Fuel cell system comprising modular design features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

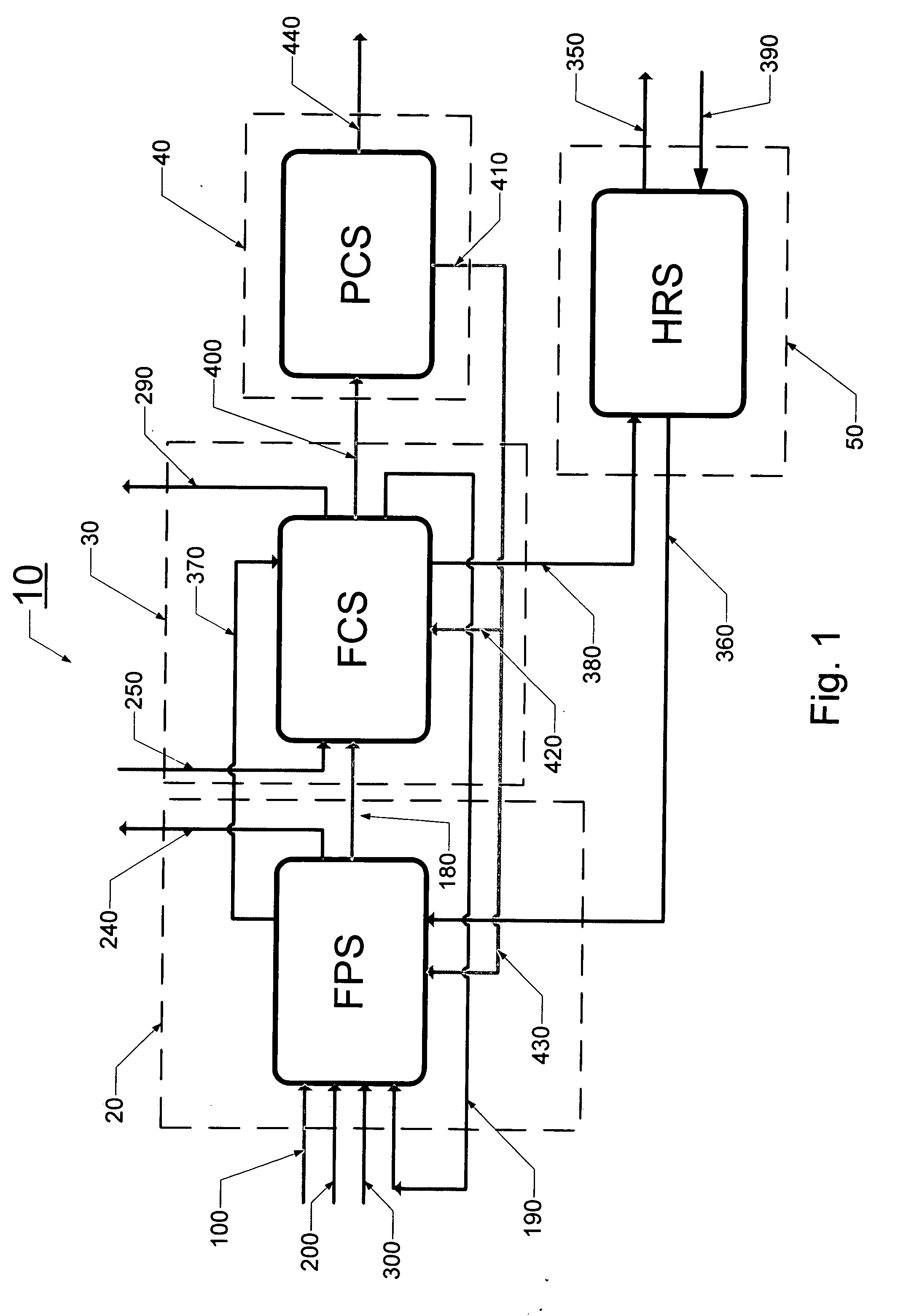

[0025]FIG. 1 shows a fuel cell power system 10 comprising of four major subsystems, namely, a fuel processor subsystem (FPS) 20, a fuel cell subsystem (FCS) 30, a power conditioning subsystem (PCS) 40 and a heat recovery subsystem (HRS) 50. If designed and manufactured separately, FPS 20, FCS 30 and PCS 40 can be independent devices for hydrogen production and pure hydrogen based fuel cell power generators. When combined in a way such as shown in FIG. 1, it becomes an integrated fossil fuel based fuel cell power system for either small or large stationary applications. When they are further integrated with HRS 50, it can provide both heat and power for users. This provides a modular design at the system level.

