Methods for improving discoloration resistance of pulp and pulp improved in discoloration resistance

a technology of discoloration resistance and discoloration resistance, which is applied in the field of improving the discoloration resistance of pulp. it can solve the problems of yield loss in bleached pulp or strength loss in pulp fibers, and uv absorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

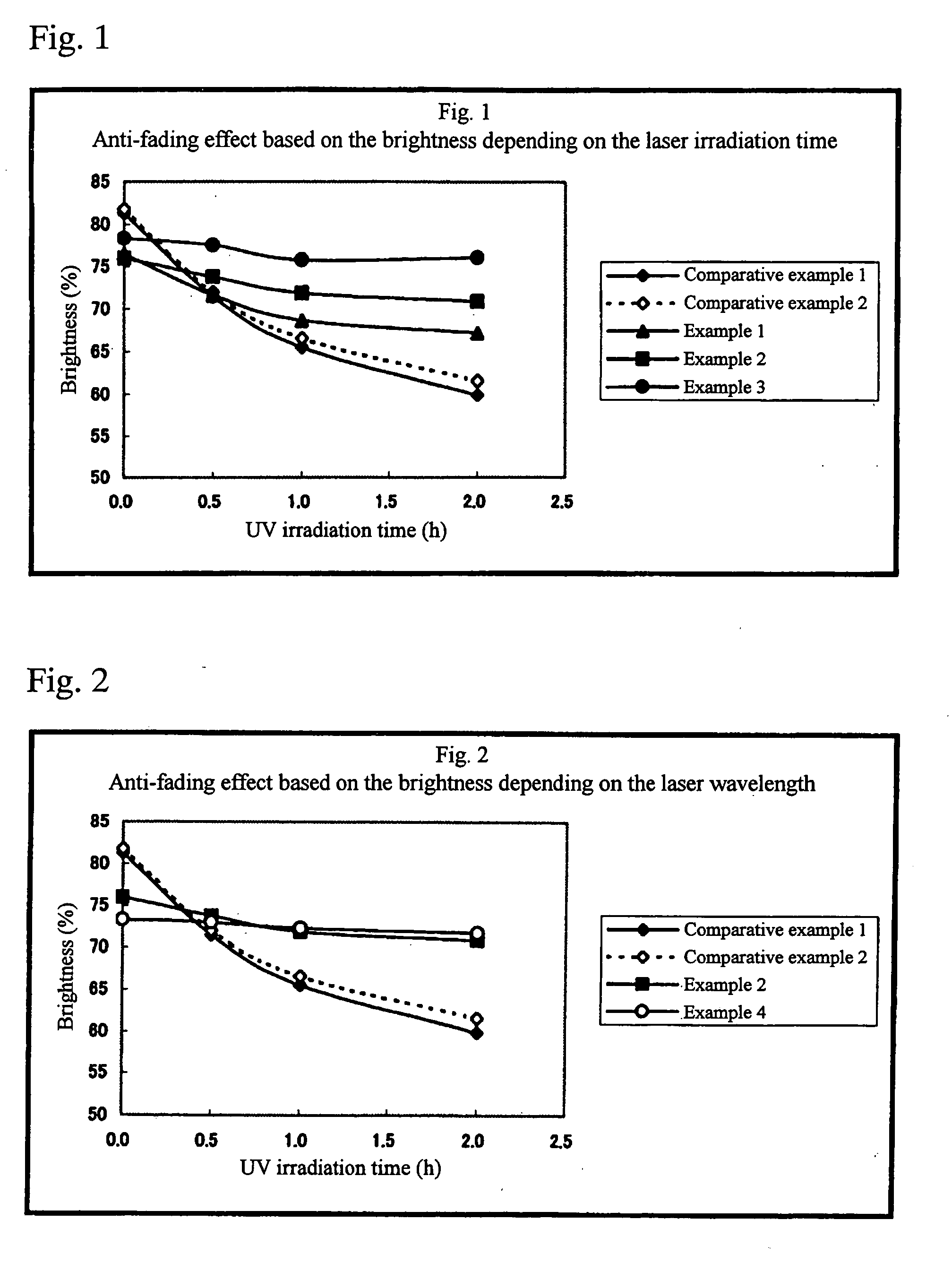

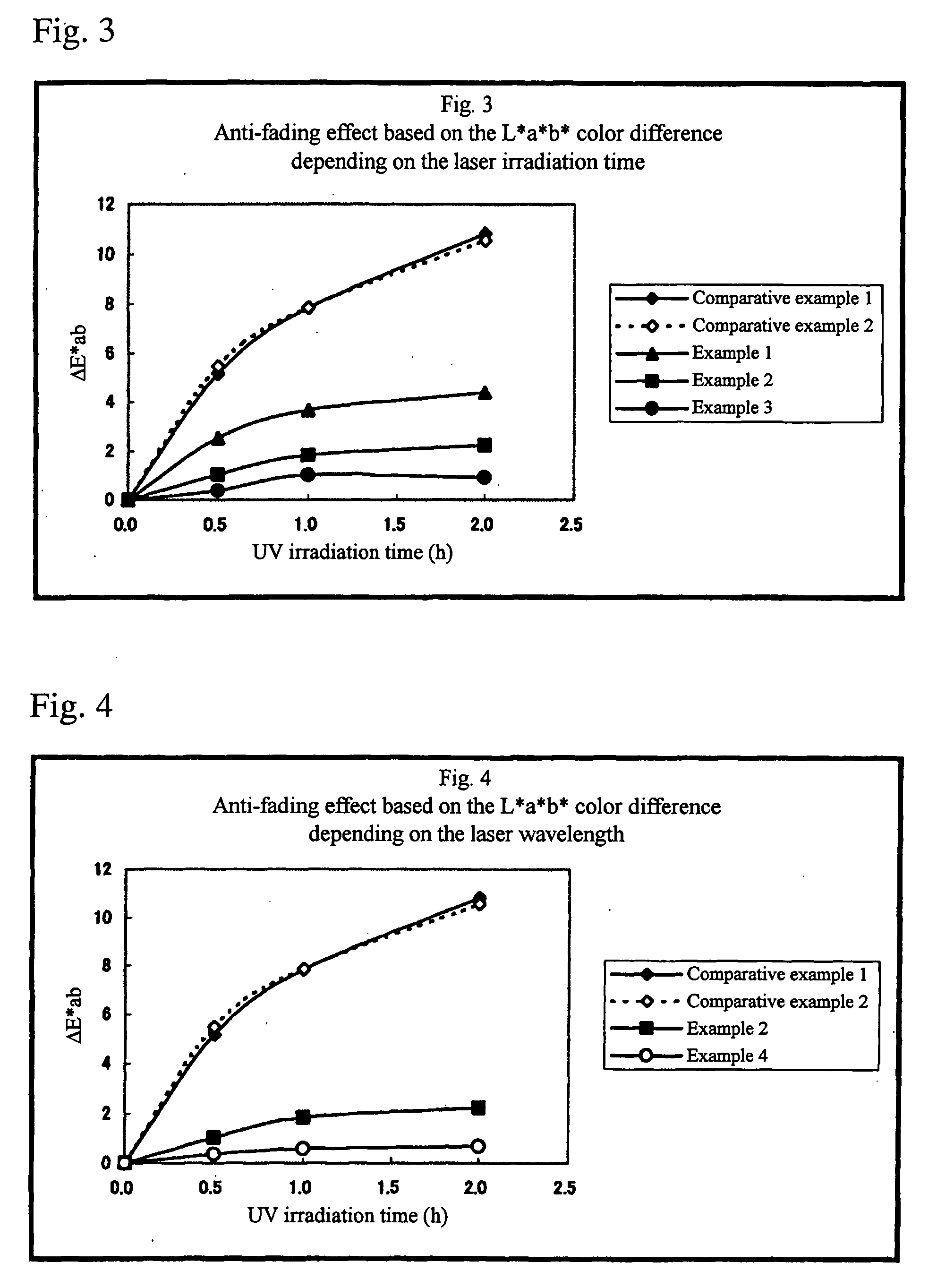

example 1

[0045] A hand-made paper containing a bleached MP and a bleached CP made from coniferous wood in a ratio of 1:1 (200 cm2, basis weight 60 g / m2) was divided into four portions to prepare samples for laser processing. These samples were immersed in a 6% aqueous sodium borohydride (w / v) solution and then mounted on a glass plate. At this point, the impregnation level of sodium boron hydride was 18% solids by weight on the basis of the weight of pulp solids. The samples were irradiated with KrF excimer laser at 40 mJ / cm2 / pulse, 5 Hz for 10 minutes. After completion of laser irradiation, the sample was washed with water and dried in a cylinder dryer. A fading test was performed using a xenon lamp weather meter. The samples were irradiated with UV light generated from the xenon lamp for 0.5, 1.0, and 2.0 hours, after which ISO brightness [JIS 8148] and L*a*b* color difference (delta E*ab) [JIS Z 8701] were determined. The fading test was performed at a black panel temperature of 63° C., h...

example 2

[0046] The same procedure as in Example 1 was performed except that the irradiation time of KrF excimer laser was changed to 20 minutes.

example 3

[0047] The same procedure as in Example 1 was performed except that the irradiation time of KrF excimer laser was changed to 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| Kappa number | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com