High purity perfluoroelastomer composites and a processes to produce the same

a perfluoroelastomer composite and high purity technology, applied in the direction of coatings, emulsion paints, etc., to achieve the effect of minimizing corrosion, minimizing contamination, and eliminating metallic contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] An aqueous emulsion containing 10 g 8-CNVE [CF2═CF—O—(CF2)3—O—CF(CF3)—CN], 135 g deionized (DI) water and 5 g 20 wt % ammonium perfluorooctanoate (APFO) aqueous solution was prepared by using an Omini Mixer Homogenizer (Omini International Co.) for 5 minutes. This solution is designated as “stock solution A”.

[0044] Approximately 1500 g DI water, 300 g 20 wt % APFO aqueous solution and 16 g 8-CNVE were charged into an oxygen-free 4-liter reactor. Then, 190 g TFE and 300 g PMVE were added into the reactor. The reactor was then heated to 70° C. under 2285 KPa and the polymerization reaction was initiated by feeding 202 g ammonium persulfate (APS) aqueous solution (2 g APS dissolved in 200 g DI water) within 2 minutes. As the reaction pressure decreased to 1800 KPa, 105 g stock solution A with 120 g DI water and 20 g TFE were charged into the reactor within 3 minutes. Then, 150.5 g APS solution (0.5 g APS dissolved in 150 DI water) was fed into the reactor within 1 minute. As th...

