Systems and methods for producing synthesis gas

a technology of synthesis gas and system, applied in the direction of combustible gas catalytic treatment, combustible gas production, sustainable manufacturing/processing, etc., can solve the problems of unwound hydrogen or power supply in the refinery, and achieve the effect of enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

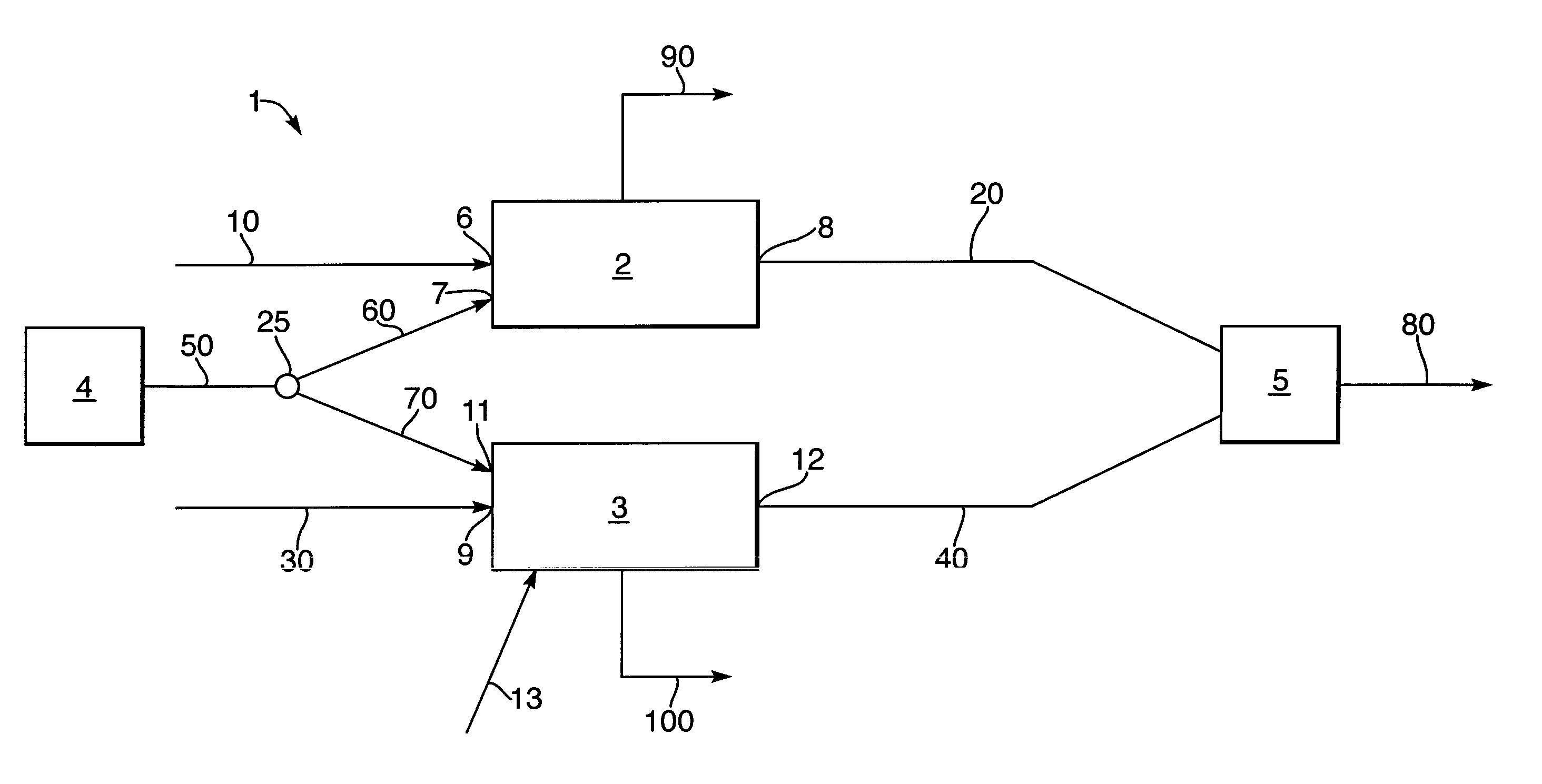

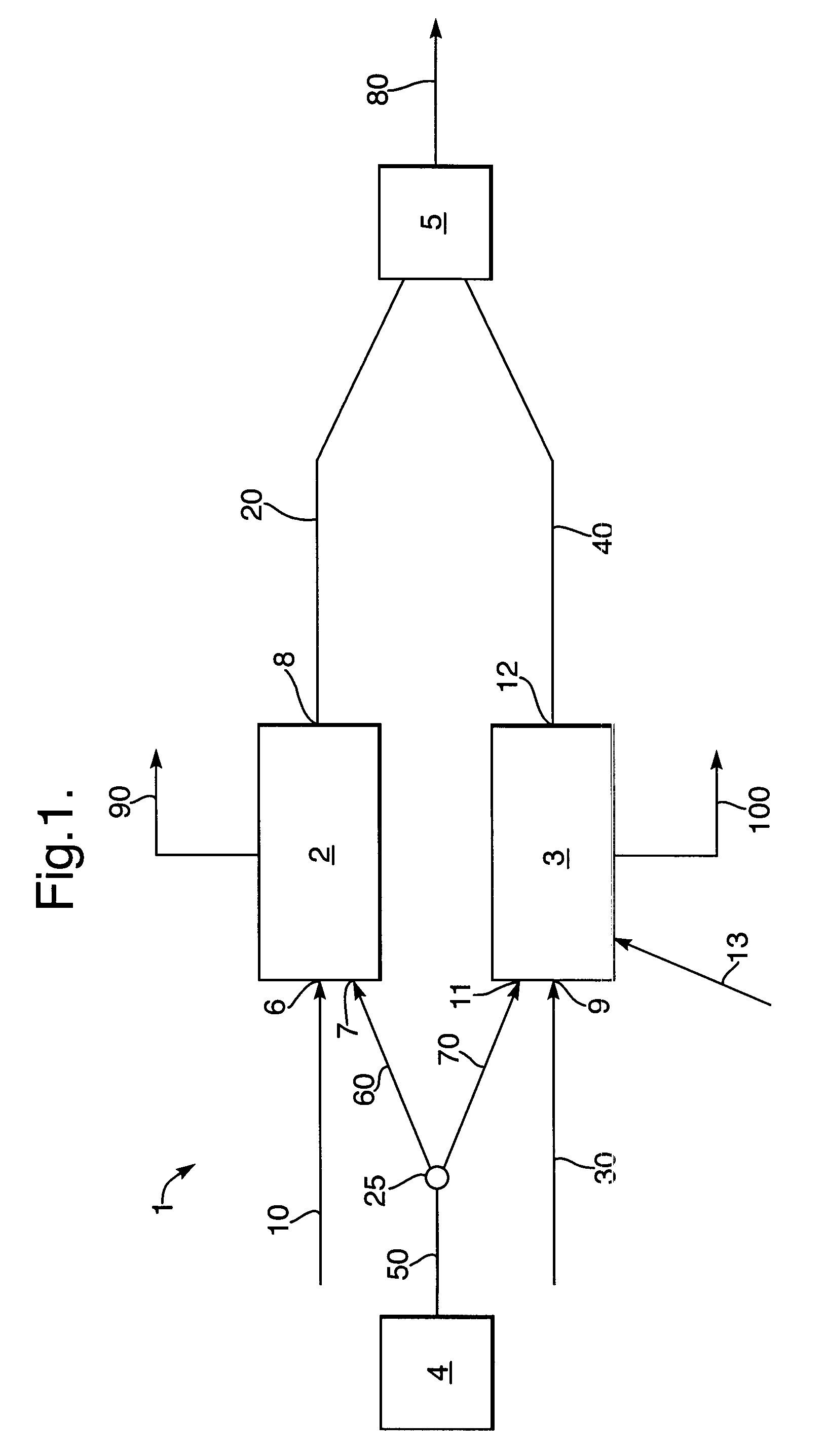

[0045] Reference is made to FIG. 1. FIG. 1 schematically shows a system 1 for producing synthesis gas.

[0046] The system 1 comprises a first gasification reactor 2, a second gasification reactor 3, an oxygen source 4 and a shift converter 5. In the embodiment shown in FIG. 1, the first gasification reactor 2 is a coal gasification reactor and the second gasification reactor 3 is a gas gasification reactor.

[0047] In the system 1 according to FIG. 1 a particulate coal containing stream 10 and an oxygen containing stream 60 are fed at inlets 6 and 7, respectively, into the coal gasification reactor 2.

[0048] Similarly, a gas containing stream 30 and an oxygen containing stream are 70 are fed into the gas gasification reactor 3 at inlets 9 and 11.

[0049] During normal use of the embodiment of FIG. 1 only the coal gasification reactor 2 is in function; the gas gasification reactor 3 functions as a spare unit for producing synthesis gas in case the coal gasification reactor 2 is out of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vol. % | aaaaa | aaaaa |

| vol. % | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com