Control of respiratory oxygen delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

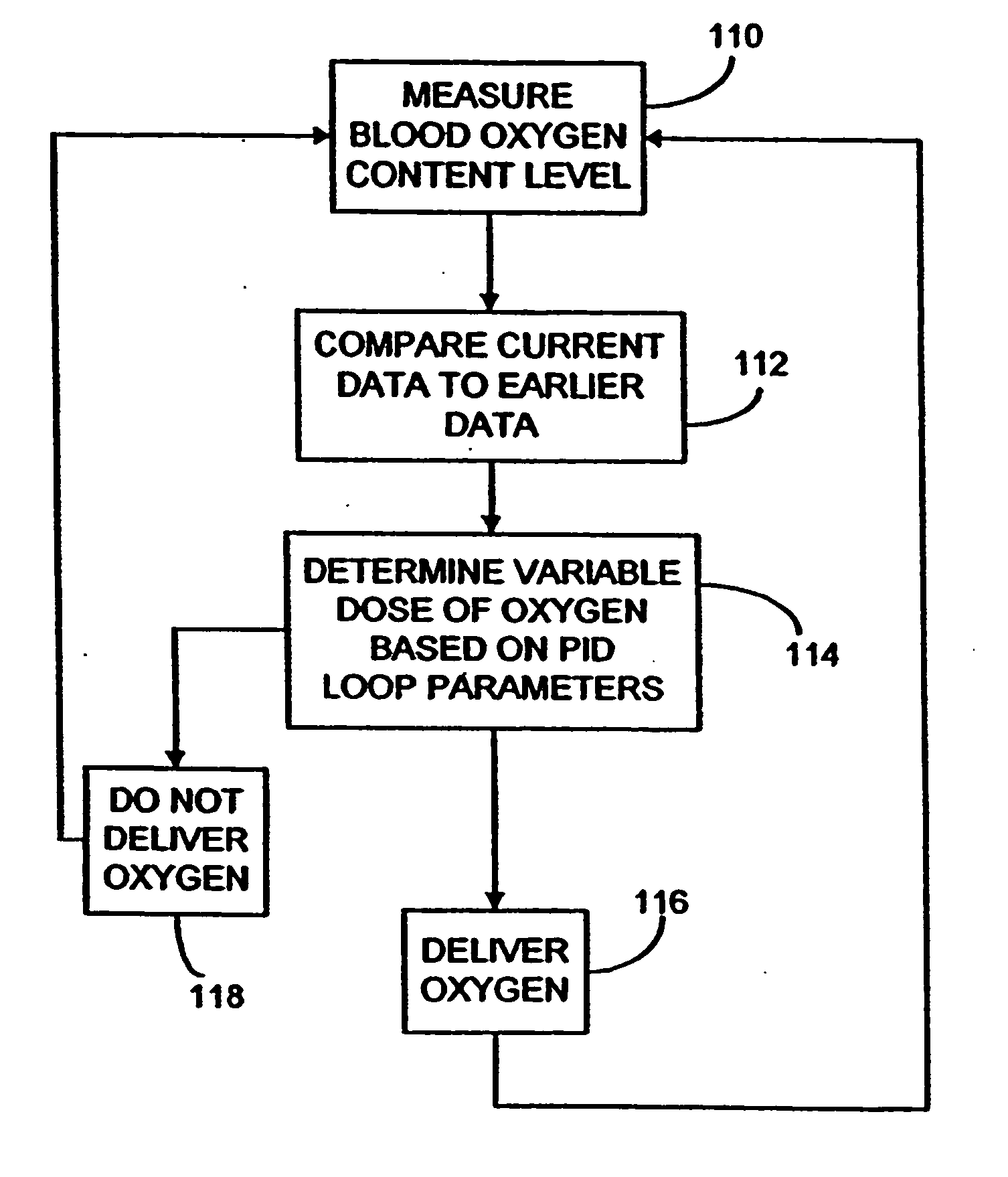

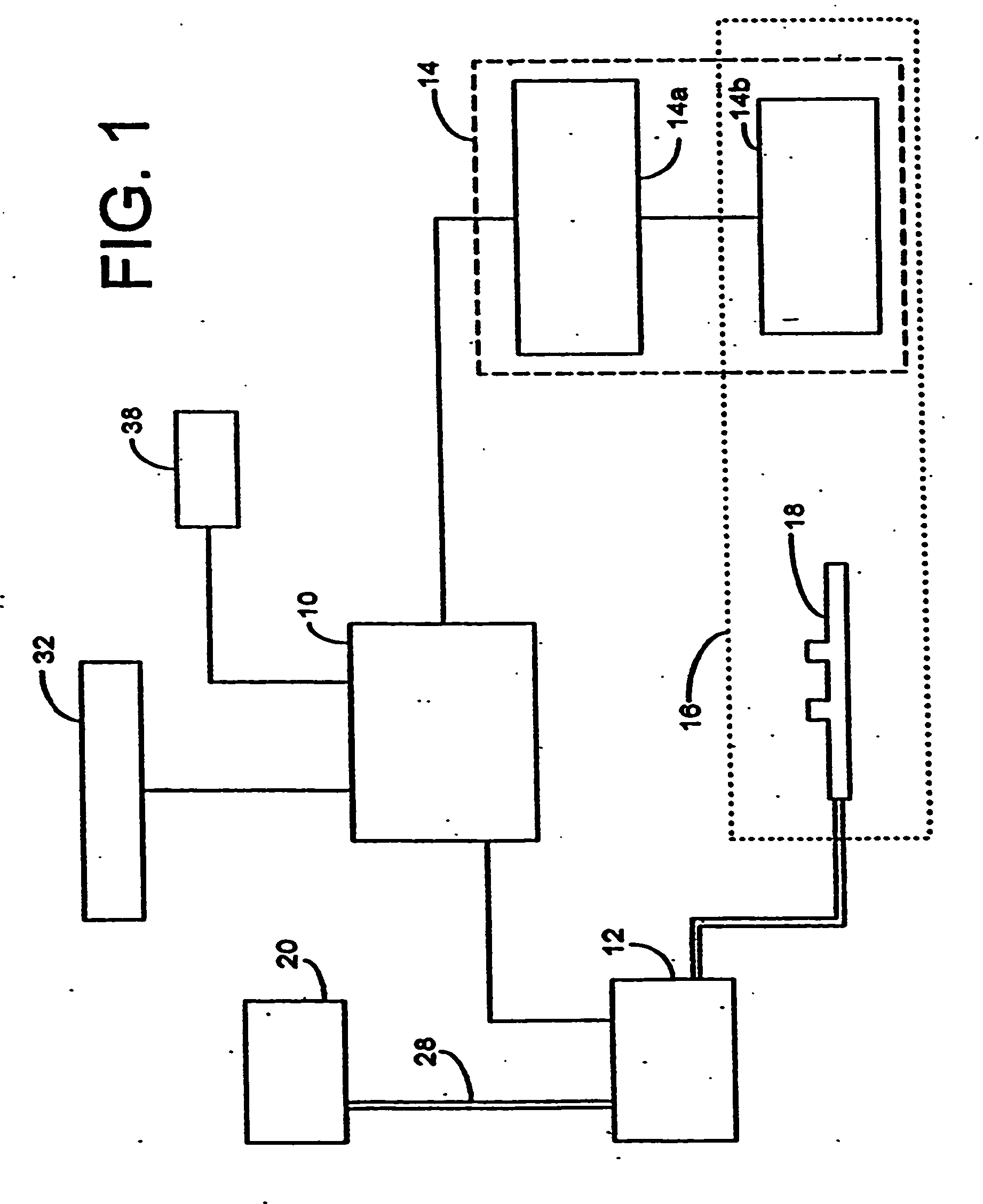

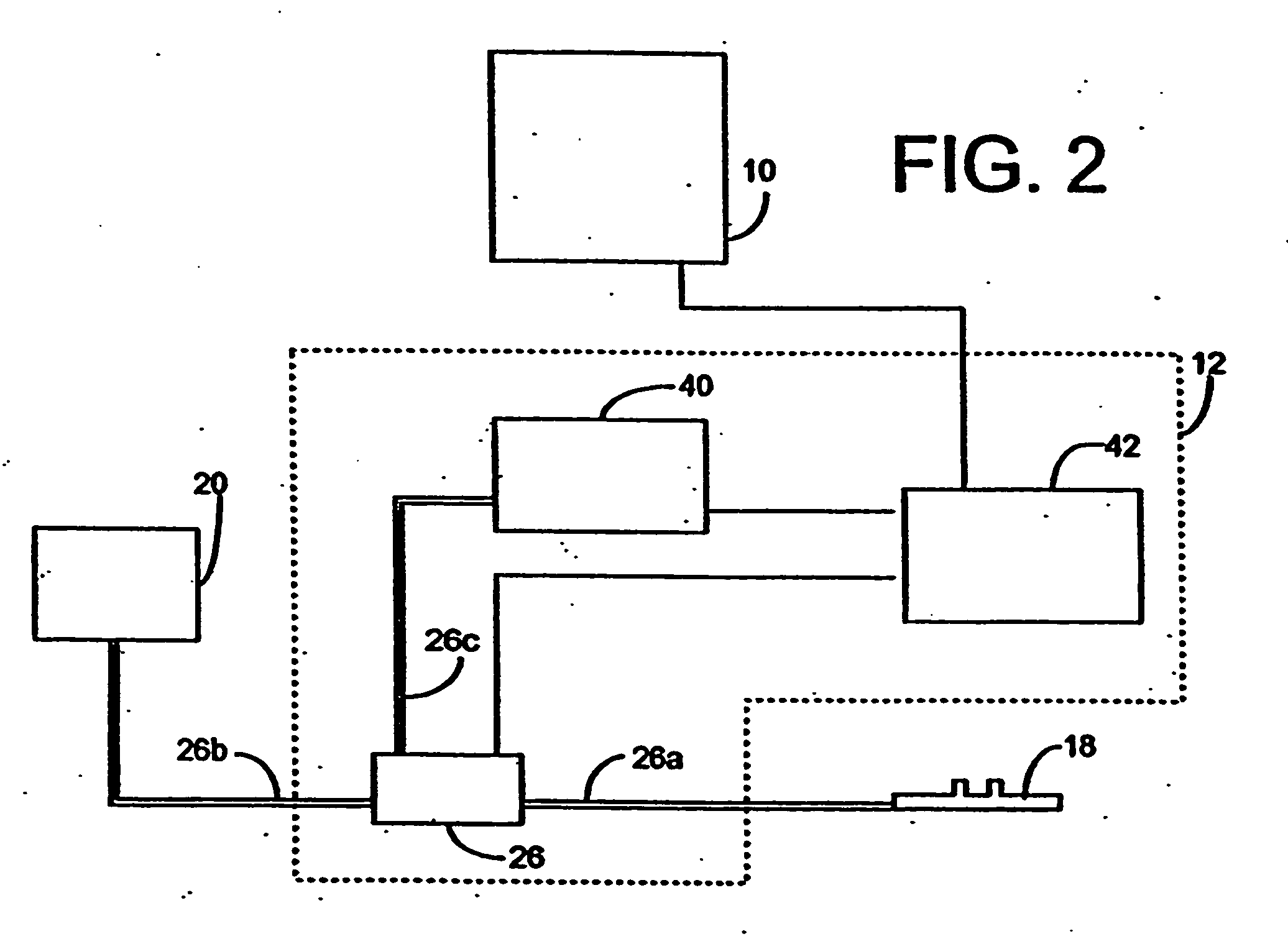

[0031] As described above, the present invention provides demand respirating oxygen supply methods and apparatus for use in sub-acute care which maintain healthy blood oxygen saturation in patients by controlled dosing of oxygen with a measured response to the patient's actual blood oxygen content. The dosing can be provided by simple on / off control over the delivery of oxygen or the amount of oxygen delivered to the patient with each inhalation can be varied in response to the patient's need as determined by a more sophisticated control scheme, such as a proportional-integral-derivative (PID) loop control algorithm, that utilizes the difference between the patient's measured blood oxygen content level and a desired or target blood oxygen content level.

[0032] The systems and methods of the present invention are particularly directed at patients receiving supplemental oxygen in a sub-acute care environment, more preferably in a residential setting. The needs and considerations of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com