Composition and method for preparing biocompatible surfaces

a biocompatible surface and composition technology, applied in the field of biocompatible surfaces, can solve the problems of surface induced thrombosis (clot formation), adverse reactions to medical devices, thinness of polymer coatings, etc., and achieve the effects of reducing throughput time, reducing the activity of each layer, and reducing the thickness of the polymer coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

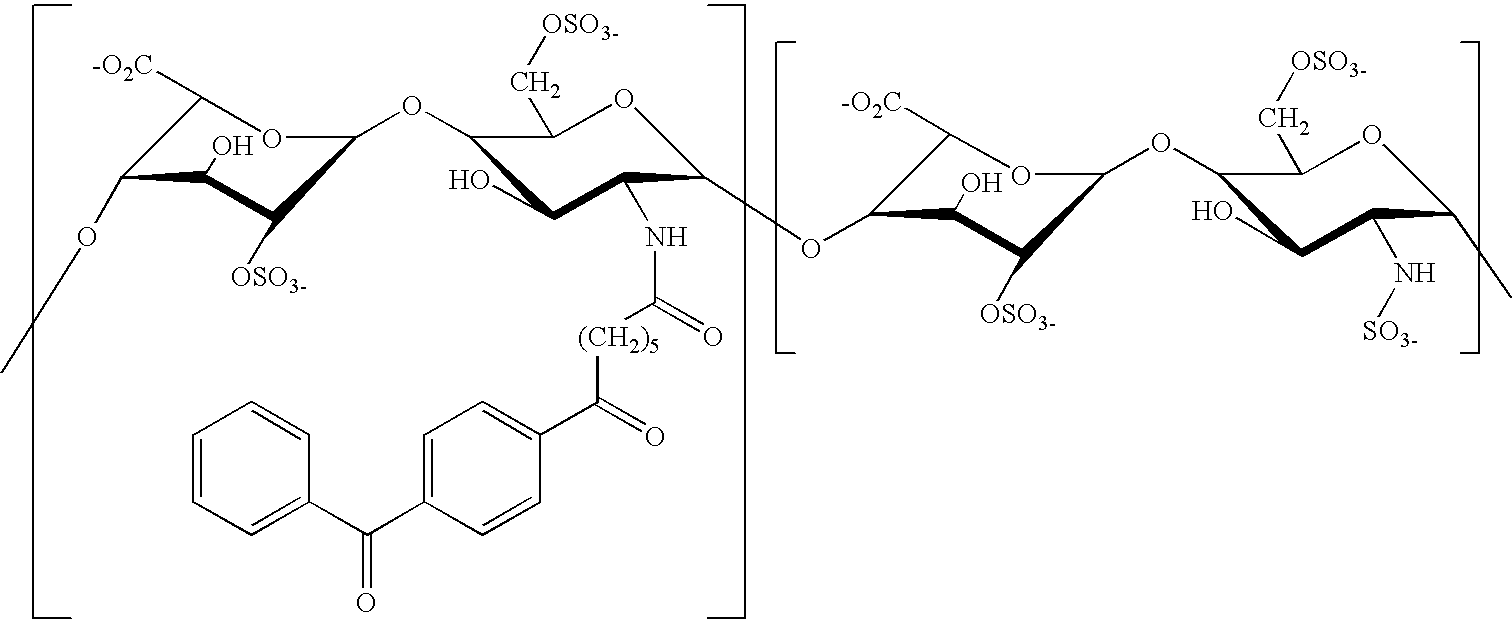

[0241] Coating composition premixtures containing pBMA (poly(butyl)methacrylate); and photo-heparin (Compound I) were prepared and coated on stainless steel stents, demonstrating that a medical article having a coating containing an adhesion polymer and having biocompatible properties can be prepared in a process that requires a minimum number of steps.

[0242] Solutions of pBMA at a concentration of 10 mg / ml in 90% THF, 10% H2O, and a solution of pBMA at a concentration of 10 mg / ml in 100% THF was prepared. Solutions of photo-heparin at concentrations of 5 mg / ml and 10 mg / ml in 90% THF 10% H2O, and a solution of photo-heparin at 50 mg / ml in H2O was prepared. For a control, a solution of heparin (non-photo) at 50 mg / ml in H2O was prepared. At these concentrations the pBMA and photo-heparin did not precipitate out of solution. The solutions of pBMA and photoheparin were mixed in order to prepare mixtures having the following concentrations of pBMA and photo-heparin:

[0243] (A) 5 mg / ml...

