Acoustic fluid machine

a fluid machine and acoustic technology, applied in the direction of machines/engines, instruments, sound producing devices, etc., can solve the problems of high cost, complex structure, and inability to obtain the desired discharge pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

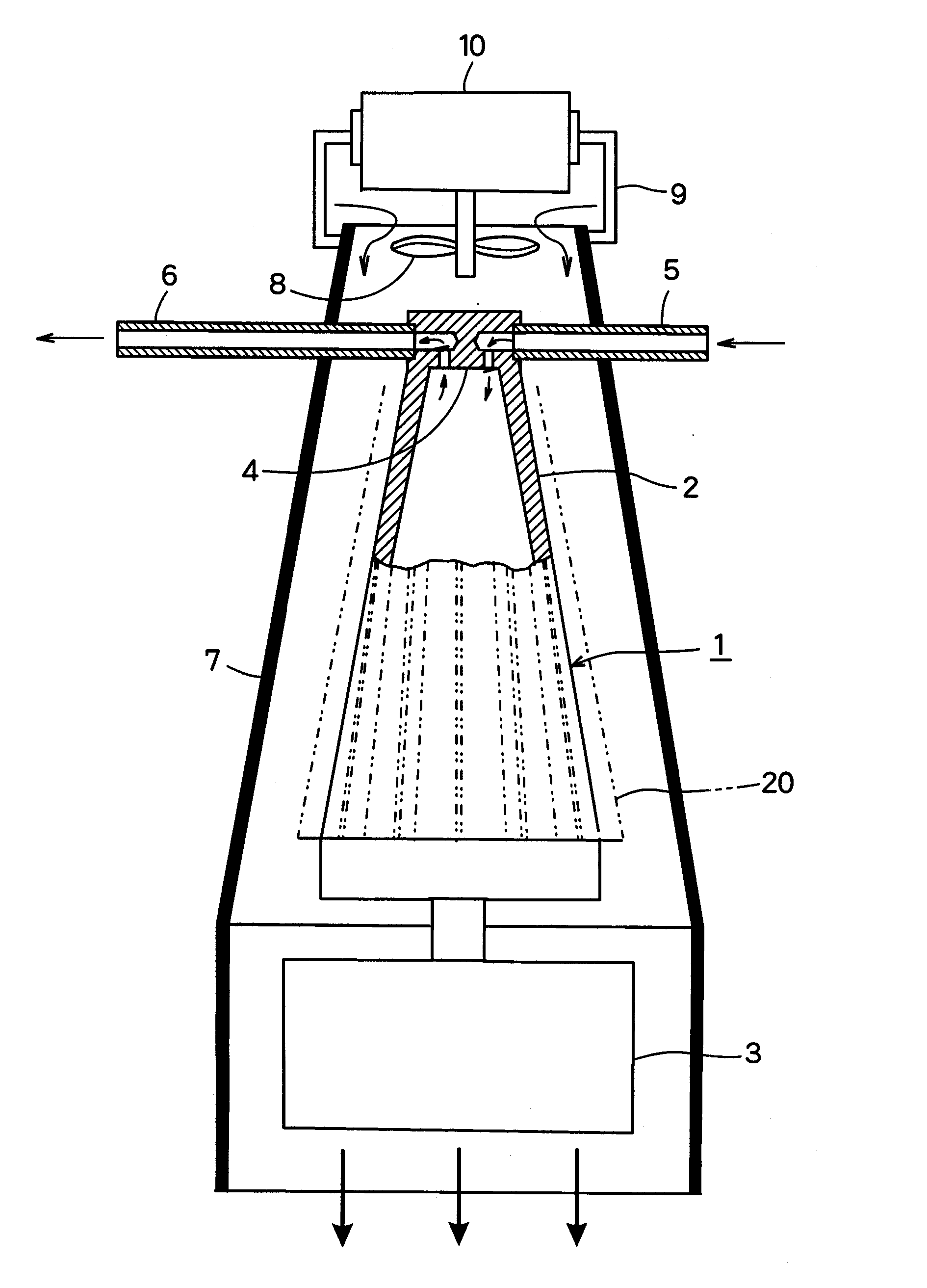

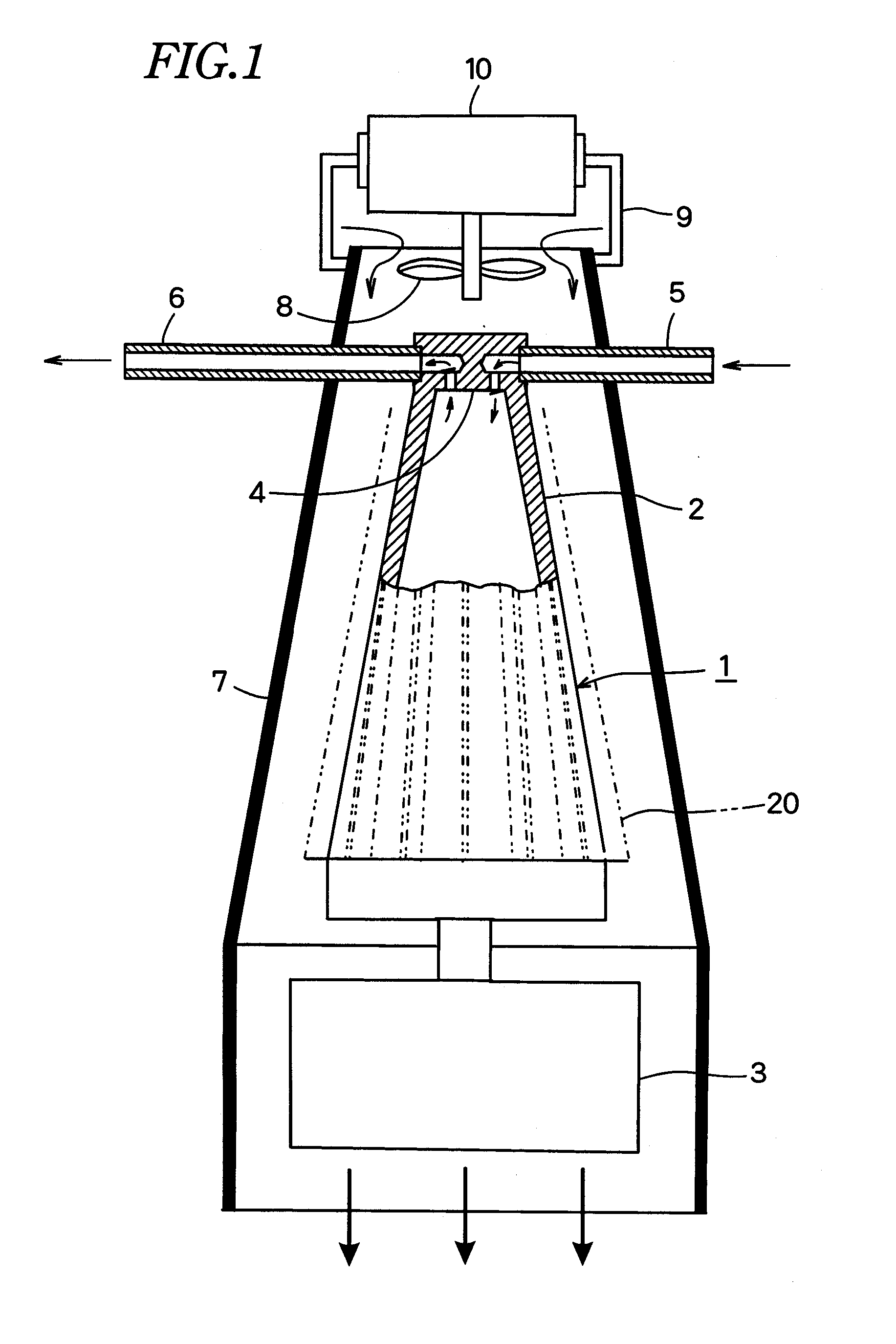

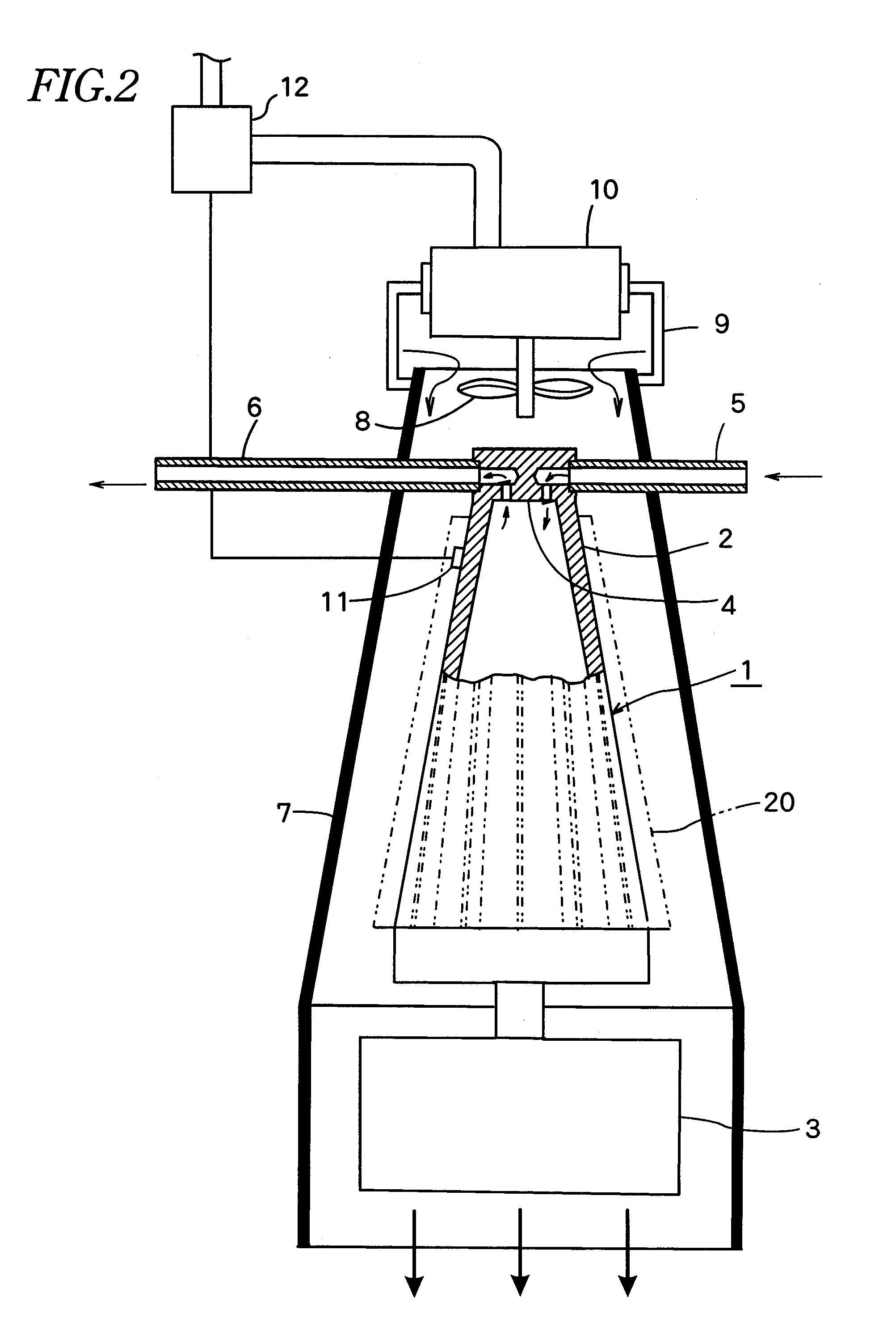

[0016] Numeral 1 denotes an acoustic fluid machine in which an acoustic resonator 2 has an actuator 3 in a larger-diameter base. A piston (not shown) is reciprocated axially at high speed at very small amplitude. Owing to pressure fluctuation in the acoustic resonator 2 involved by reciprocal motion of the piston, air and other fluid are sucked into the acoustic resonator 2 through a sucking pipe 5 and discharged from a discharge pipe 6.

[0017] The acoustic fluid machine 1 is contained with a space in a gas guide 7 that opens at the top end and the base end. A fan 8 is provided inside the top end of the gas guide 7.

[0018]FIG. 1 shows that the fan 8 is driven by an electric motor 10 mounted to the outer surface of the top end of the gas guide 7 by a bracket 9.

[0019]FIG. 2 shows that a control unit 12 allows electricity supplied into the electric motor 10 in FIG. 1 to vary depending on detected temperature of a temperature sensor 11 in the acoustic resonator 2. Thus, the quantity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com