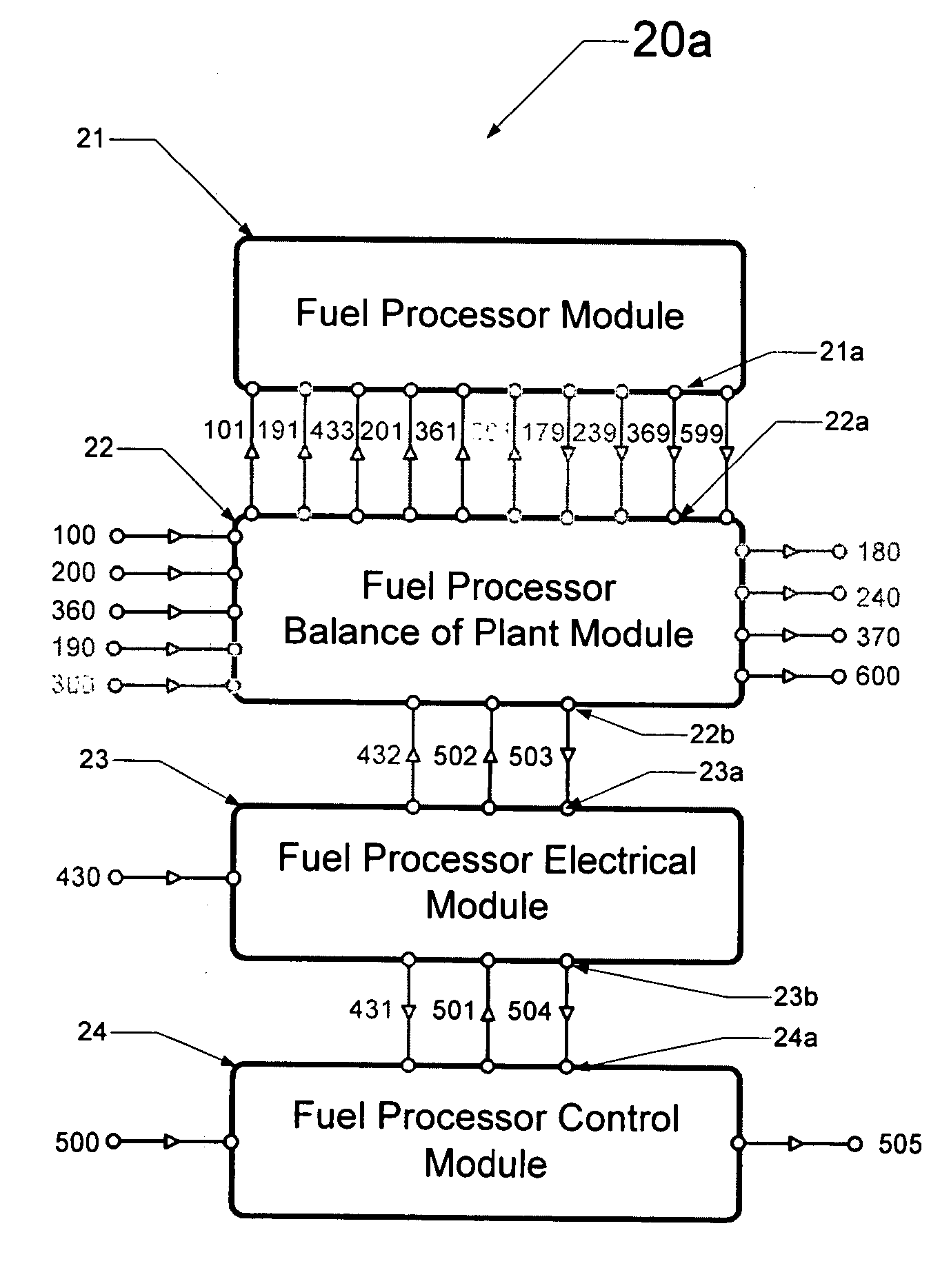

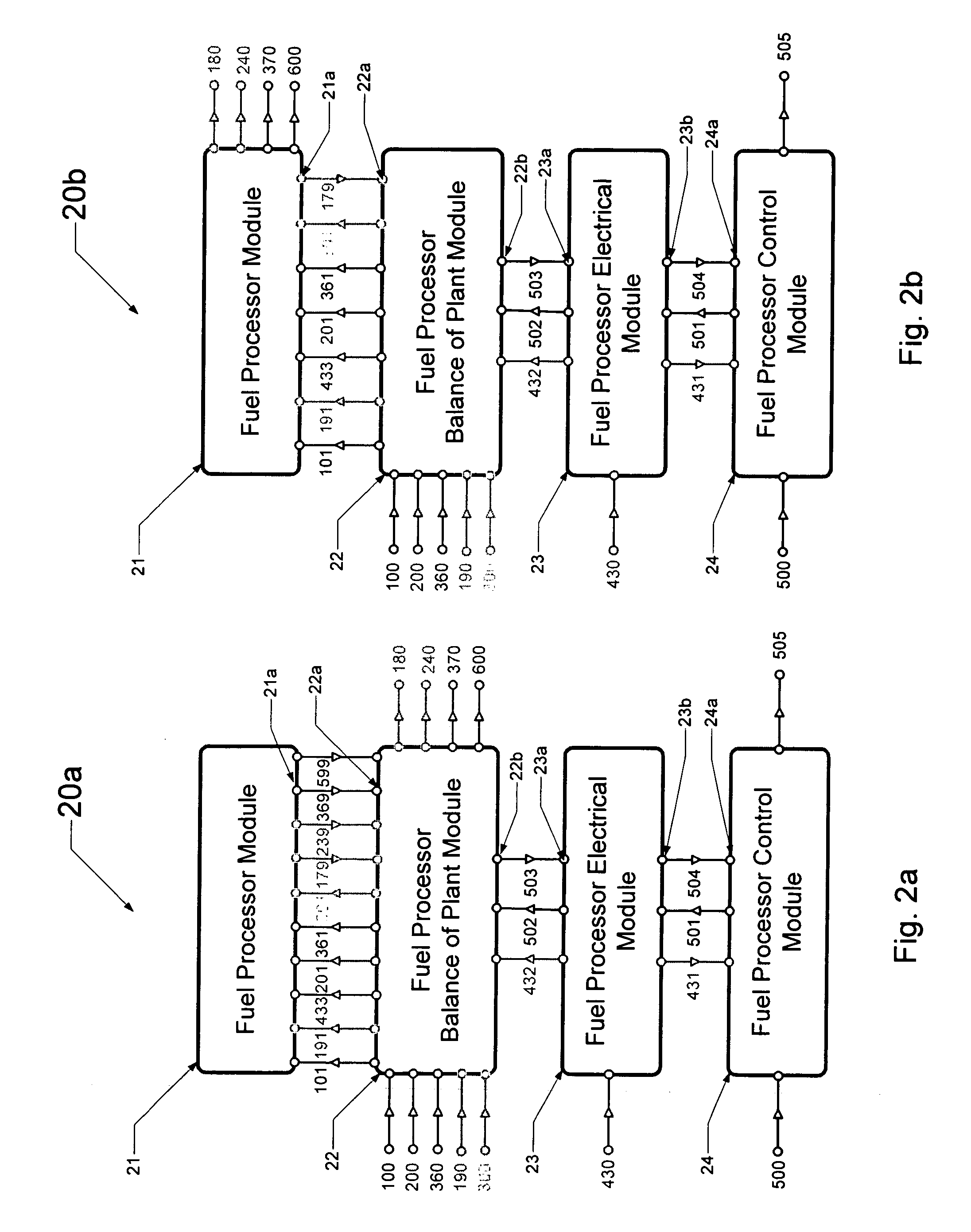

[0026] For the fuel processor subsystem module, as schematically illustrated in FIG. 2a and FIG. 2b, it further consists of four general sub-modules, namely, [0027] a fuel processor module 21, in which all fuel processor sub-components such as steam reformer, shift reactor, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com