Flexible land grid array connector

a flexible land and grid array technology, applied in the direction of dielectric characteristics, printed element electric connection formation, coupling device connection, etc., can solve the problems of reducing the pitch between contacts, broken interconnections, and unreliable cga solder connections, so as to achieve reliable electrical connections and enhance durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

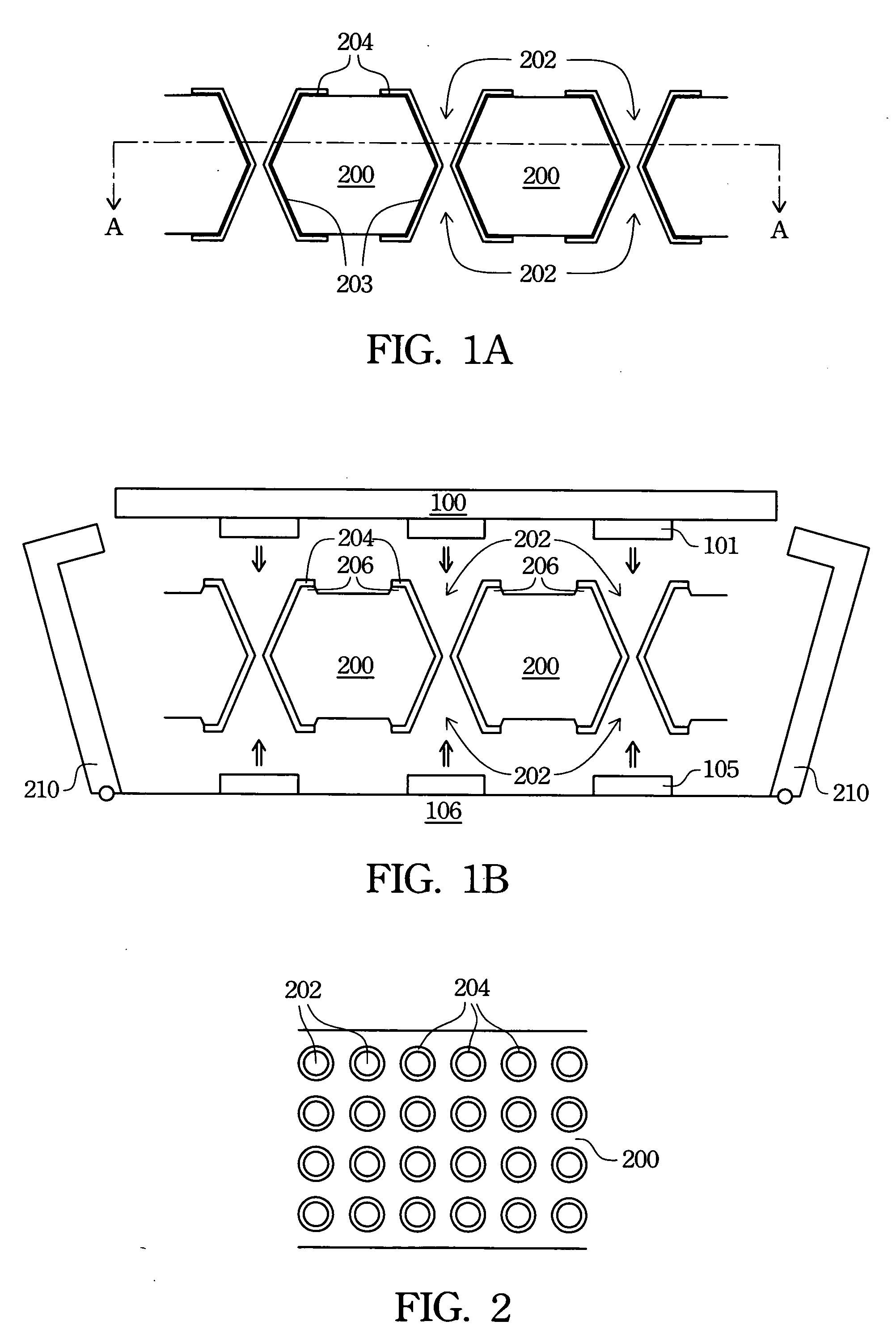