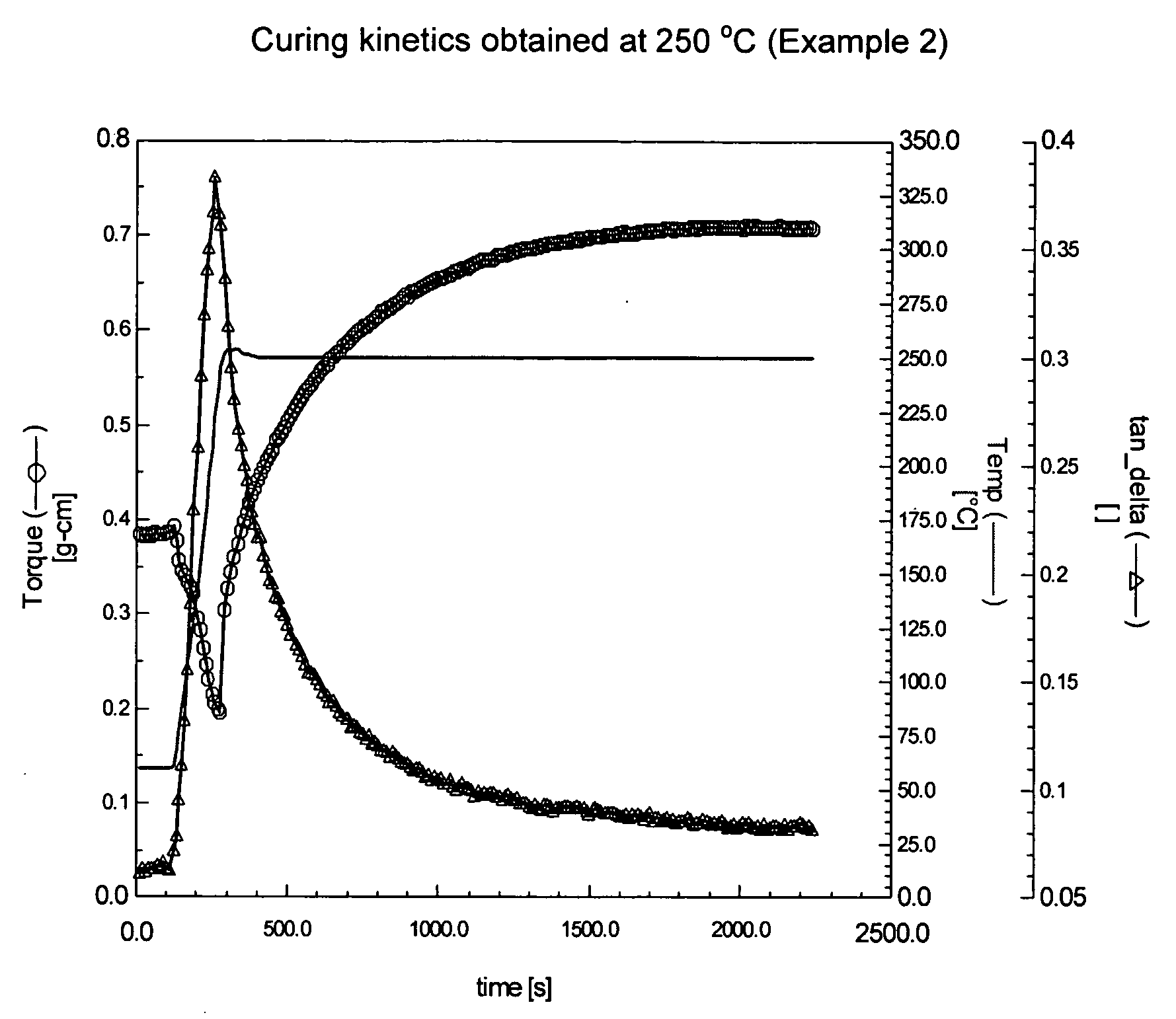

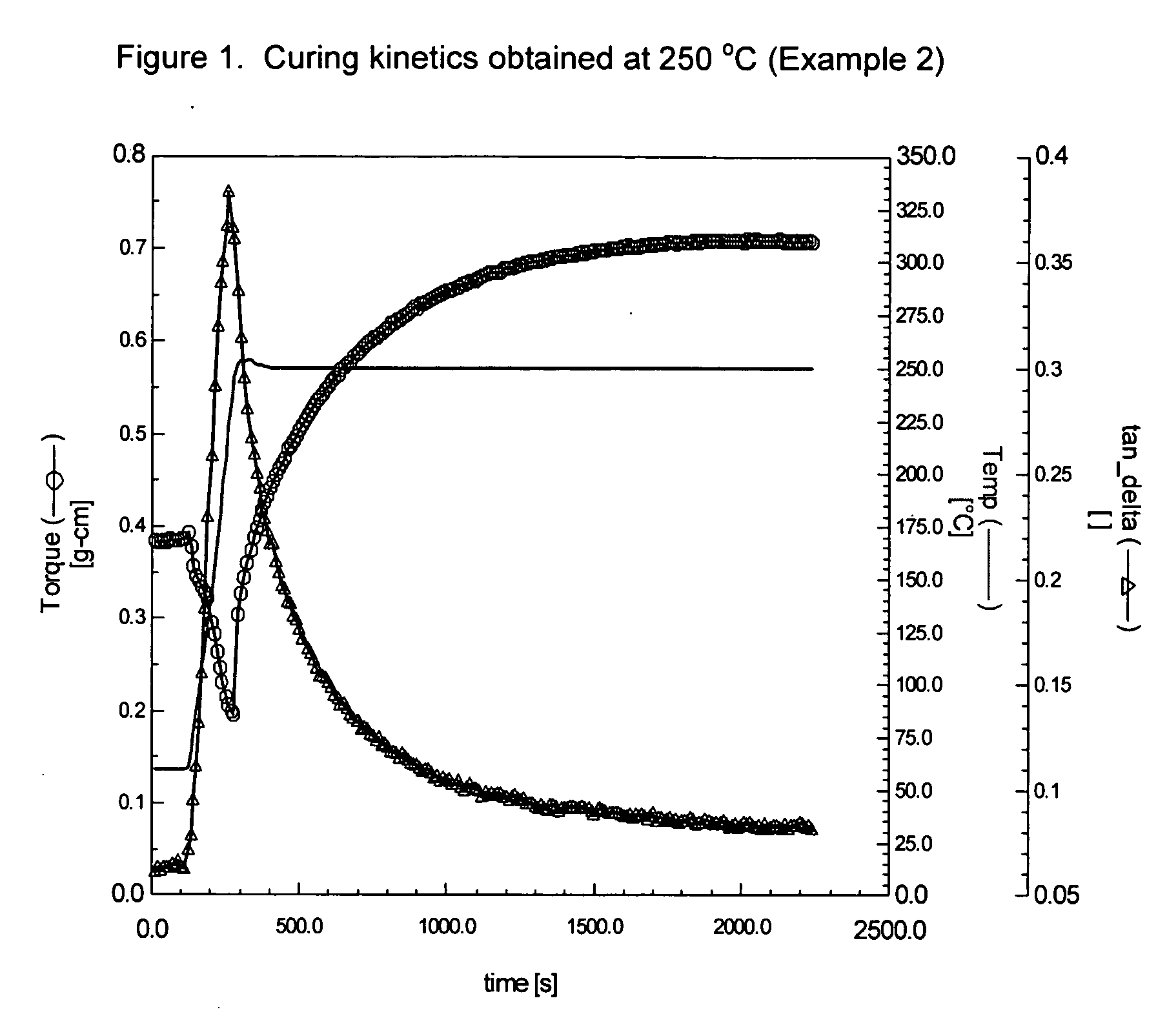

example 2

[0049] An aqueous solution containing 10 g 8-CNVE [CF2═CF—O—(CF2)3—O—CF(CF3)—CN], 136 g DI water and 4 g of 20 wt % APFO aqueous solution was prepared by using an Omini Mixer Homogenizer for 5 minutes. This solution is designated as “stock solution B”.

[0050] Approximately 1500 g DI water, 300 g 20 wt % APFO aqueous solution and 16 g 8-CNVE were charged into an oxygen-free 4-liter reactor. Then, 190 g TFE and 320 g PMVE were added into the reactor. The reactor was then heated to 70° C. under 2347 KPa and the polymerization reaction was initiated by feeding 200.5 g APS aqueous solution (0.5 g APS dissolved in 200 g DI water) within 1 minute. As the reaction pressure decreased to 1900 KPa, 105 g stock solution B with 120 g DI water and 20 g TFE were charged into the reactor within 2 minutes. As the reaction pressure decreased to 1700 KPa, 45 g stock solution B with 150 g DI water and 20 g TFE were charged into the reactor within 2 minutes. The polymerization reaction was stopped after...

example 3

[0056] An aqueous solution containing 10 g 8-CNVE [CF2═CF—O—(CF2)3—O—CF(CF3)—CN], 480 g DI water and 10 g 20 wt % APFO aqueous solution was prepared by using an Omini Mixer Homogenizer for 5 minutes. This solution is designated as “stock solution C”.

[0057] Approximately 1500 g DI water, 300 g 20 wt % APFO aqueous solution and 16 g 8-CNVE were charged into an oxygen-free 4-liter reactor. Then, 260 g TFE and 300 g PMVE were added into the reactor. The reactor was then heated to 70° C. under 2584 KPa and the polymerization reaction was initiated by feeding 200.2 g APS aqueous solution (0.2 g APS dissolved in 200 g DI water) within 1 minute. Then, stock solution C was fed into the reactor as follows:

Time after reaction initiationStock solution C added(in minutes)(in grams)26016602860406051506160726083809810

[0058] As the reaction pressure decreased to 2120 KPa, 20 g TFE was charged into the reactor within 1 minute. Another 20 g TFE was added into the reactor within 1 minute as the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com