Method of providing cured coating films free of popping defects

a coating film and defect-free technology, applied in the field of coating compositions, can solve the problems of difficult to predict the degree of resistance to environmental etching, and difficult to devise environmentally sensitive coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

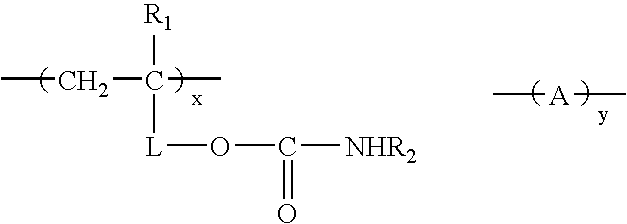

Method used

Image

Examples

example 1

Part a

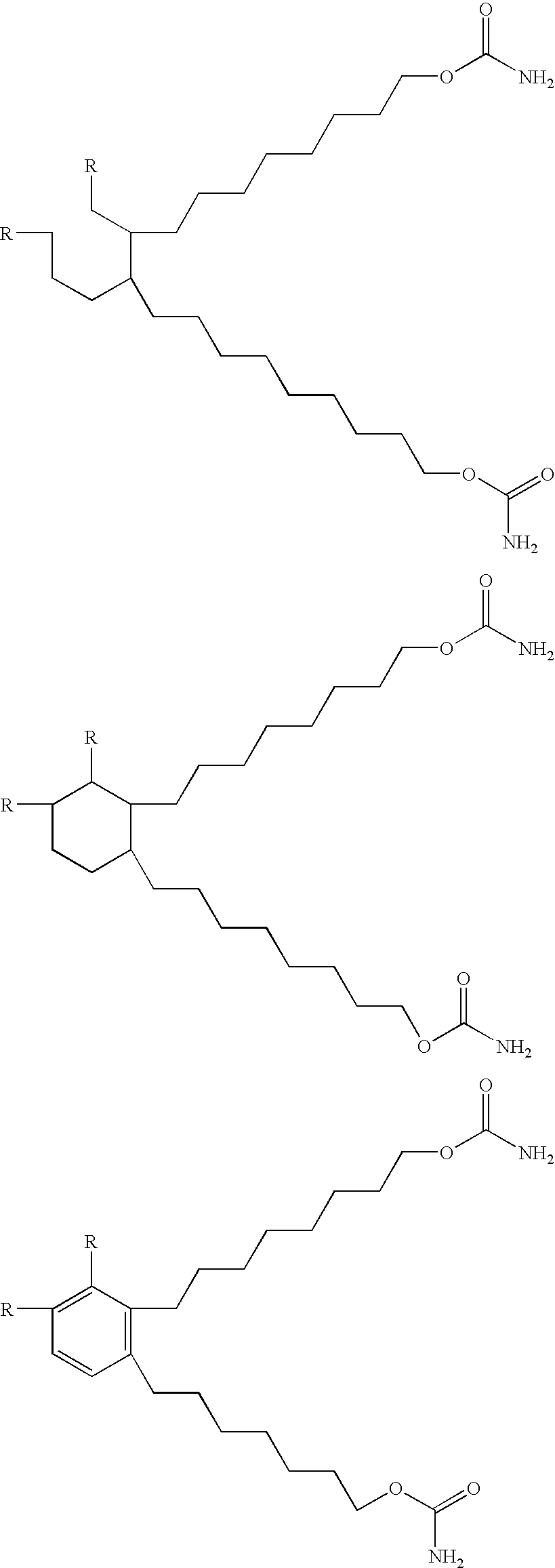

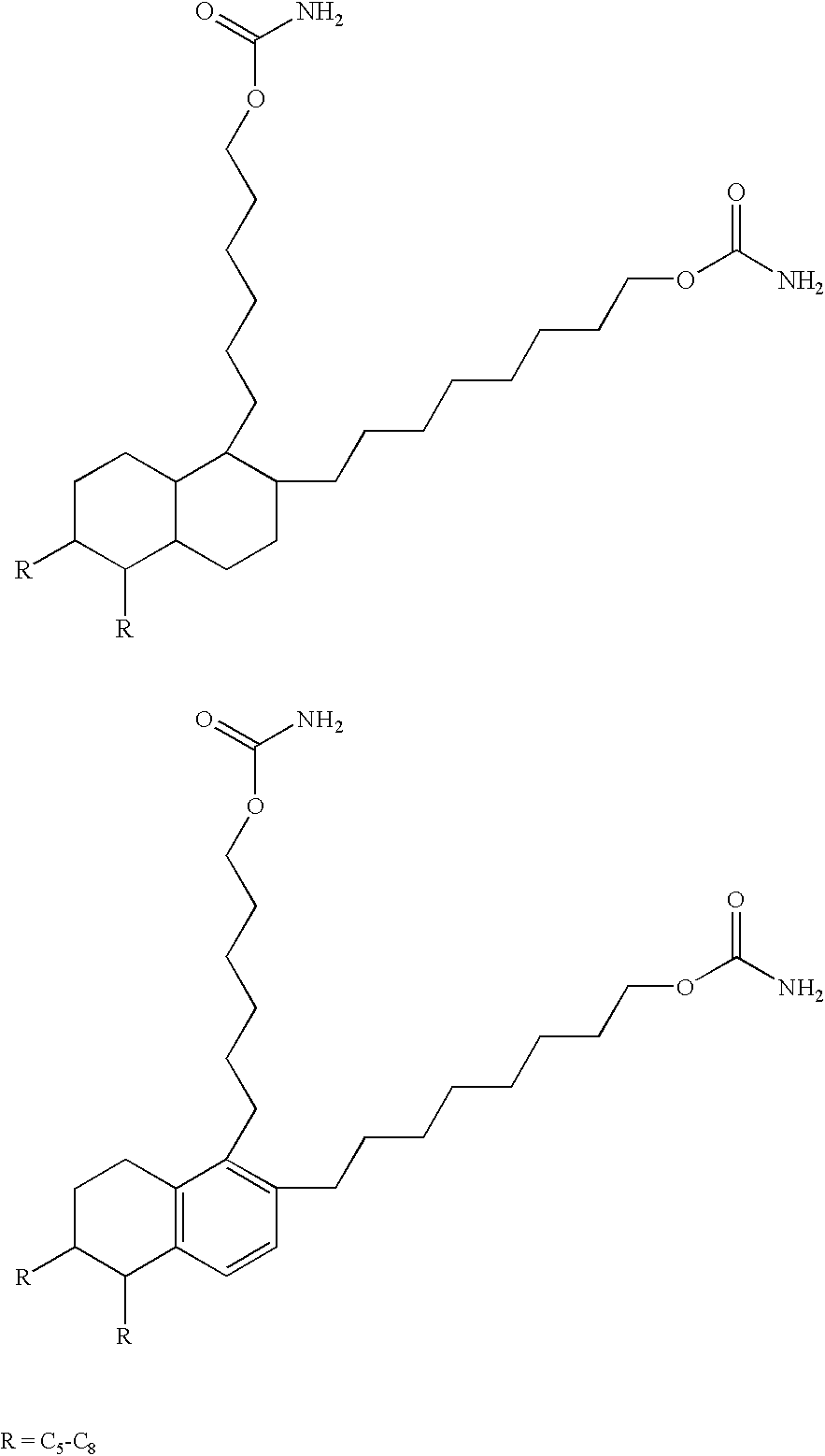

Preparation of an Anti-Popping Component (a)

[0152] A mixture of 59.4 parts of Pripol™ saturated fatty acid dimer diol, (commercially available from Uniqena), 20.1 parts methyl carbamate, 20.4 parts toluene and 0.09 parts of dibutyl tin oxide are heated to reflux. Once at reflux, the methanol is removed from the reaction mixture and the toluene is allowed to return to the reaction mixture. After 96% of the hydroxy groups are converted to primary carbamate groups, the excess methyl carbamate and toluene are removed by vacuum distillation. A dicarbamate functional anti-popping component (a) was obtained.

Part b

Preparation of Organic Binder Component

[0153]

MaterialAmountAnti-popping component92.2(a) from part (a)Acrylic dispersing resin168.8AMP solution21.7Deionized water144.6

1The acrylic dispersing resin is a 67% NV resin in propylene glycol propyl ether, and has a acid number of 48 and a hydroxy number of 64.

2AMP solution is a 20% solution in deionized water of 2-amino-2-met...

example 2

Part a

Preparation of a Mixture Containing an Anti-Popping Component (a) and a Film-Forming Component (b)

[0158] A mixture of 30 parts of a tri-carbamate functional material as described in Example 1 of U.S. Pat. No. 5,336,566 but with all of the solvent removed and 70 parts of the anti-popping component (a) from Example 1, part a was mixed together. The mixture was stirred on a hot plate until a homogenous mixture was obtained.

Part b

Preparation of Organic Binder Component

[0159] Using the technique of Example 1, part b, an organic binder component was prepared using the following materials.

MaterialAmountMixture from Ex. 2, part b268.0Acrylic Dispersing resin4197.2AMP solutions56.8Deionized water480.4

4Same acrylic dispersing resin as used in Example 1.

5Same AMP solution as used in Example 1.

Part c

Preparation of Waterborne Clearcoat

[0160] Using the technique of example 1, part c, a waterborne clearcoat was produced using the following materials.

MaterialAmount (on paint NV)O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com