Magnetic assembly for a linear beam tube

a technology of linear beam tube and magnetic assembly, which is applied in the direction of discharge tube/lamp details, magnetic discharge control, transit tube circuit elements, etc., can solve the problems of different constraints in assembly or disassembly of the device, density modulation of electron beam,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

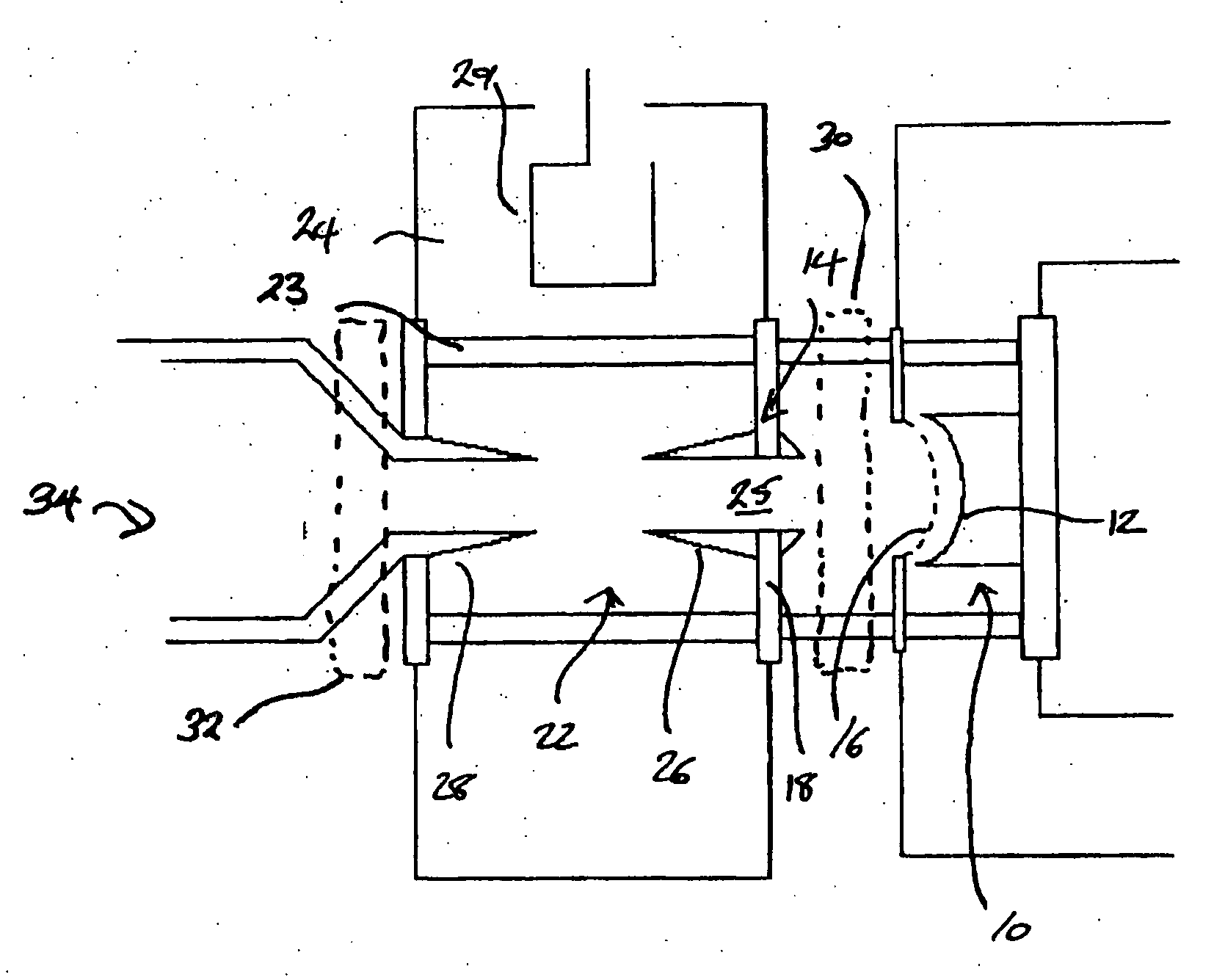

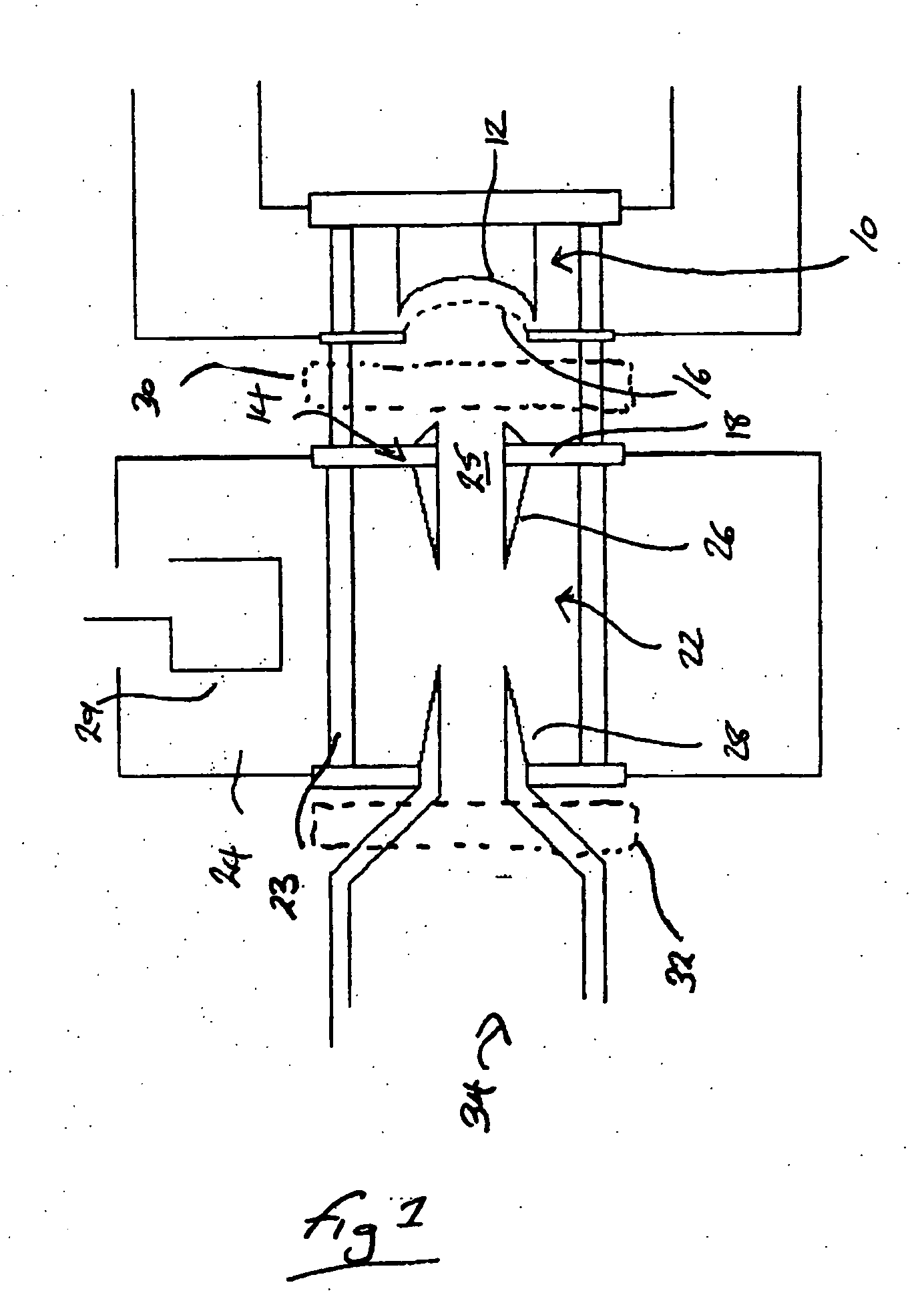

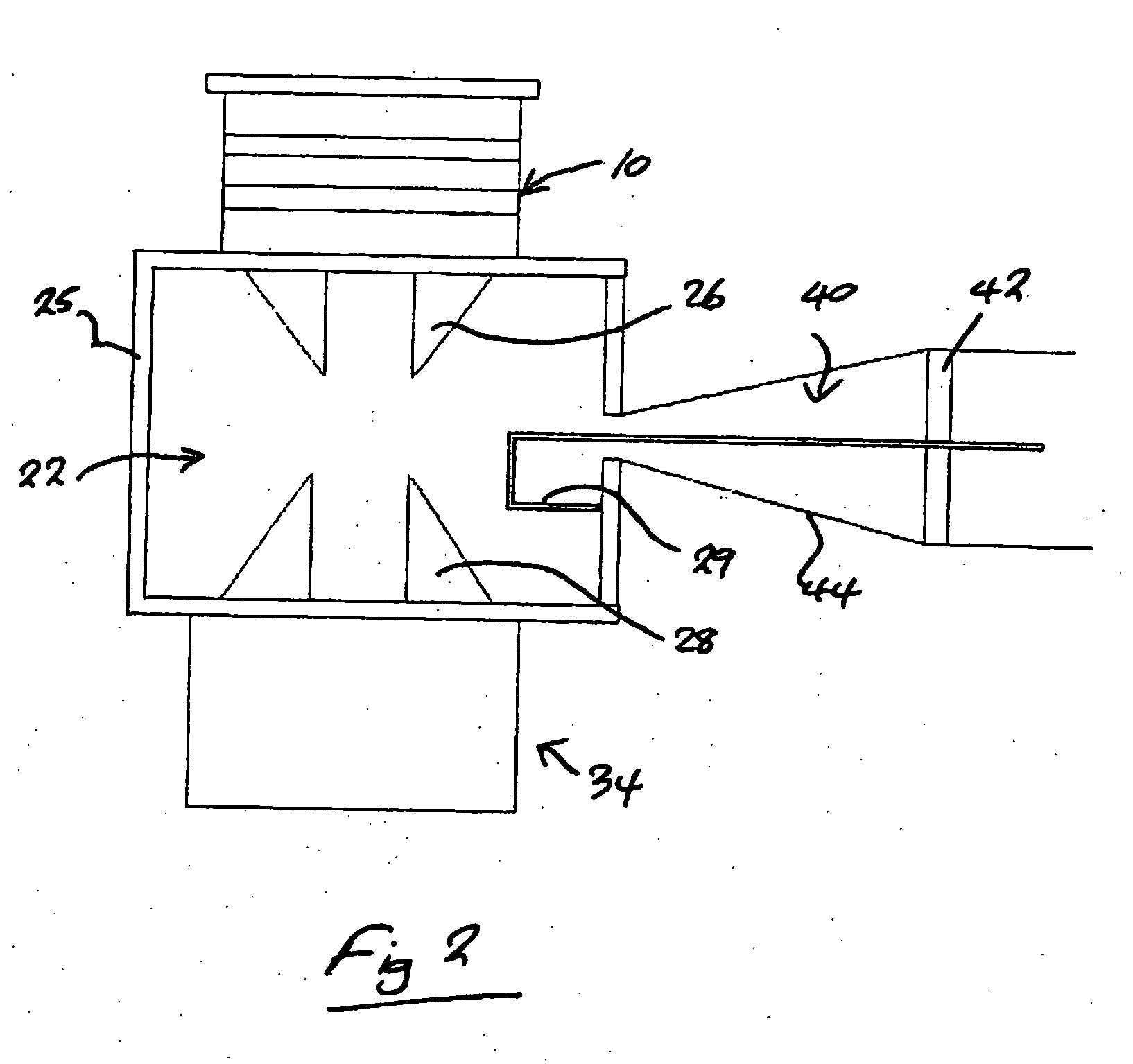

[0022] The embodiment of the invention described is an Inductive Output Tube (IOT). However, it would be appreciated to the skilled person that the invention applies equally to other linear beam devices such as travelling wave tubes and Klystrons.

[0023] The embodiment of the present invention addresses the problems associated with the installation or removal of linear beam tubes containing integral output cavities and feeders, (or sidearms), from their associated circuit assemblies. This is achieved by pivoting those parts of the circuit assembly that would otherwise foul on the tube feeder out of the path of the tube for the duration of the installation or removal process.

[0024] The embodiment of the present invention avoids the possible need to break electrical connections, and makes tube installation / extraction a one man process while also ensuring that the magnetic axis and precision of the magnetic frame is not compromised by the complete removal of major components.

[0025] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com