Golf ball with polysulfide rubber layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

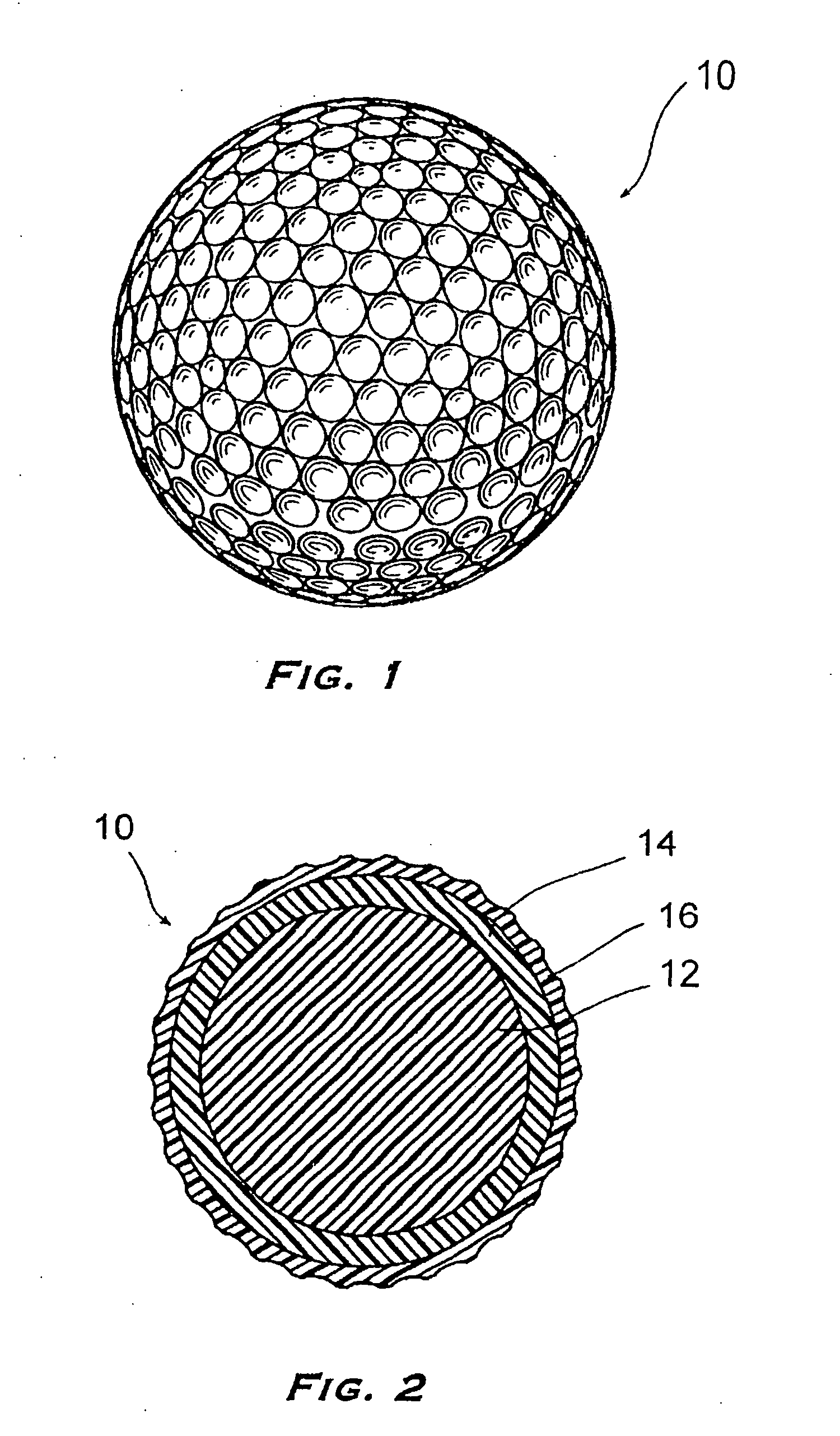

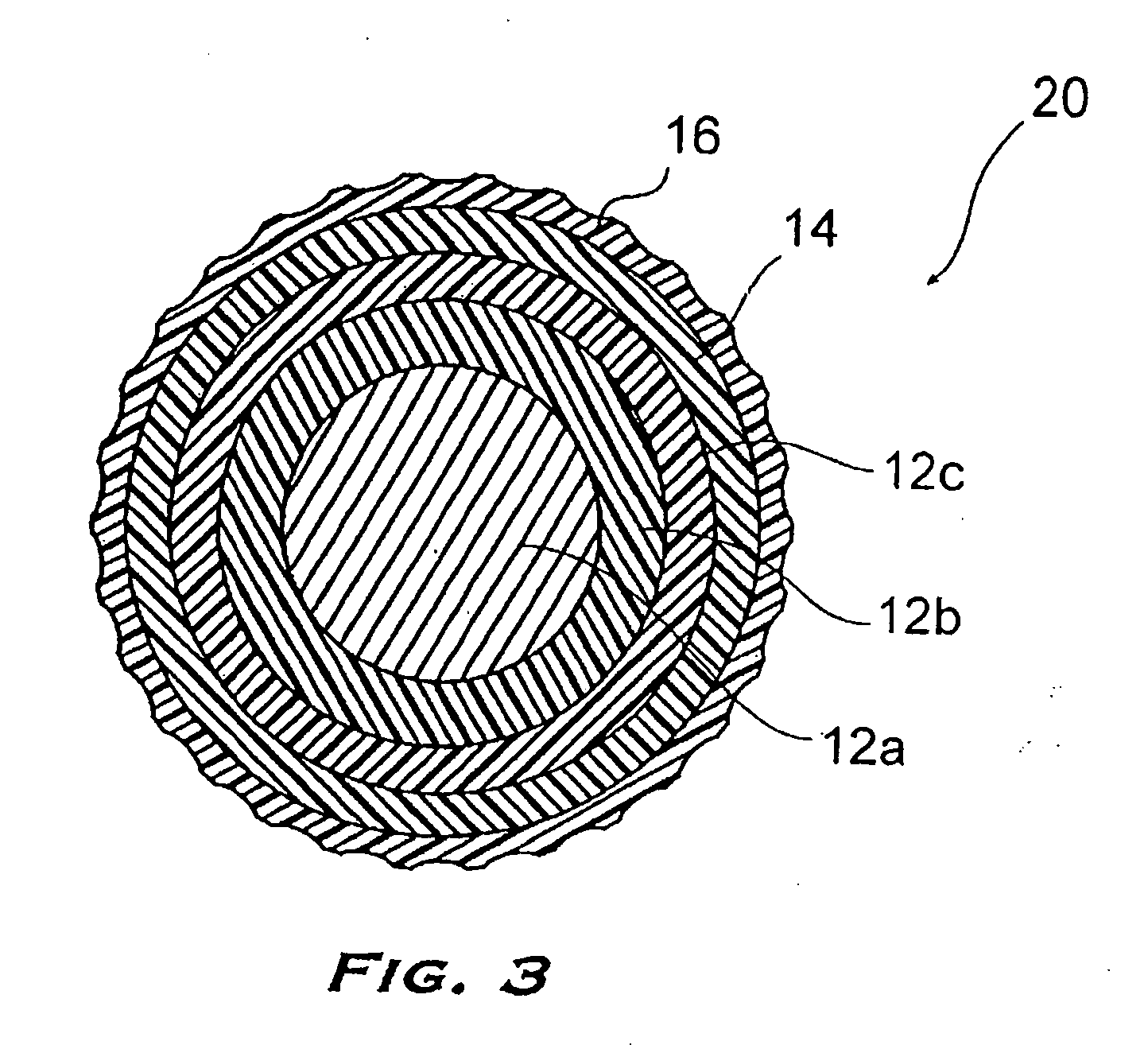

[0019] As shown generally in FIGS. 1 and 2, where like numbers designate like parts, reference number 10 broadly designates a golf ball in accordance to the present invention. Golf ball 10 preferably has a solid core 12, an intermediate layer 14 and a cover 16. Solid core 12 may comprise a single spherical element, or it may comprise a core spherical element with one or more intermediate layers surrounding the spherical element. Solid core 12 can be made from any suitable core materials including thermoset plastics, such as natural rubber, polybutadiene (PBD), polyisoprene, styrene-butadiene or styrene-propylene-diene rubber, and thermoplastics such as ionomer resins, polyamides, polyesters, or a thermoplastic elastomer. Suitable thermoplastic elastomers include Pebax®, which is believed to comprise polyether amide copolymers, Hytrel®, which is believed to comprise polyether ester copolymers, thermoplastic urethane, and Kraton®, which is believed to comprise styrenic block copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com