Cleaning method and cleaning apparatus for performing the same

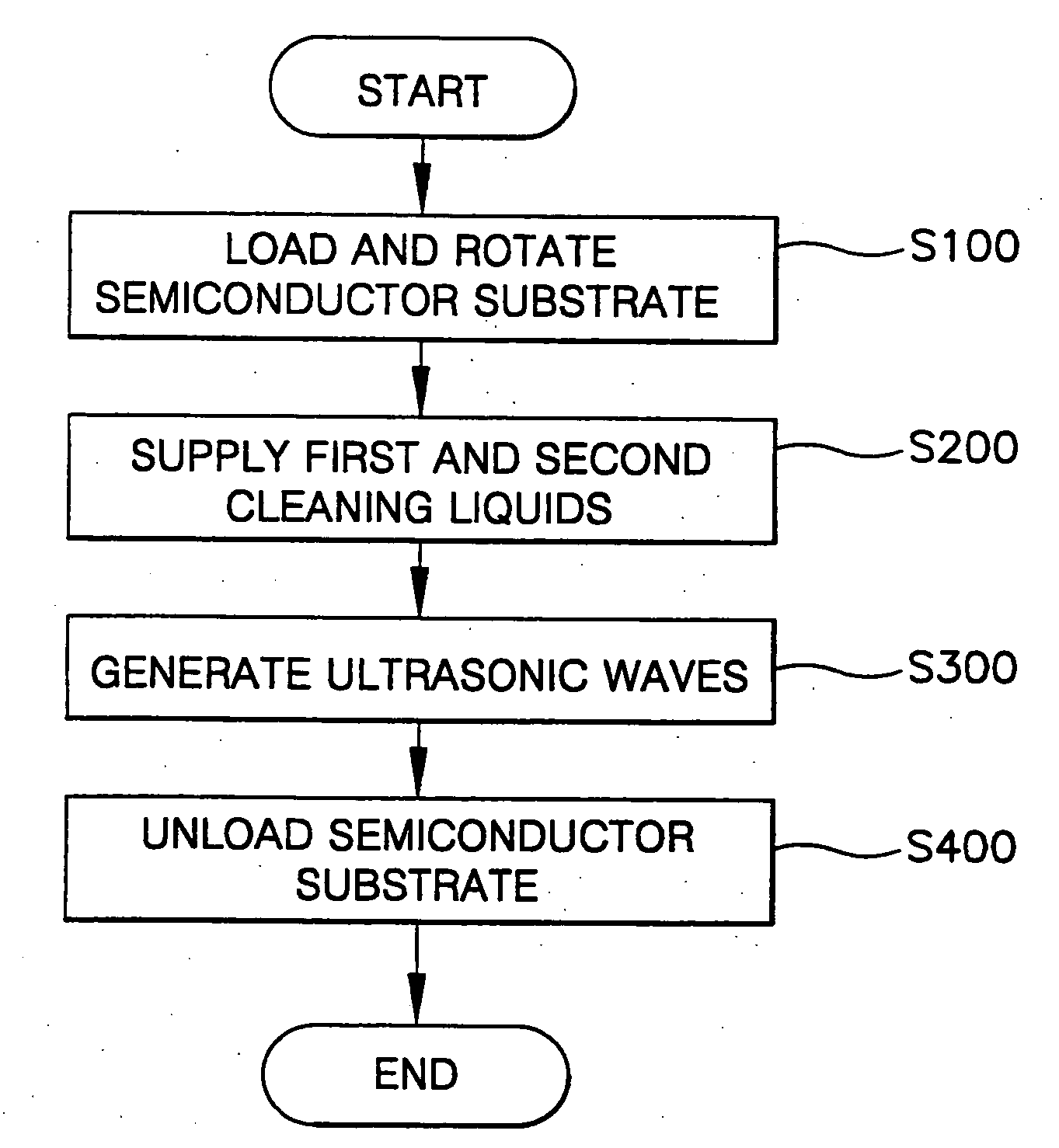

a cleaning method and cleaning method technology, applied in the direction of cleaning process and apparatus, cleaning using liquids, cleaning methods, etc., can solve the problems of lowering the yield and productivity of the semiconductor device, batch cleaning methods may not effectively clean the edge and side sections of the semiconductor substrate, and the cleaning method may not effectively remove the impurities sticking to the side and bottom sections of the semiconductor substrate. , to achieve the effect of improving the cleaning effect and improving the cleaning effect with respect to the edge and side sections of the semiconductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0064] Table 1 shows test results of cleaning efficiency with respect to the semiconductor substrate. The tests were carried out with applying the ultrasonic waves to SC1 solution and without applying the ultrasonic waves to general SC1 solution.

TABLE 1Power3060usedsecsecSC1 (without ultrasonic wave)031.0%35.0%SC1 (both surfaces of substrate) +5099.7%99.3%ultrasonic wave (upper surface of7581.4%92.5%substrate10084.8%93.1%12585.4%95.8%Deionized water (upper surface of5098.7%—Frontsubstrate) + SC1 (lower surface ofloadingsubstrate) + ultrasonic wave5099.7%—Bottom(upper surface of substrateloading

[0065] In the above test, the semiconductor substrate was intentionally contaminated with silicon nitride (SiN) gel, and the silicon nitride gel was removed by using SC1 solution having a temperature of about 65° C. The frequency of the ultrasonic wave was 830 kHz.

[0066] In the first test, the semiconductor substrate was loaded such that a surface formed with the silicon nitride gel was upw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| incident angle | aaaaa | aaaaa |

| incident angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com