example 2

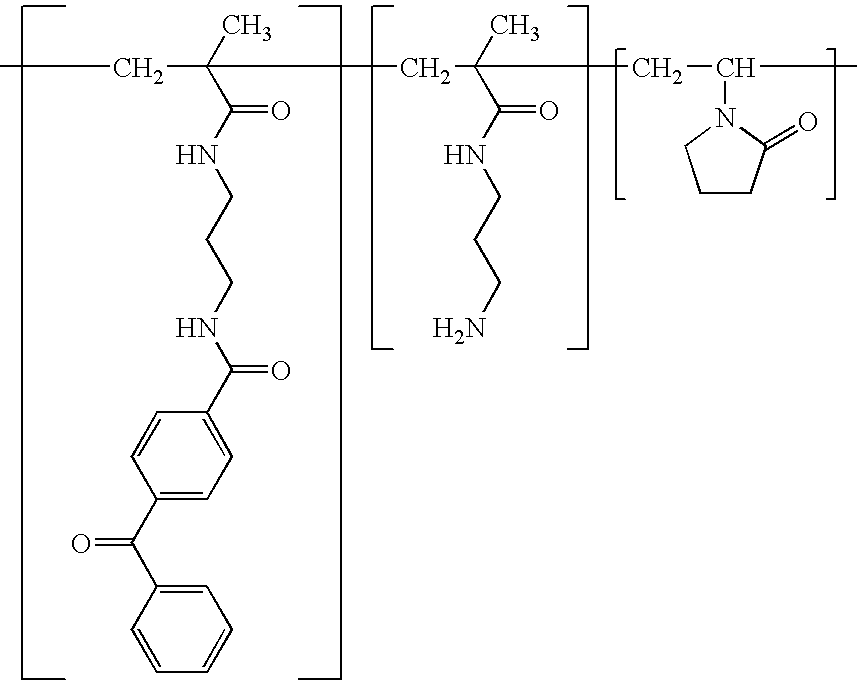

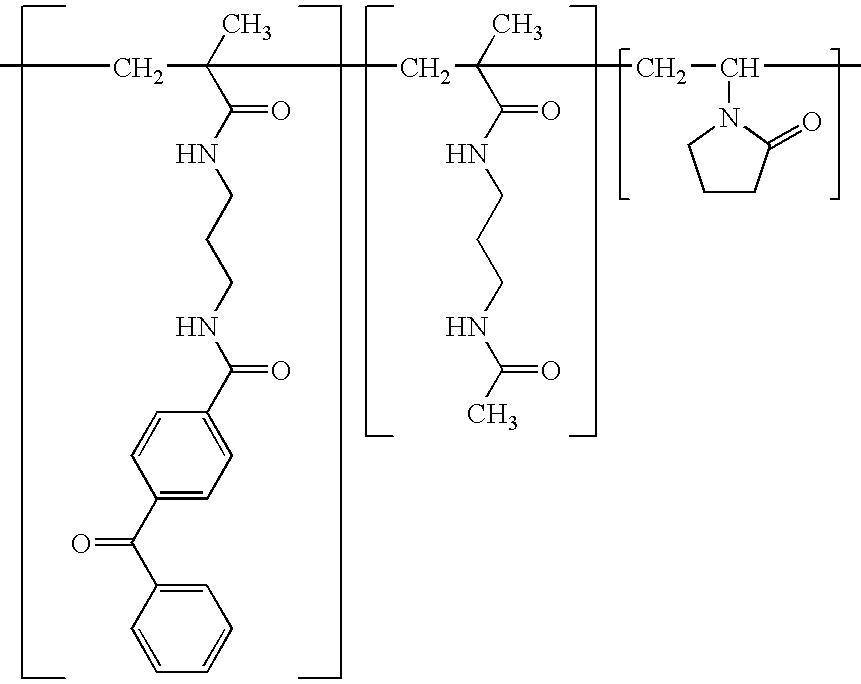

[0248] Coating composition premixtures containing pBMA, photo-heparin, and acetylated-photo-PVP (Compound III) were prepared and coated on stainless steel stents. The stents had coatings that demonstrated excellent biocompatibility properties.

[0249] A mixture of pBMA at a concentration of 5 mg / ml, photo-heparin at 2.5 mg / ml, and photo-polyvinylpyrrolidone at 0.25 mg / ml in 90% THF and 10% H20 was prepared (Table 2).

[0250] Stents were coated using the spray coating apparatus having a pair of rollers and an ultrasonic nozzle (as described herein) at rate of 0.03 ml / min, 20% speed, and 1 psi. 20-50 μg of mixture was coated onto each stent.

[0251] After the coating was performed the stents were: not subject to an irradiation step (2-A1 / A2), subject to UV irradiation for 45 seconds at 6-8 mW / cm2 using a 324 nm filter (2-A3 / A4), or subject to UV irradiation in addition to receiving a top coat of photo-heparin (2-A5 / A6). A heparin top coat was applied to the stents (50 mg / ml photo-heparin...

example 3

[0254] Coating composition premixtures containing photo-heparin and photo-PVP were prepared and subject to UV irradiation. The irradiated premixtures of photo-heparin and acetylated photo-PVP were then added to a solution of pBMA and the resulting mixtures were then coated on stents. Stents having surface heparin activity were able to be prepared without directly irradiating the stent surface.

[0255] In addition, the coating compositions were applied in an improved coating solution that included isopropanol alcohol.

[0256] A miscibility test was first performed to determine if isopropanol alcohol is suitable as a common liquid for preparing a mixture of pBMA, photo-heparin, and acetylated photo-PVP. pBMA was dissolved at a concentration of 10 mg / ml in 80% isopropanol (IPA), 20% THF. Photo-heparin was dissolved at a concentration of 10 mg / ml in 90% EPA, 10% H20. Acetylated photo-PVP was dissolved at a concentration of 10 mg / ml in 100% IPA. To 7 mls of IPA was added each 1 ml of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com