Method for removing polyphenylene sulfide byproduct dry salt organic substance adopting self-propagating heat-storing incinerating device

An incineration device and polyphenylene sulfide technology, applied in the direction of combustion methods, raw material granulation methods, chemical instruments and methods, etc., can solve the problems of lithium salt purification affecting the quality of lithium salts, etc., to achieve reduced losses and uniform temperature distribution , the effect of small gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

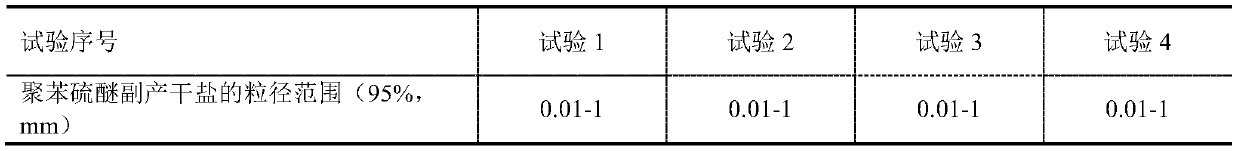

[0023] A self-propagating thermal storage incineration device is used to remove the dry salt organic matter of the by-product of polyphenylene sulfide. The dry salt of the by-product of polyphenylene sulfide comes from a polyphenylene sulfide production enterprise. Before treatment, it mainly contains NMP, PPS short chain (oligomeric substances) and organic substances such as thiophenol.

[0024] First, the by-product dry salt is homogenized until the particle size is less than 3mm, and then pelletized with a binder (10% syrup solution). N, the number of drops ≥ 15.

[0025] Pellets and agricultural waste (straw) are formed into a mixed material, and the agricultural waste accounts for 5%. The above mixed material is pyrolyzed, wherein, the thickness of the pyrolyzed material layer is 350mm, and the pyrolysis temperature is 653°C. After a certain period of time, the material layer is cooled to obtain the finished salt, and the specific parameters of the finished salt after py...

Embodiment 2

[0030] The polyphenylene sulfide used in the above-mentioned test 1 is enlarged, and the method is as follows: figure 1 For the shown pyrolysis device, the processing capacity is increased to 1 ton, and the method is as shown in Example 1, pyrolyzing for 1.5 hours. After pyrolysis, the finished salt in different positions of the material layer is taken for inspection. The finished salt is brown in appearance and particle size Uniform, no melting and agglomeration, the particle size range of the finished salt is 3-10mm, the TOC is 216ppm, the lithium content is 2.29%, and the lithium loss rate is 0.4%.

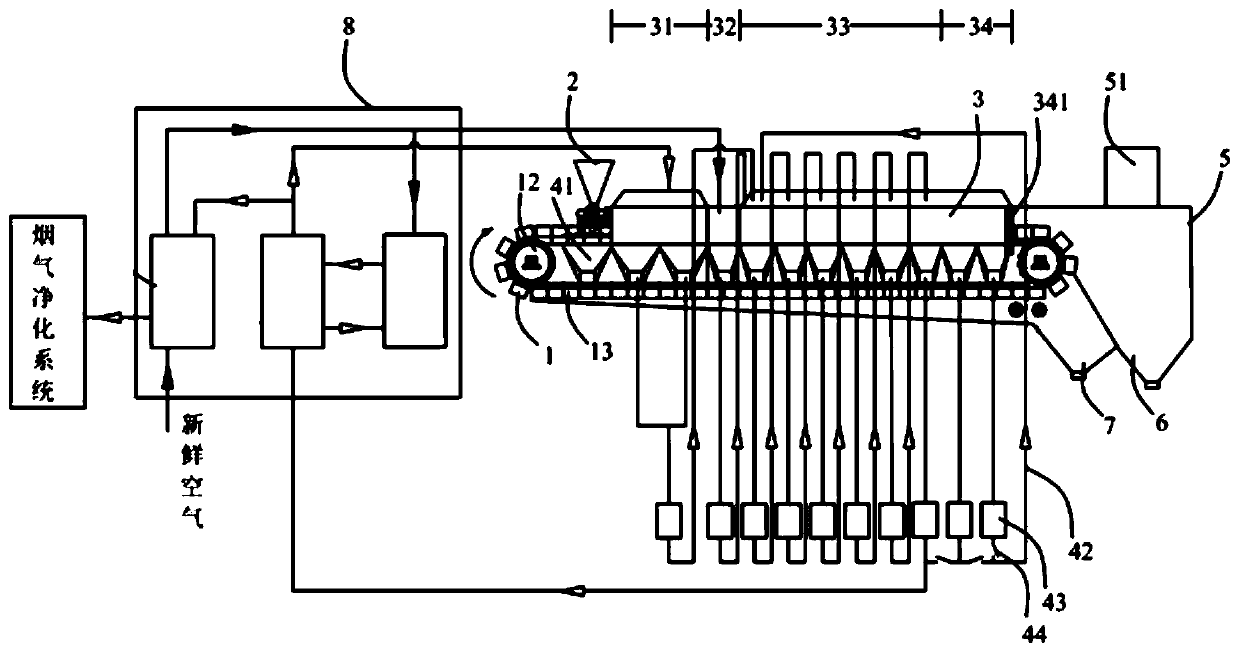

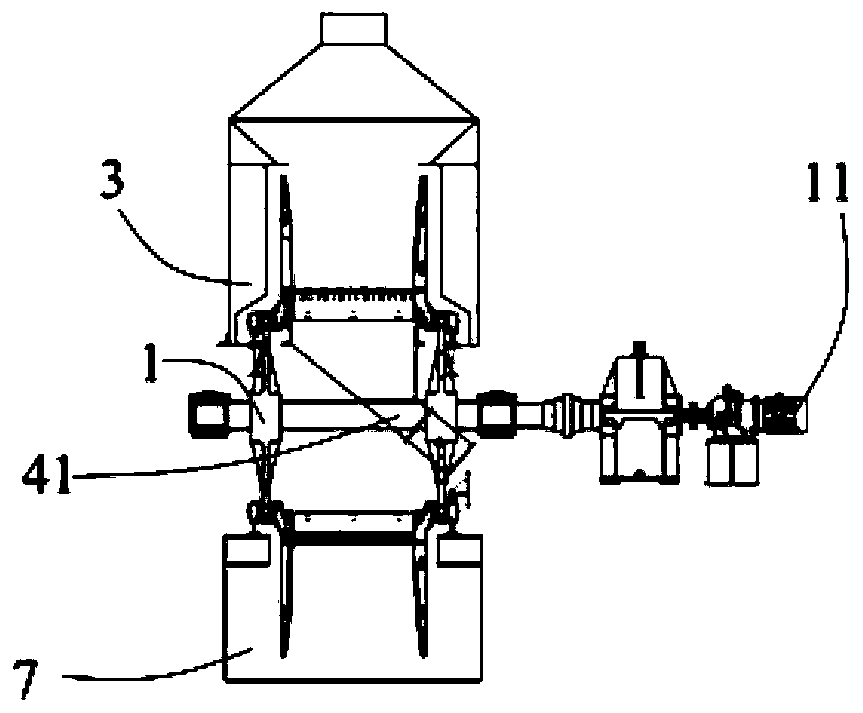

[0031] see figure 1 , the self-propagating pyrolysis negative pressure heat storage device includes a chain-belt conveyor 1, and the chain-belt conveyor 1 is composed of a drive mechanism 11 (not marked), a sprocket 12 and a chain belt 13 matched with the sprocket 12; Above the head of the chain-belt conveyor 1 along the direction of travel of the chain belt 13, a distributor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com