Fluid lubricant

a fluid lubricant and fluid technology, applied in the field of fluid lubricant, can solve the problems of limiting the temperature range of operation, difficult to find additives, and degradation of tractive drive, and achieve the effects of low viscosity, high traction coefficient, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

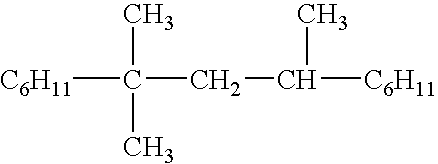

Image

Examples

example 4

[0034] Fluid lubricants were tested with varying amounts of AMS:PAO ratios by weight at ambient conditions. The fluid lubricants were tested to determine the actual coefficient of traction versus the calculated coefficient of traction. The AMS and PAO constituents were combined in a beaker and mixed with a magnetic stir rod until the fluid lubricant mixture was created. The fluid lubricants prepared with the varying ratios of 20:80, 30:70, and 40:60 were analyzed and the below data was collected.

Coefficient100%100%AMS:PAOAMS:PAOAMS:PAOof TractionAMSPAO20:8030:7040:60Calculated0.0350.0420.057Actual0.0950.0200.0520.0600.075

[0035] The data above illustrates the synergistic relationship discovered between the AMS and PAO components. The AMS and PAL when combined to produce the fluid base have a synergistic effect on the fluid lubricant mixture. The synergistic effect causes the fluid lubricant to possess a coefficient of traction that is higher than calculated. The coefficient of trac...

example 1

[0042] AMS and PAO 4 were blended together at a ratio of 20:80 by weight at ambient conditions to form the base fluid. Performance additives were then added to the base fluid and are as follows: [0043] VI improver, Crompton Corp, CP80 at 2.00 Wt % [0044] Friction Modifier, Exxon Mobil®, DIDA at 5.00 Wt % [0045] Antioxidant, Ciba® LO6 at 0.75 Wt % [0046] Antiwear agent, Ciba® TPPT at 1.25 Wt % [0047] Antifoam agent, Ultra additives Foamban 130B at 0.1 Wt %

[0048] The fluid lubricant prepared with the 20:80 ratio of AMS:PAO 4 was analyzed and the below data was collected.

Physical Properties

[0049]

PropertiesResultsViscosity at 100° C.7.4cStViscosity at 40° C.40.3cStViscosity at −40° C.13,500cStCoefficient of Traction0.052Four-ball wear Test0.45Evaporation Loss at 155° C. / 100 hours4.6Foam Test seq I10mlOxidation Stability Test,192 hrs at 170° C.Viscosity Change %2.8Total Acid number change0.23Copper Corrosion 100° C. / 24 hours1APour Point Temperature−56°C.

[0050] The data above illustrat...

example 2

[0058] AMS and PAO 4 were blended together at a ratio of 40:60 by weight at ambient conditions to from the base fluid. The performance additives as described in example 1 were then added to the base fluid.

[0059] The fluid lubricant prepared with the 40:60 ratio of AMS:PAO 4 was analyzed and the below data was collected.

Physical Properties

[0060]

PropertiesResultsViscosity at 100° C.7.3cStViscosity at 40° C.41.3cStViscosity at −40° C.19,500cStCoefficient of Traction0.075Four-ball wear Test0.46Evaporation Loss at 155° C. / 100 hours7.6Foam Test seq I15mlOxidation Stability Test,192 hrs at 170° C.Viscosity Change %4.8Total Acid number change0.43Copper Corrosion 100° C. / 24 hours1APour Point Temperature−54°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com