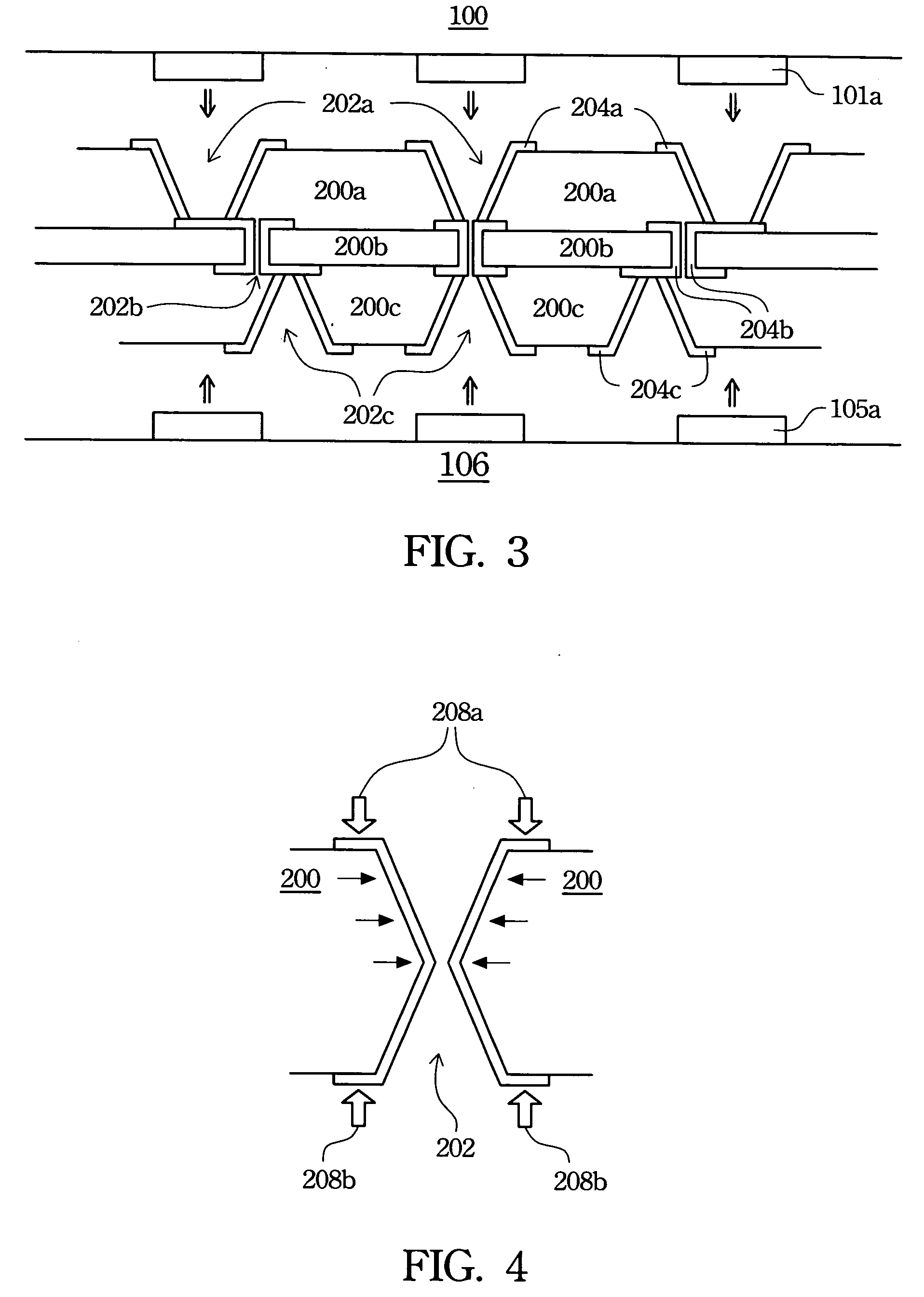

[0020] In order to overcome the shortcomings of the prior art, the present invention provides an LGA connector for solderless connection between an LGA package and a printed circuit board. The LGA connector is an elastomeric body having a plurality of through-holes. There is a metal layer on an inner wall and around each upper and lower opening of each through-hole so as to interconnect an LGA package and a printed circuit board.

