Weather proof dome to envelop outdoor objects, use of such a dome and a method for protecting outdoor objects

a weatherproof dome and outdoor object technology, applied in the direction of building roofs, constructions, building components, etc., can solve the problems of putting hard demands on the mechanical mounting bed, requiring a lot of material, and being expensive to produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

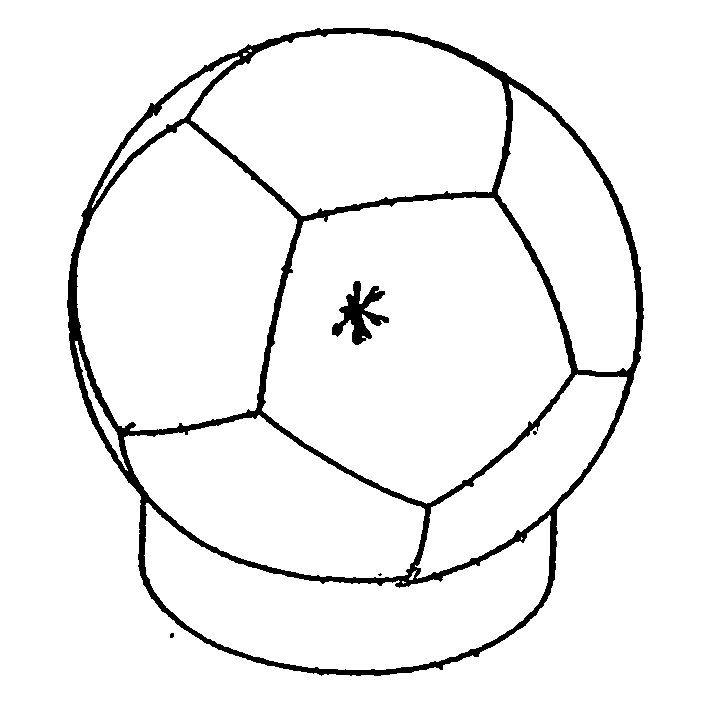

Image

Examples

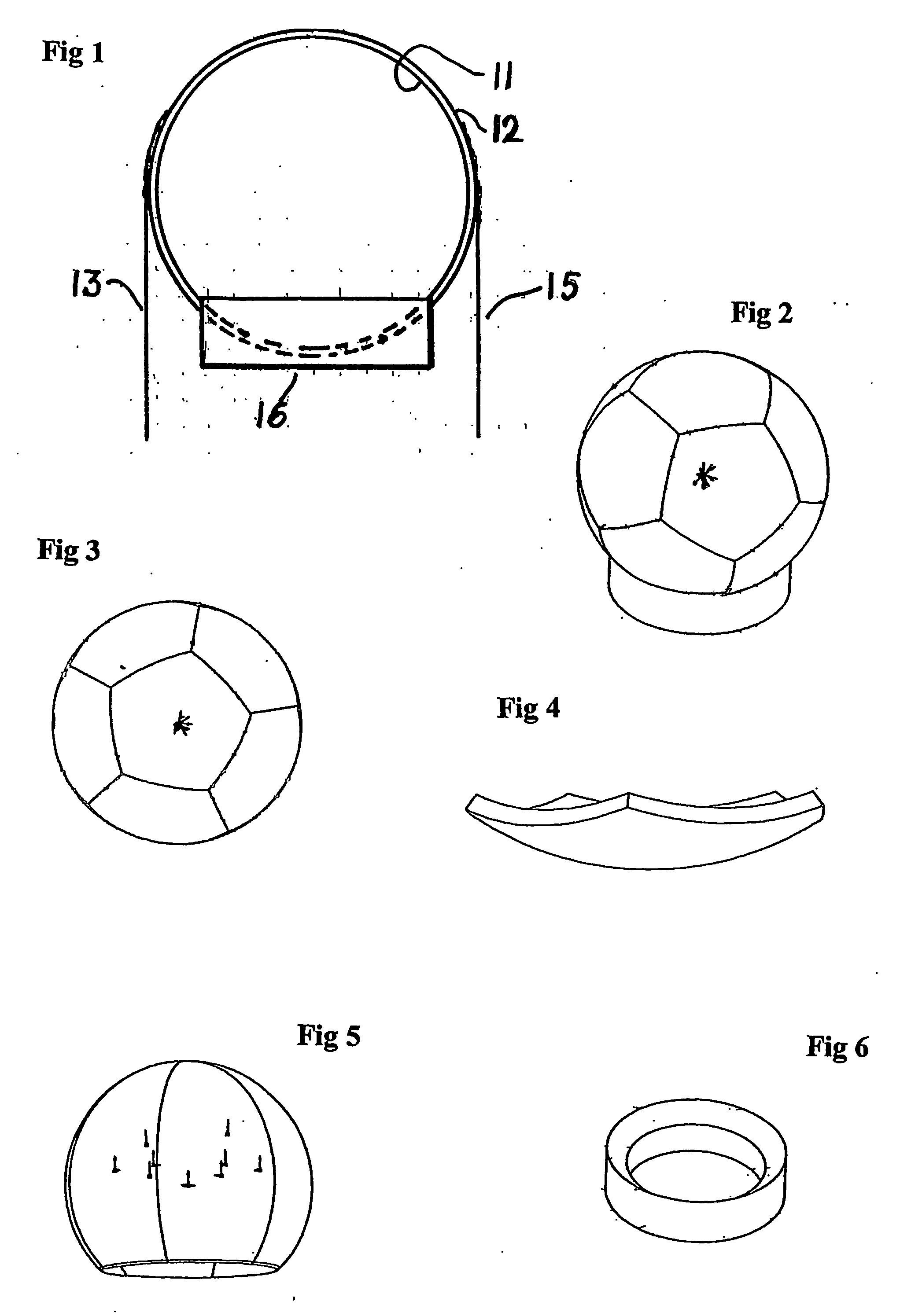

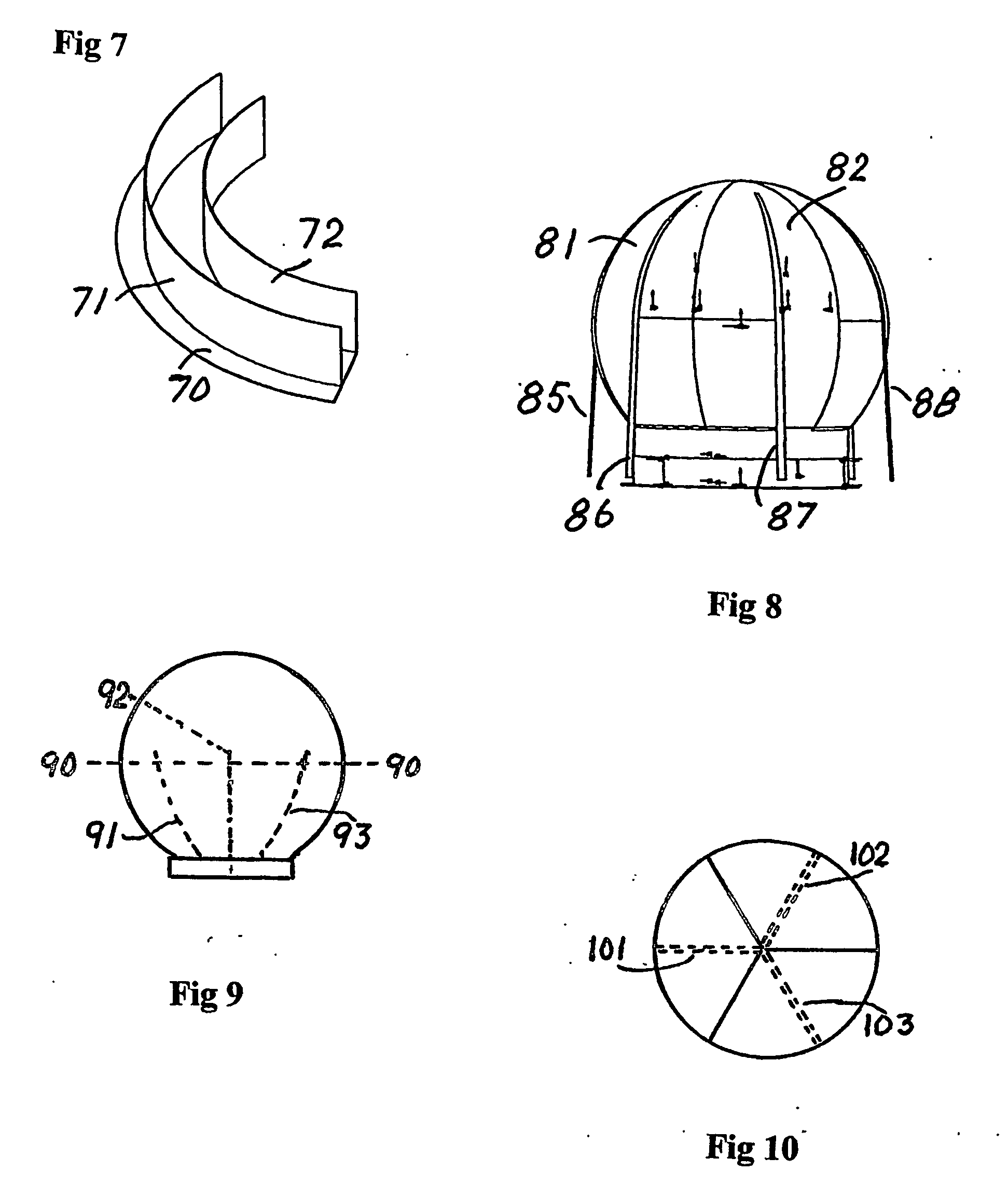

Embodiment Construction

[0015] This object has been achieved in that a dome of type specified in Claims no. 1 includes the specific features that the dome comprises an inner structure that withstands external pressure forces and an outer structure that through pulling forces on the outer structure holds the inner structure together, which outer and inner structures are not bonded to each other and at lest the outer structure is attachable to a base mount. The dome construction with an outer structure and an inner structure, not bonded to each other, meet all demands on a self-supporting dome—a weather proof unit—in terms of mechanical structure stiffness, rigidity, material stress, thermal insulation, signal gain attenuation and cross-polarisation etc. The inner structure offers required mechanical structure stiffness and rigidity by offering a geometrical momentum generated by thickness of the inner structure material, consisting of a large number of cells filled with air, giving acceptance to required el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com