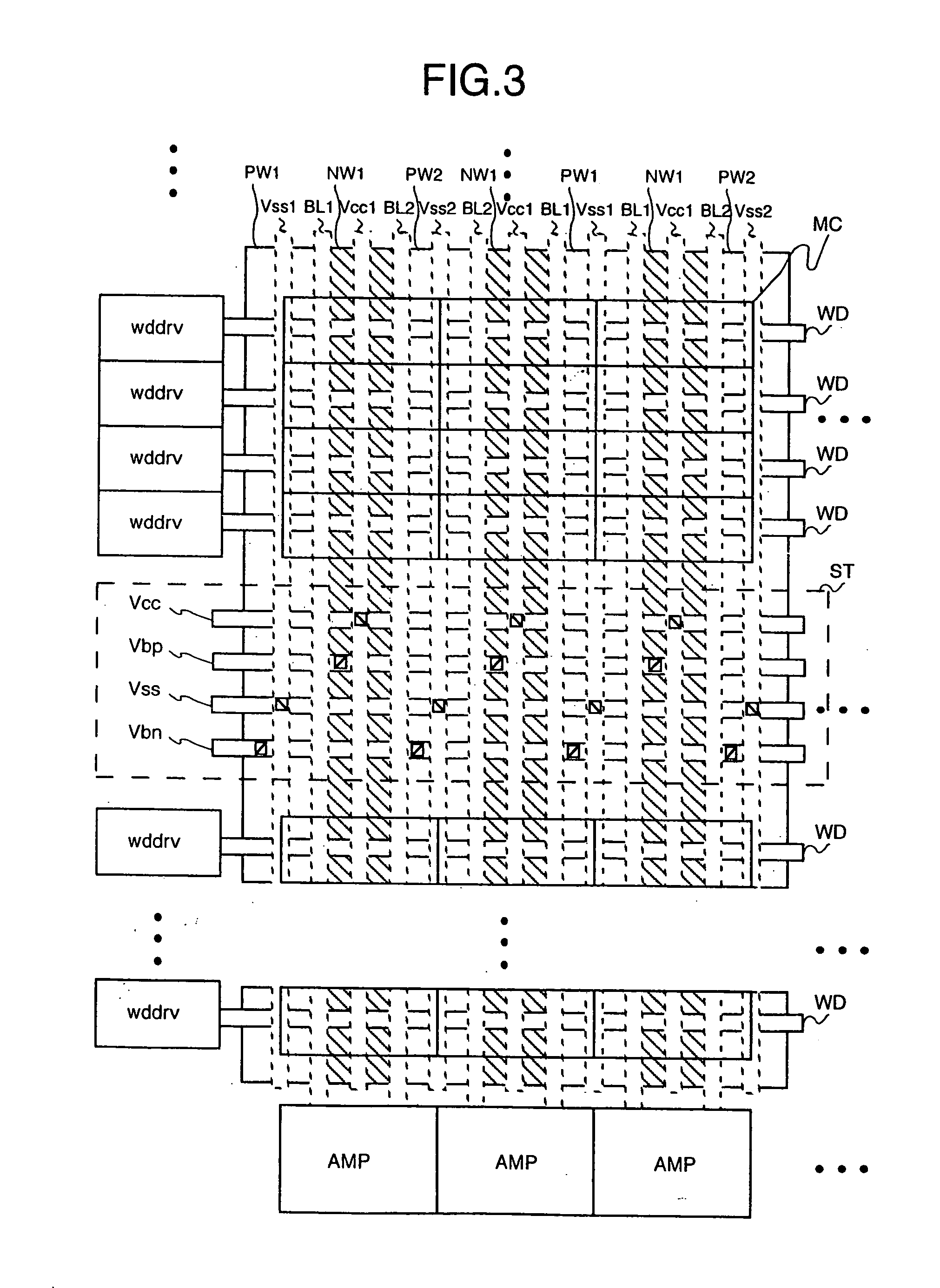

[0049] Turning to FIG. 3, an exemplary case is shown where the memory cells MC of Embodiment 1 are laid out into the form of an array. Symbols used herein are the same as those indicated at the lower part of FIG. 2.

[0050] The memory cells MC are organized into an array of 256 rows and 128 columns, by way of example. In view of the fact that these memory cells in Embodiment 1 are shorter in length in the longitudinal direction of the bit lines, the total length of the 256 rows of memory cells along the bit lines is shorter than that of prior art devices, thus increasing resultant operation speeds. Neighboring memory cells MC are disposed in linear symmetry with respect to a “y” axis whereas upper and lower adjacent memory cells MC are in linear symmetry with an “x” axis. In addition, specified regions ST for use in supplying more than one power supply voltage to the substrate are formed at the intermediate part of the array in such a manner that the regions ST extend parallel to wor...

embodiment 3

[0055]FIGS. 4 and 5 show a SRAM cell layout MC2 in accordance with Embodiment 3. Symbols as used in FIGS. 4-5 are the same as those in FIG. 2. Memory cell MC2 of Embodiment 3 is similar to the memory cell MC of Embodiment 1, with the exception that, as compared to Embodiment 1, in which the diffusion layer (LN1, LN2) is formed into a “T”-like planar shape, which resembles a Japanese battledore plate called “hagoita,” the diffusion layer (LN3, LN4) of Embodiment 4 is of a rectangular shape, and the contacts (SC1, SC2) are replaced with contacts (SC3, SC4) in the first layer serving as metal lead layers (M11, M12).

[0056] To attain stability, memory cells are typically designed so that the gate width of the N-channel MOS transistors (TN1, TN2) is one and a half times greater than that of the N-channel MOS transistors (TN3, TN4) However, in this case, the shape of the diffusion layers resembles a T-like planar shape, as shown in Embodiment 1, which in turn requires extra techniques, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com