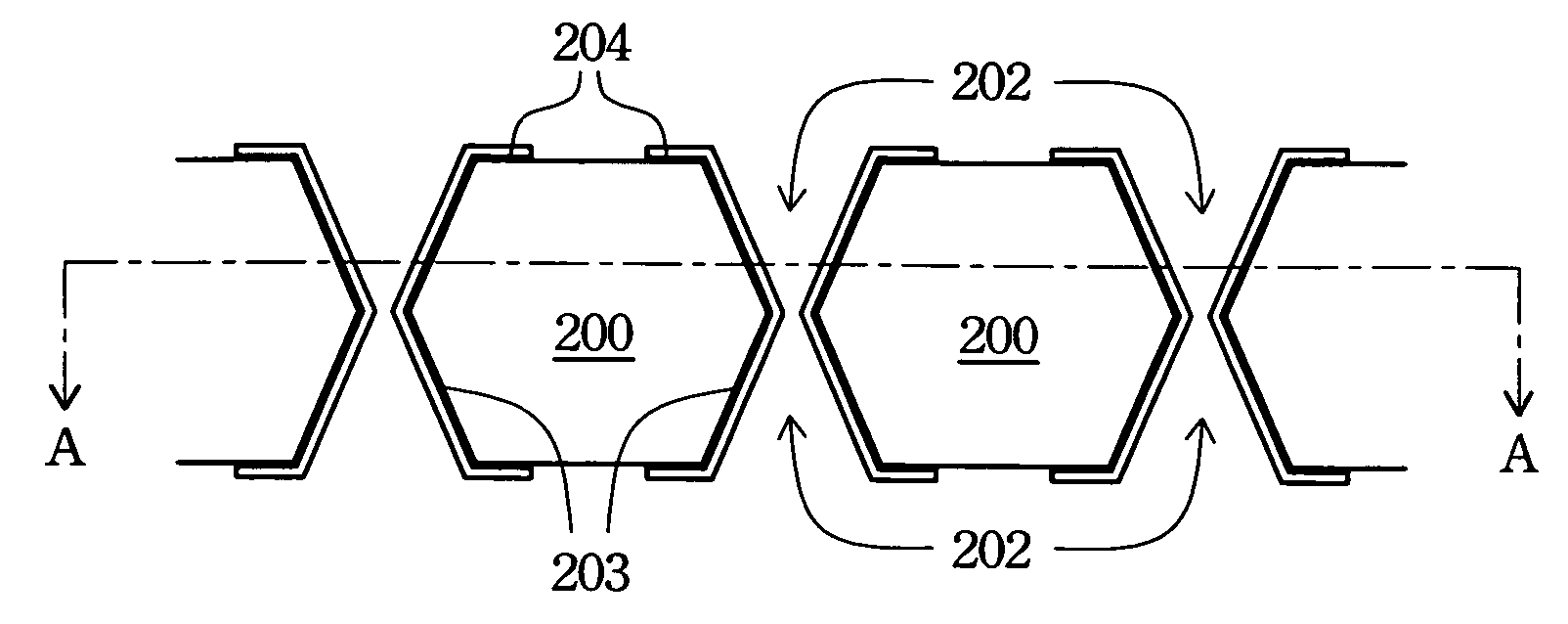

[0021]FIG. 1A illustrates a cross-sectional view of an LGA connector according to one preferred embodiment of this invention. The LGA connector includes an elastomeric body 200 made of rubber, which has a plurality of funnel-like through-holes 202 formed by etching. A meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com